Continuous power/liquid mixing apparatus

A mixing device and powder technology, applied in mixers, mixing methods, mixers with rotary stirring devices, etc., can solve the problems of continuous mixing of difficult powders and liquids, complicated device structures, and increased manufacturing costs, etc. Achieve the effect of promoting mixing and dispersion, generation of continuous and uniform mixed fluid, and easy maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

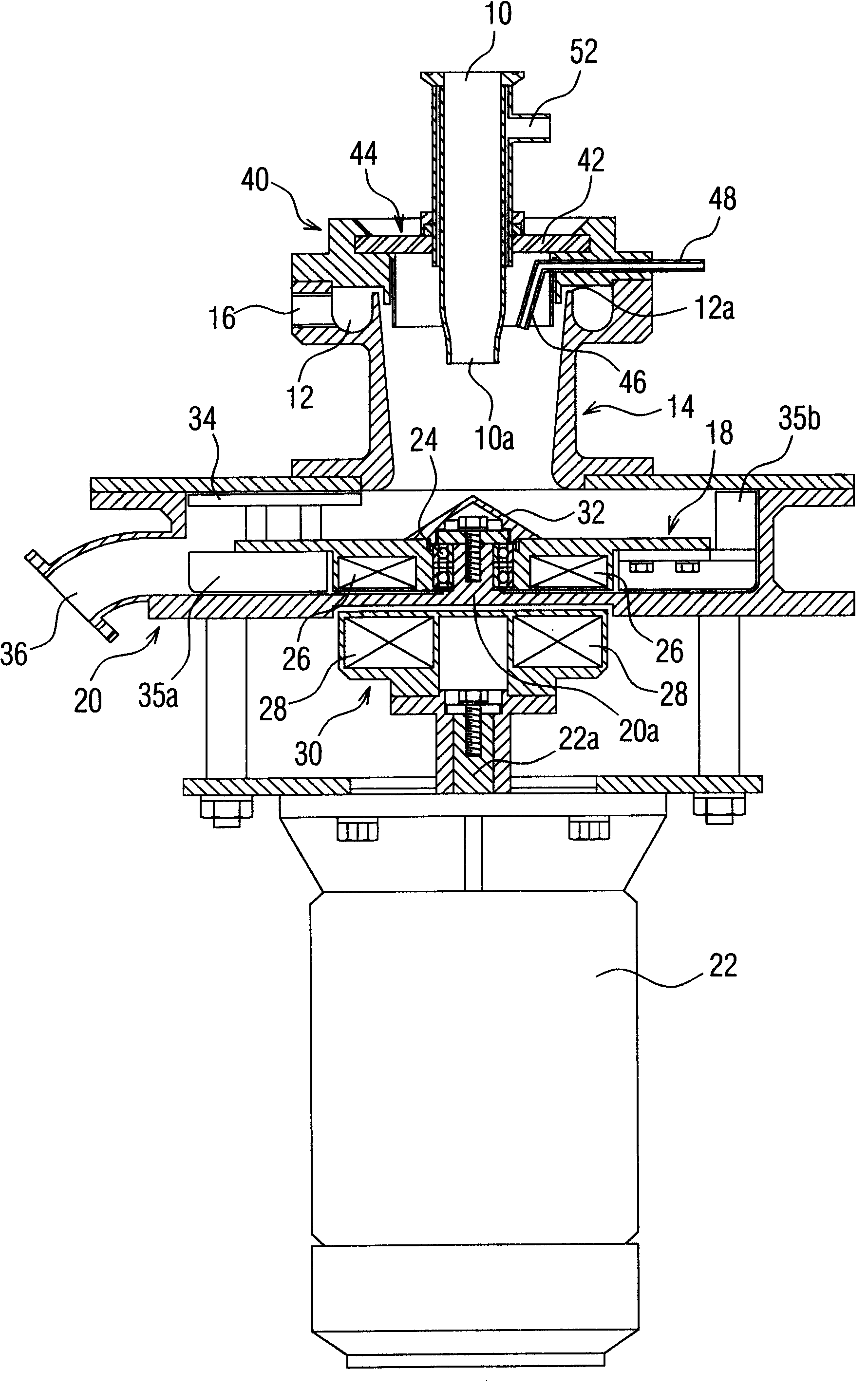

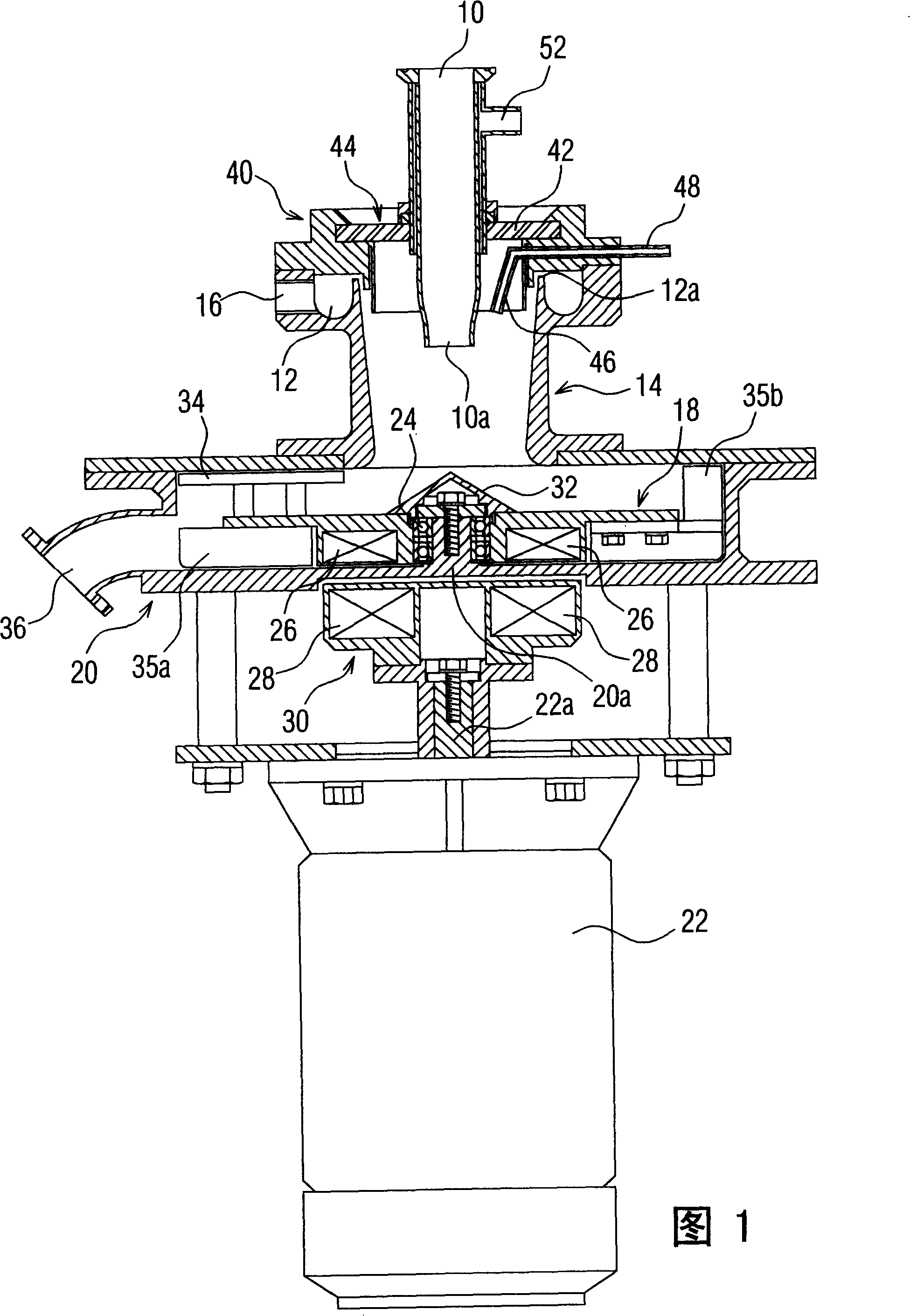

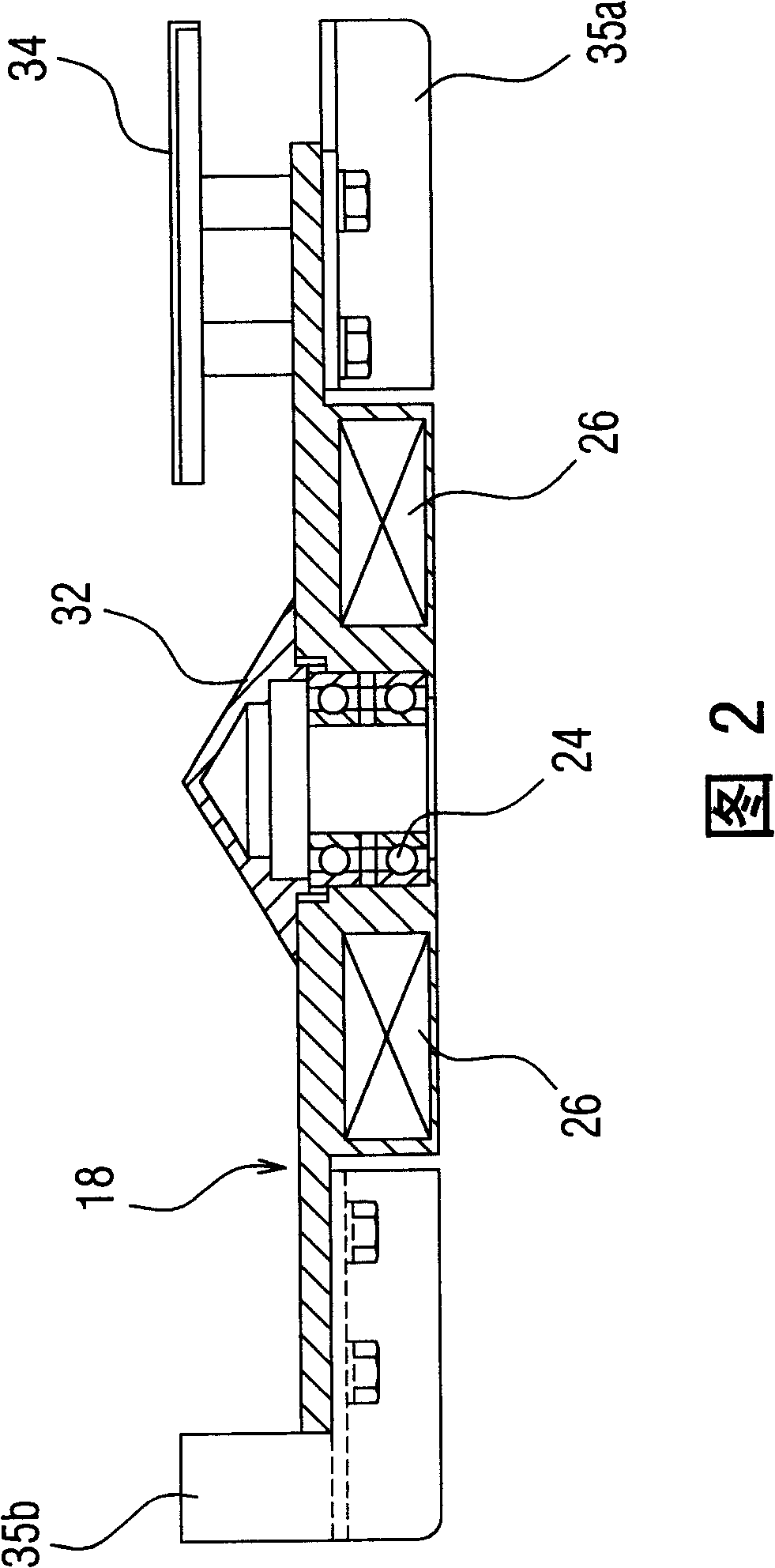

[0051] Next, an embodiment of the powder / liquid continuous mixing device of the present invention will be described in detail below with reference to the drawings.

[0052] 1 to 6 show an embodiment of the powder / liquid continuous mixing device of the present invention. That is, in FIG. 1 , reference numeral 10 denotes a powder supply cylinder connected to a powder quantitative supply device or the like (not shown), and continuously quantitatively supplies required powder. An overflow cone 14 is provided with an inner wall surface that makes the desired liquid form an annular overflow film and flows down from the overflow port edge 12a of the overflow tank 12, so that the opening 10a of the powder supply cylinder 10 surrounding the front end of the powder supply cylinder 10 . In addition, the water supply pipe 16 for continuously supplying the required liquid is properly communicated and connected with the overflow groove 12 on the overflow cone 14 .

[0053] A mixing chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com