Double-layer warp beam warper

A warping machine and warping technology, applied in the field of warping machines, can solve the problems of mechanical wear, high noise, and complicated debugging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

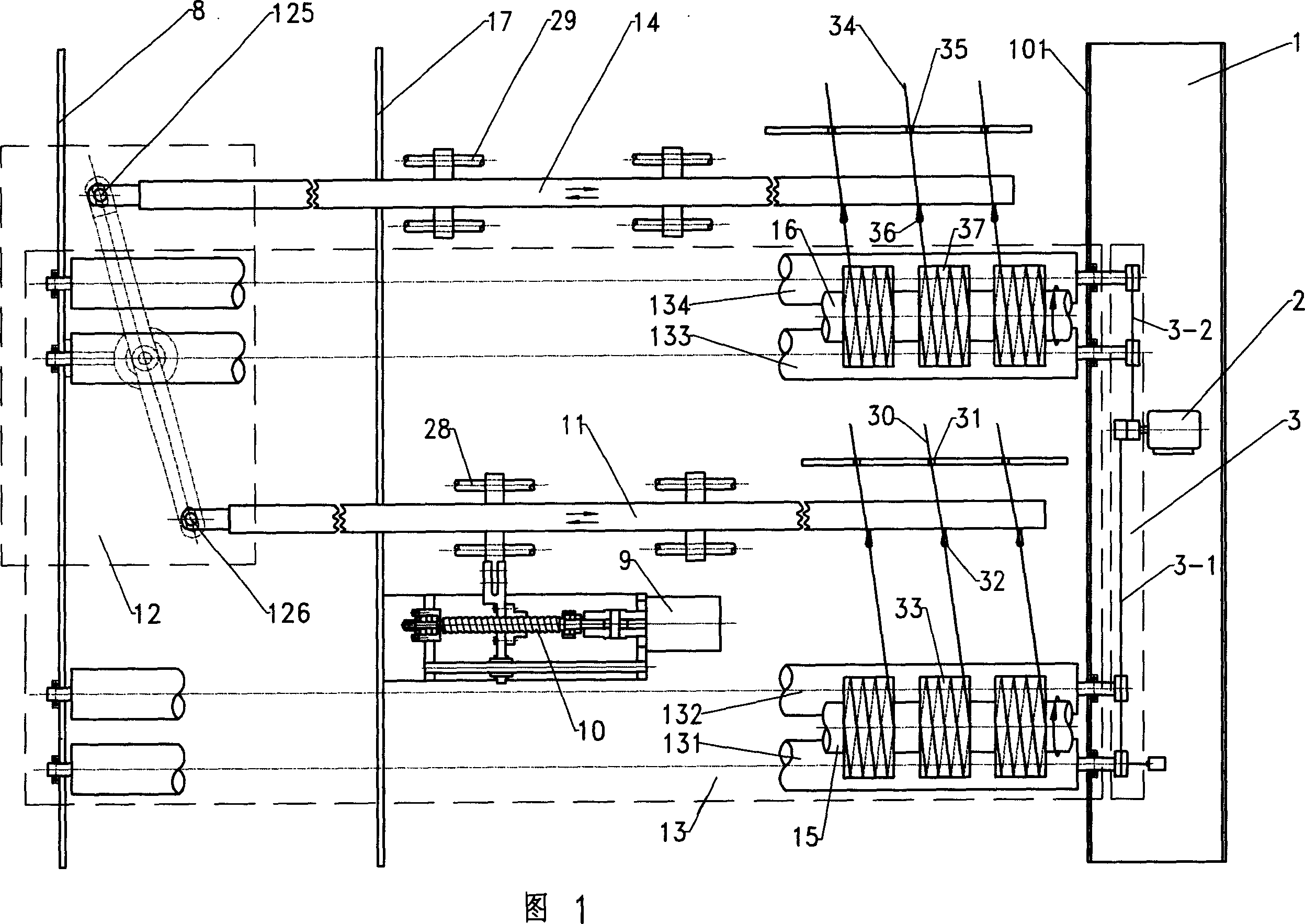

[0013] As can be seen from the structural schematic diagram of a double-layer flower warp beam warping machine shown in Figure 1, it includes a machine head 1, a left wall panel 101 of the machine head, a motor 2, a middle wall panel 17, a tail wall panel 8, a servo Motor 9, ball screw 10, it also comprises connecting rod swing mechanism 12,, double-deck roller mechanism 13 and synchronous transmission mechanism 3; Described connecting rod swing mechanism 12 is fixedly connected with tail wall plate 8, and servo motor 9 passes through The ball screw 10 and the connecting rod swing mechanism 12 push the upper yarn guide needle bed 14 and the lower yarn guide needle bed 11 to reciprocate and swing in the horizontal direction respectively; Between the wallboard 17 and the rear wallboard 8, the motor 2 is driven to run through the synchronous transmission mechanism 3. The motor 2 can be an AC variable frequency motor.

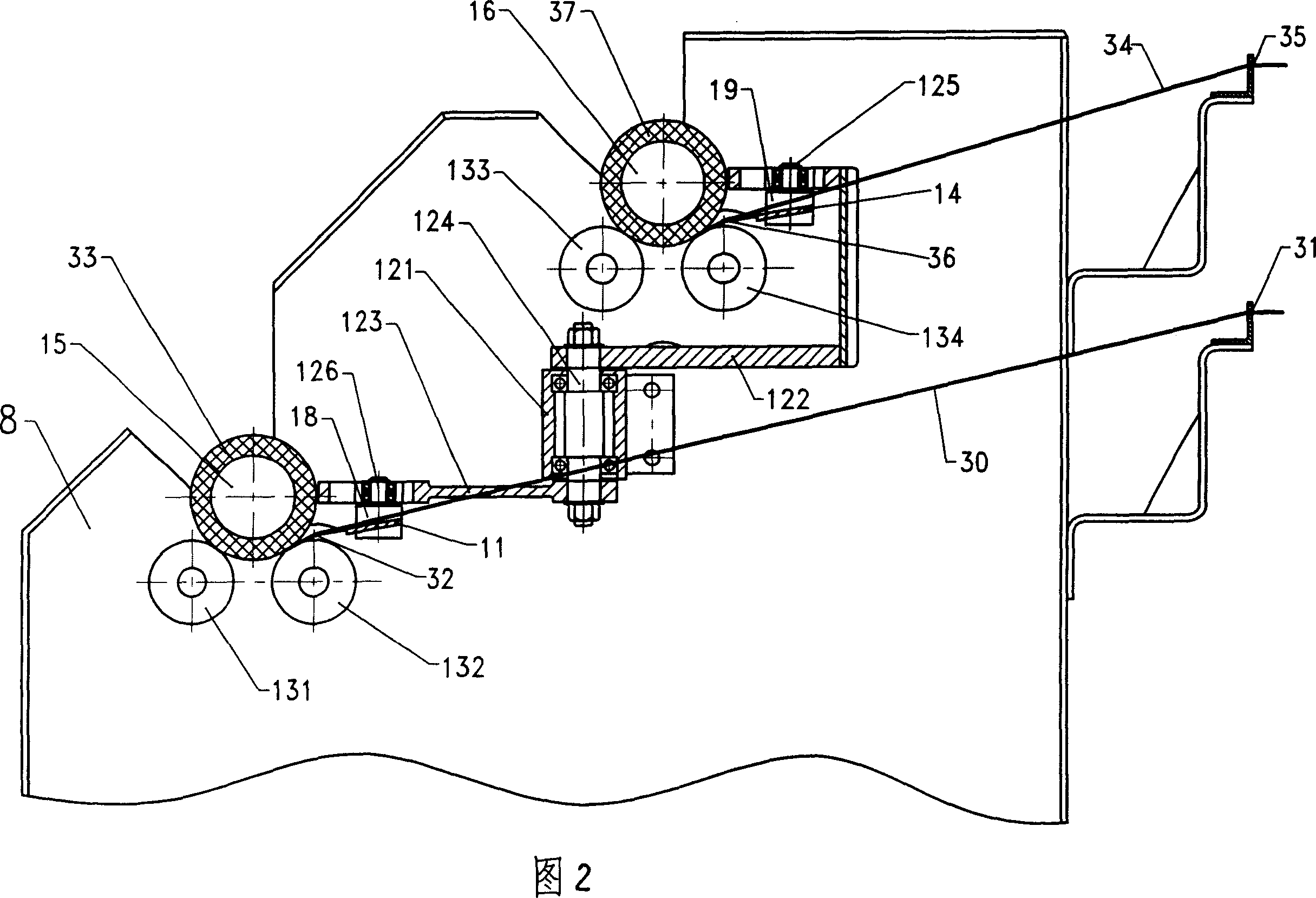

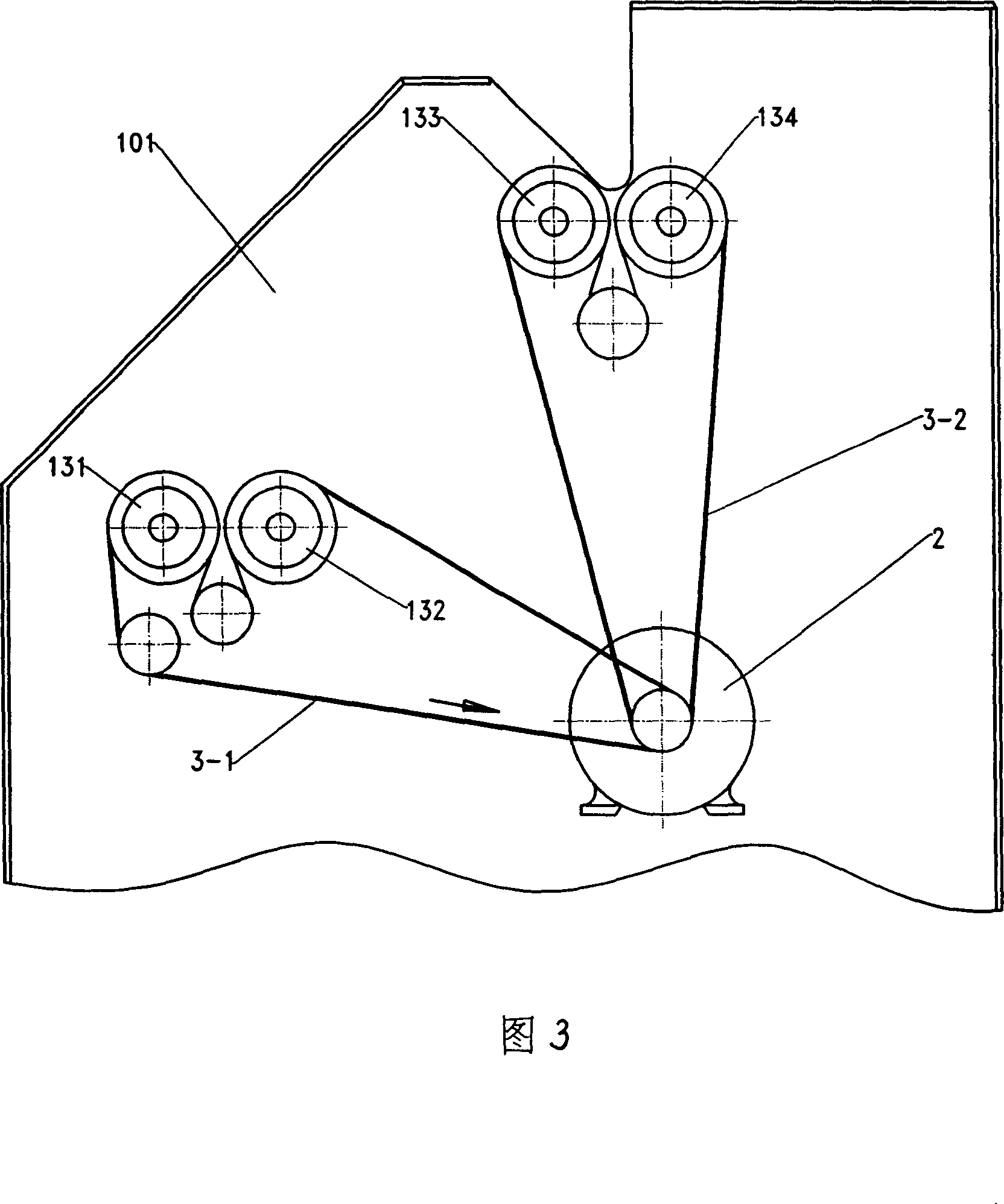

[0014] Fig. 2 is a structural schematic diagram of a link sw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com