A device and method for forming microstructures

A technology of microstructure and guiding device, applied in the direction of driving device, feeding device, large fixed member, etc., can solve the problems of insufficient cutting speed and correct surface quality, so as to reduce cutting power noise, avoid vibration, and reduce possible impact. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

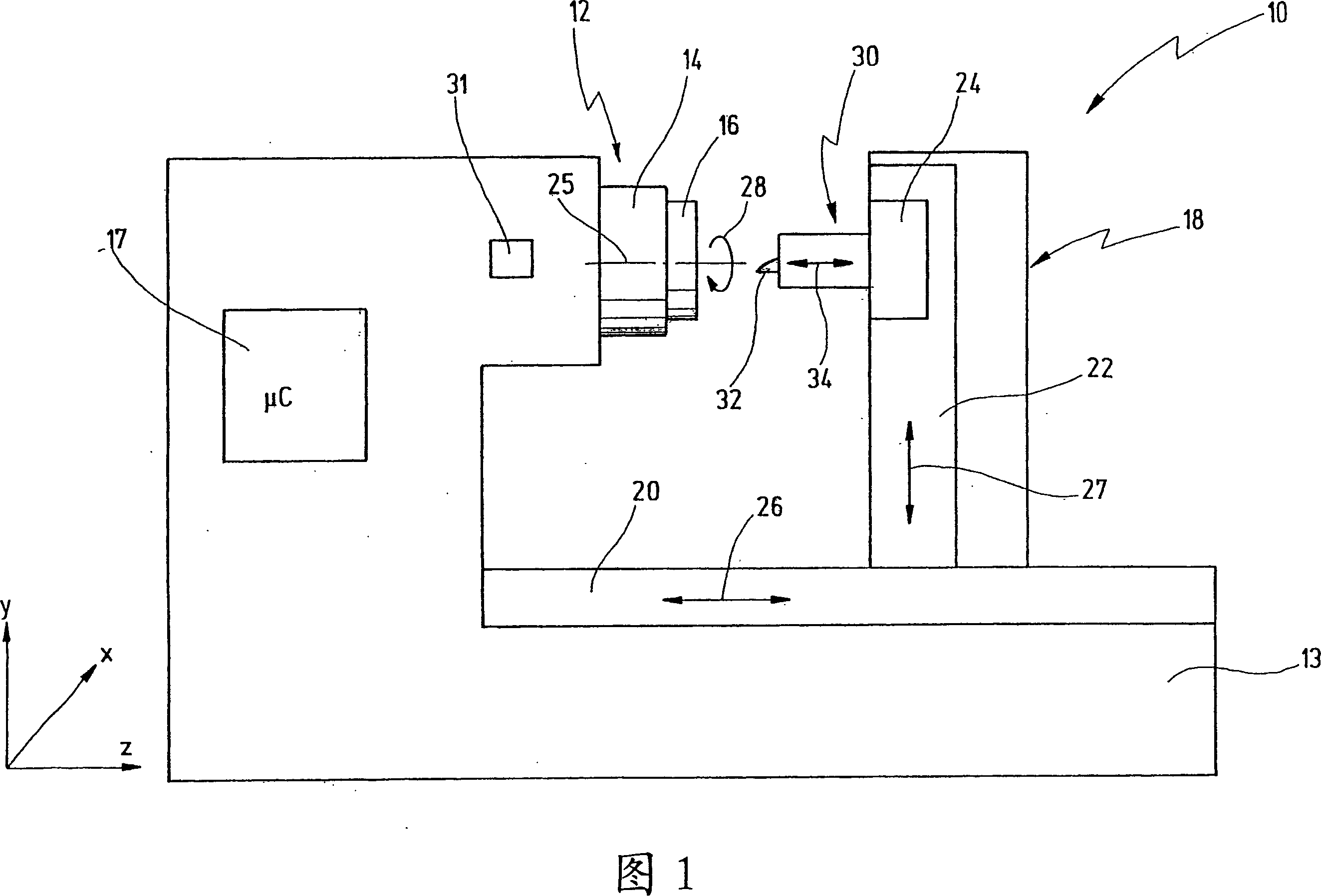

[0090] In FIG. 1 , a device according to the invention is shown very diagrammatically, indicated in its entirety by the reference numeral 10 .

[0091] The device 10 according to the invention is a lathe which is additionally equipped with an actuator 30 for fast piezo-controlled movements of the tool 32 relative to the workpiece 16 . The device 10 includes a main shaft 12 which can be driven to rotate about its main shaft axis 25 as indicated by arrow 28 . Mounted on the spindle 12 is a gripper 14 in the form of a chuck adapted to grip a workpiece 16 . Along a guide extending in the z-direction (parallel to the spindle axis 25 ), a drive 20 is provided on the bed 13 of the device 10 , by means of which the tool carrier 18 can be moved in the z-direction, as indicated by the double arrow 26 . The tool carrier 18 is provided with a drive 22 by means of which the tool carrier 24 can be moved in the vertical direction (y-direction), as indicated by the double arrow 27 . The too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com