Gas spring

A gas spring and volume technology, applied in the field of gas springs, can solve the problem of no effective volume expansion, and achieve the effect of preventing vibration and lateral displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

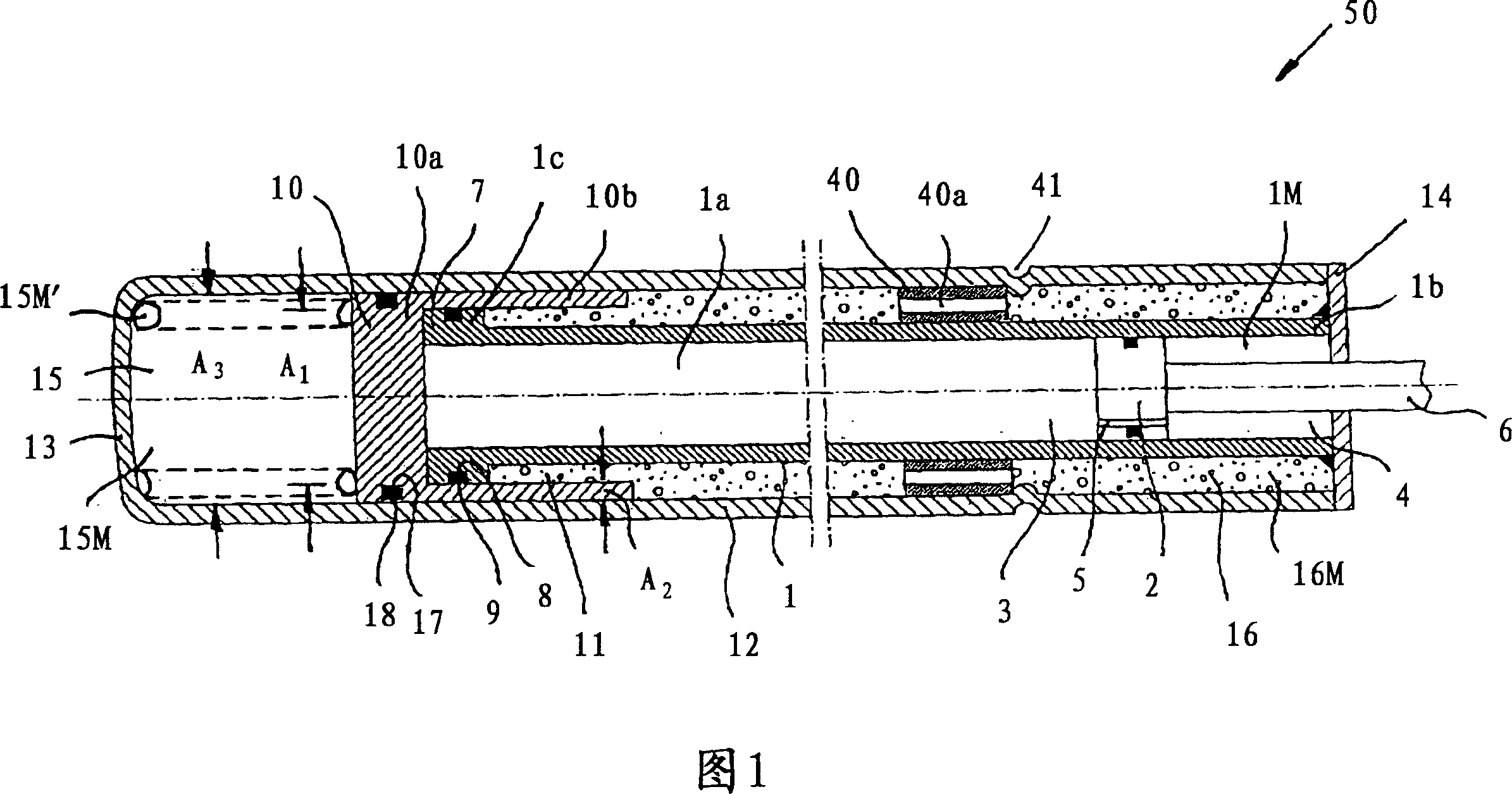

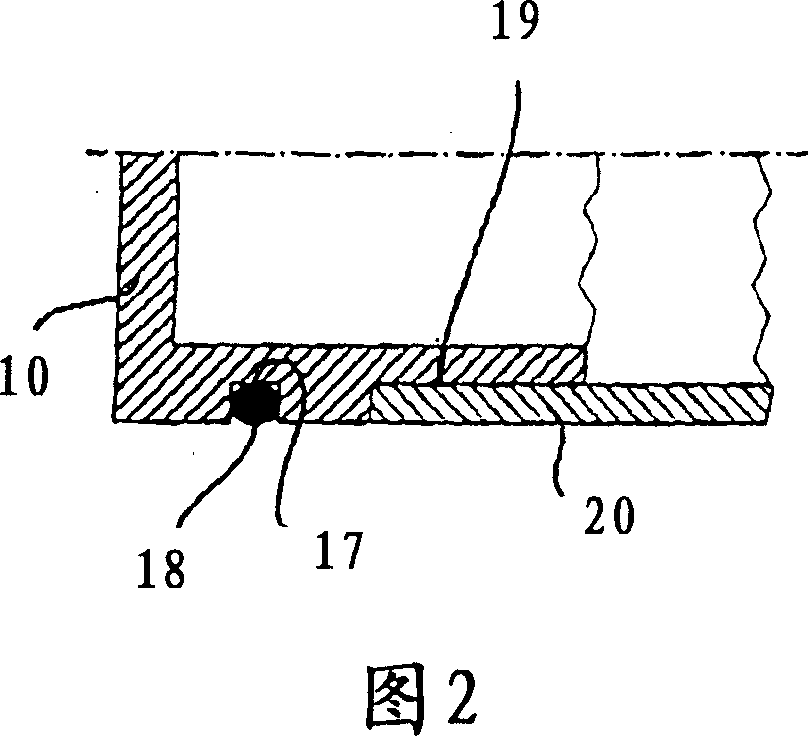

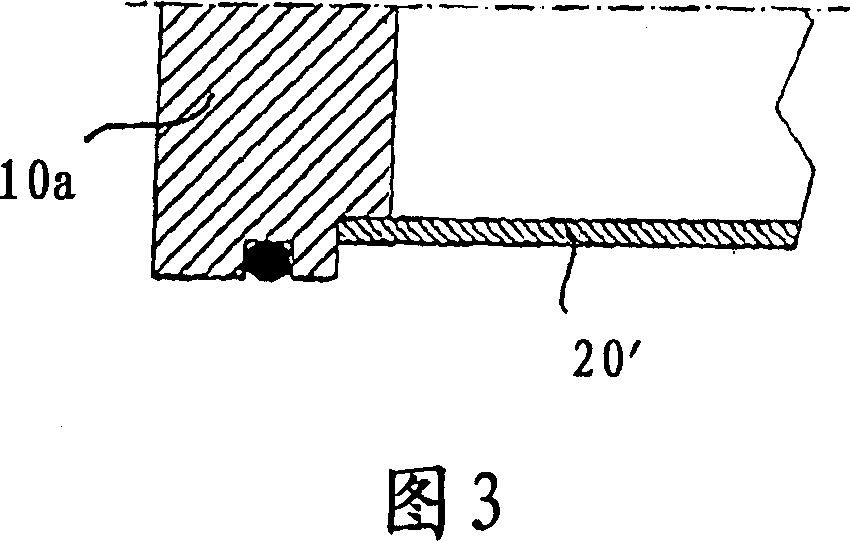

[0045] In FIG. 1 , a gas spring according to the invention is indicated generally at 50 . The gas spring 50 has a working cylinder 1 in which a working piston 2 is displaceably guided. The working piston 2 divides the interior 1 a of the working cylinder 1 into a first working chamber 3 and a second working chamber 4 . The piston rod 6 is fastened to the working piston 2 , passes through the second working chamber 4 , which is closed from the environment, and is guided in a sealed manner outside the gas spring 1 .

[0046] It is thus possible to attenuate the movement of the working piston 2 in the inner chamber 1a of the working cylinder 1, which is filled with compressed gas 1M, the orifice 5 connecting the first working chamber 3 with the second working chamber 4 is provided In working piston 2. However, in addition to or as an alternative to the orifice 5 , at least one longitudinal groove can also be formed in the cylinder 1 .

[0047] The open end 1 c of the working c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com