Method of extracting, distilling and separating sodium hydroxide in sodium aluminate solution in aluminum oxide producing process

A technology of extractive distillation and sodium hydroxide, applied in the purification of aluminate/alumina/aluminum hydroxide, preparation of alkali metal aluminate/alumina/aluminum hydroxide, alkali metal oxide/hydroxide, etc., It can solve the problems such as the extraction and distillation separation of sodium hydroxide, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

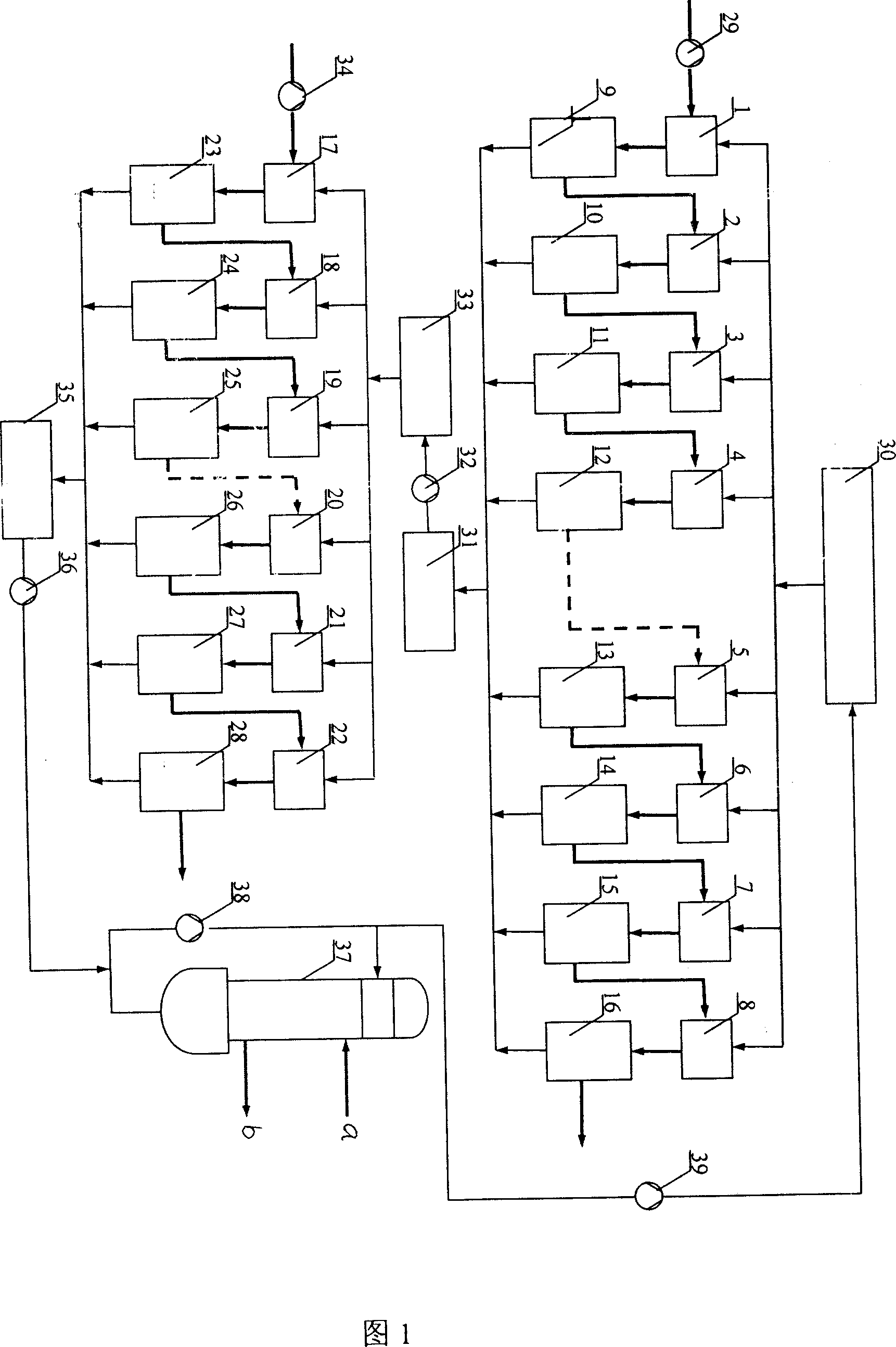

Image

Examples

Embodiment 1

[0025] Raw material: mother liquor evaporated by Bayer method, chemical composition is N K 320g / L, Al 2 o 3 178.4g / L, caustic ratio 2.95; stripping solution is decomposition mother liquor, its chemical composition is N K 165g / L, Al 2 o 3 93.6g / L, caustic ratio 2.90.

[0026] Use n-octanol to extract and evaporate the mother liquor, 45 stages of extraction, the extraction temperature is 90°C, and the reaction time of each stage is 2 minutes; 6 stages of stripping, the stripping temperature is 90°C, and the reaction time of each stage is 2 minutes; The extraction ratio is 2:1; the distillation temperature is 99°C. After evaporating the mother liquor and extracting N K is 370g / L, and the caustic ratio is 1.59; the N K It is 247 and the caustic ratio is 3.4.

Embodiment 2

[0028] Raw material: mother liquor evaporated by Bayer method, chemical composition is N K 320g / L, Al 2 o 3 178.4g / L, caustic ratio 2.95; stripping solution is decomposition mother liquor, its chemical composition is N K 165g / L, Al 2 o 3 93.6g / L, caustic ratio 2.90.

[0029] Use n-octanol to extract and evaporate the mother liquor, 50 stages of extraction, the extraction temperature is 75 ° C, and the reaction time of each stage is 8 minutes; 8 stages of stripping, the stripping temperature is 70 ° C, and the reaction time of each stage is 12 minutes; The extraction ratio is 4:1; the distillation temperature is 87°C. After evaporating the mother liquor and extracting N K is 372g / L, and the caustic ratio is 1.53; the N K It is 243 and the caustic ratio is 3.54.

Embodiment 3

[0031] Raw material: mother liquor evaporated by Bayer method, chemical composition is N K 320g / L, Al 2 o 3 178.4g / L, caustic ratio 2.95; stripping solution is decomposition mother liquor, its chemical composition is N K 165g / L, Al 2 o 3 93.6g / L, caustic ratio 2.90.

[0032] Use n-octanol to extract and evaporate the mother liquor, 20 stages of extraction, extraction temperature 95°C, reaction time of each stage is 2 minutes; 12 stages of stripping, stripping temperature of 90°C, reaction time of each stage is 4 minutes; The extraction ratio is 5:1; the distillation temperature is 99.7°C. After evaporating the mother liquor and extracting N K is 387g / L, and the caustic ratio is 1.46; the N K is 250, and the caustic ratio is 3.45.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com