Booster-type compressor

A technology for compressors and compressed gases, which is applied in the direction of liquid variable displacement machinery, mechanical equipment, machines/engines, etc., and can solve problems such as temperature rise and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

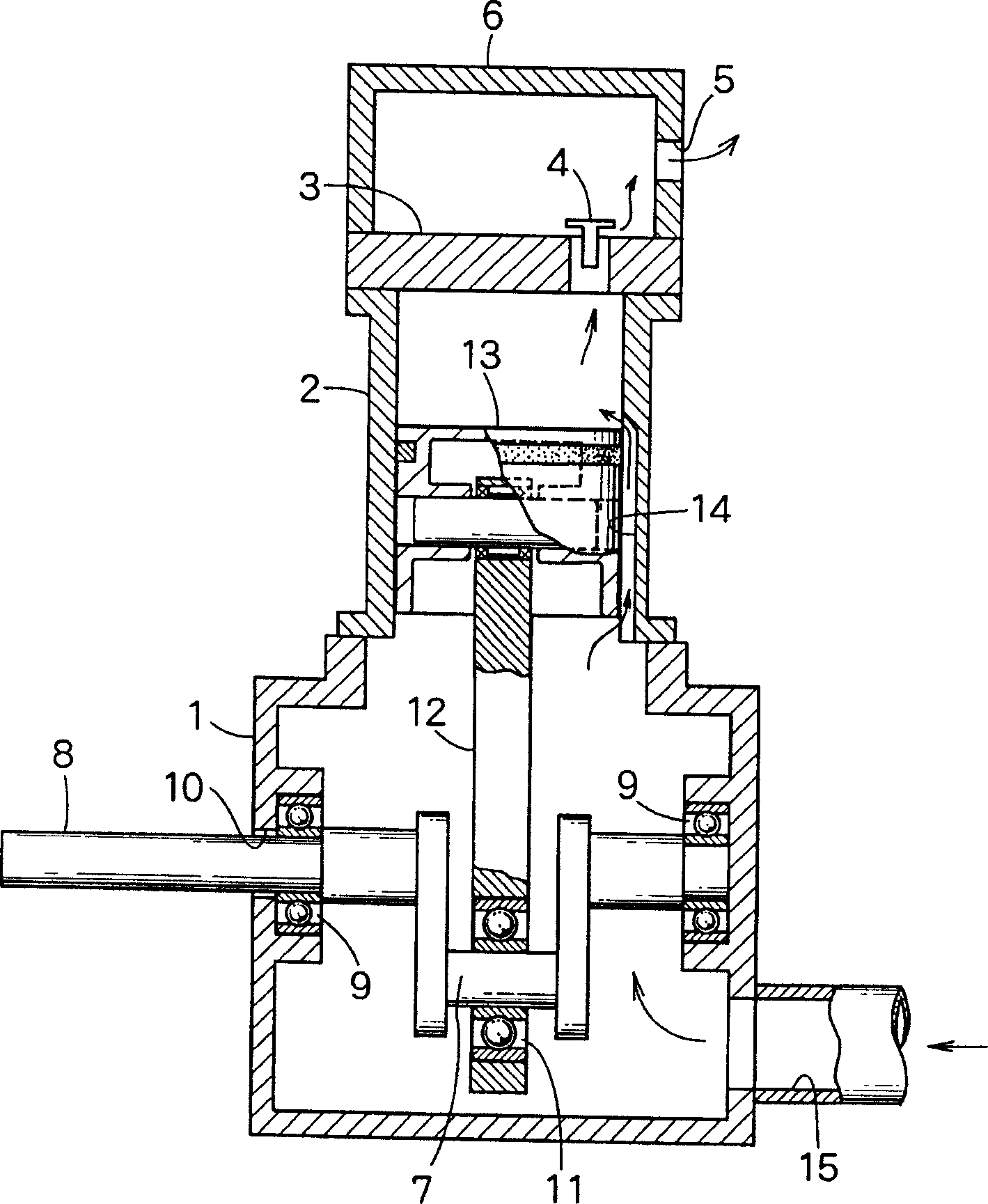

[0011] Below, will refer to figure 1 , the booster compressor of the present invention will be described.

[0012] In the upper part of the crankcase 1, a discharge check valve 4 is provided in the top wall 3 of the cylinder 2, and above the top wall 3, a discharge chamber 6 with a discharge hole 5 is provided.

[0013] In the crankcase 1, a drive shaft 8 is rotatably mounted via bearings 9, 9 and seals 10, which is integrally connected with the crankshaft 7 and driven by a suitable power source. The piston rod 12 is rotatably connected to the crankshaft 7 via a bearing 11 at one end, and is rotatably connected to the piston 13 in the cylinder 2 at the other end.

[0014] A gas guide groove 14 is formed on the inner periphery of the cylinder 2 . When the piston 13 is at the lowest position, the lower end of the gas guiding groove 14 communicates with the inside of the crankcase 1 , and the upper end of the gas guiding groove 14 communicates with the space above the piston 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com