Filter glass for cutting fore infrared rays

A filter glass and near-infrared technology, applied in the field of near-infrared cut-off filter glass, can solve the problems of difficulty in disappearing stripes, insufficient weather resistance improvement, large thermal expansion coefficient, etc., and achieves good weather resistance and near infrared cutoff. Excellent properties and small thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] As shown in Table 1, according to the glass composition relative to 100% by weight of P 2 o 5 : 46.0% by weight, Al 2 o 3 : 9.0% by weight, ZnF 2 : 5.0% by weight, BaF 2 : 18.7% by weight, CaF 2 : 1.1% by weight, SrF 2 : 6.8% by weight, NaF: 2.0% by weight, LiF: 9.4% by weight, Y 2 o 3 : Base glass composed of 2.0% by weight, containing CuO: 6.0% by weight, each component raw material was blended.

[0071] Thereafter, the prepared raw materials were melted in a platinum crucible placed in an electric furnace set at 900° C. for 1 hour, and flowed out into a preheated iron plate mold to produce a glass gob. Then, the produced glass block was placed in an electric furnace set at a temperature approximately 50°C higher than the expected glass transition point, and after slow cooling, it was cut and ground to prepare a sample for measuring the thermal expansion coefficient and softening point.

[0072] The results are shown in Table 1, the coefficient of thermal exp...

Embodiment 2~27

[0082] The raw materials of the same components as those in Example 1 were prepared so as to obtain the compositions shown in Tables 1 to 4, glass flakes were produced, and after slow cooling, they were cut out and ground to prepare samples for measuring thermal expansion coefficient and softening point.

[0083] The results are shown in Tables 1-4.

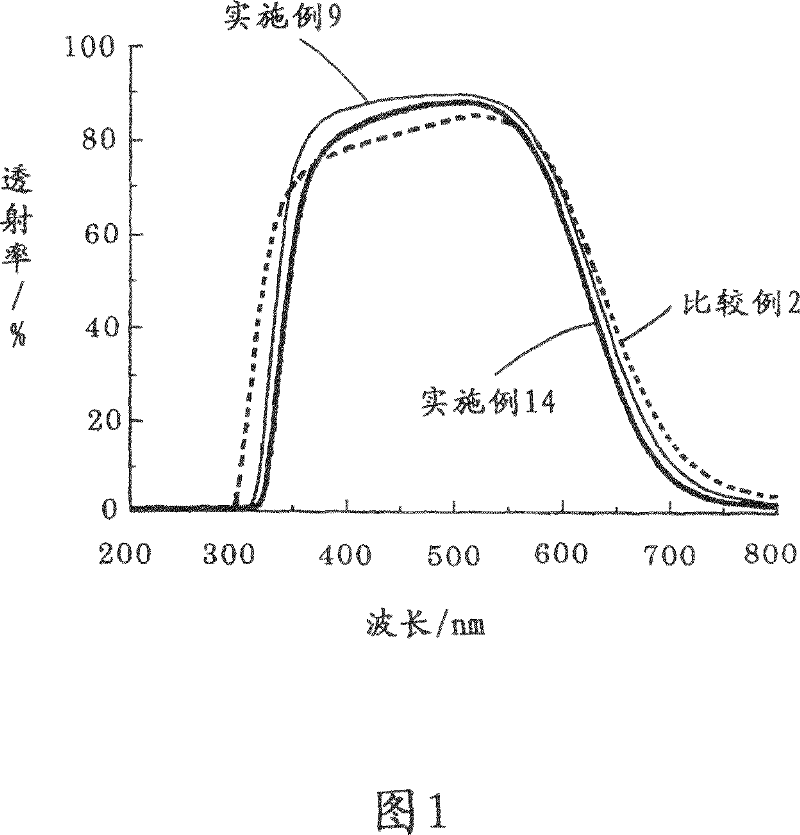

[0084] figure 1 The spectral transmittances of Examples 9, 14, and Comparative Example 2 are shown.

[0085] As evident from Examples 1 to 27 and Comparative Examples 1 and 2 above, it can be seen that the glass of the Examples of the present invention has better weather resistance than the Comparative Examples and is less likely to be cracked due to its small coefficient of thermal expansion. Also in figure 1 From the spectral transmittance curve shown, it can be seen that the glass of the example of the present invention has a higher transmittance at a wavelength of 350 to 600 nm than that of a comparative example, and on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com