Hinge for mounting in an opening

A hinge and thin-walled technology, applied in the field of hinges, can solve problems such as inability to assemble, missing parts, gaps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

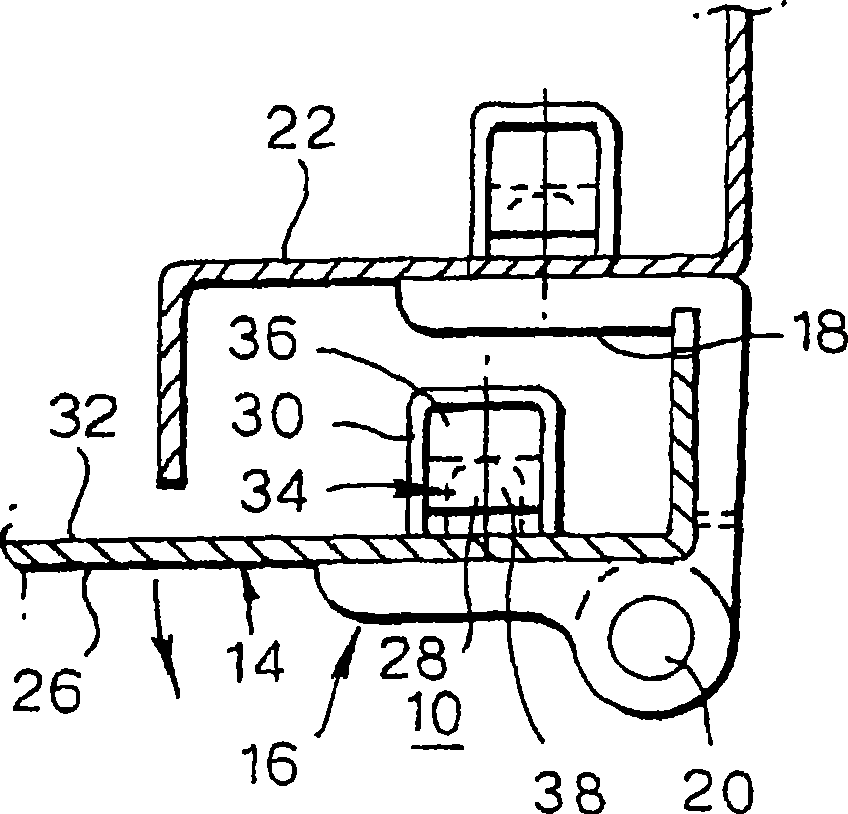

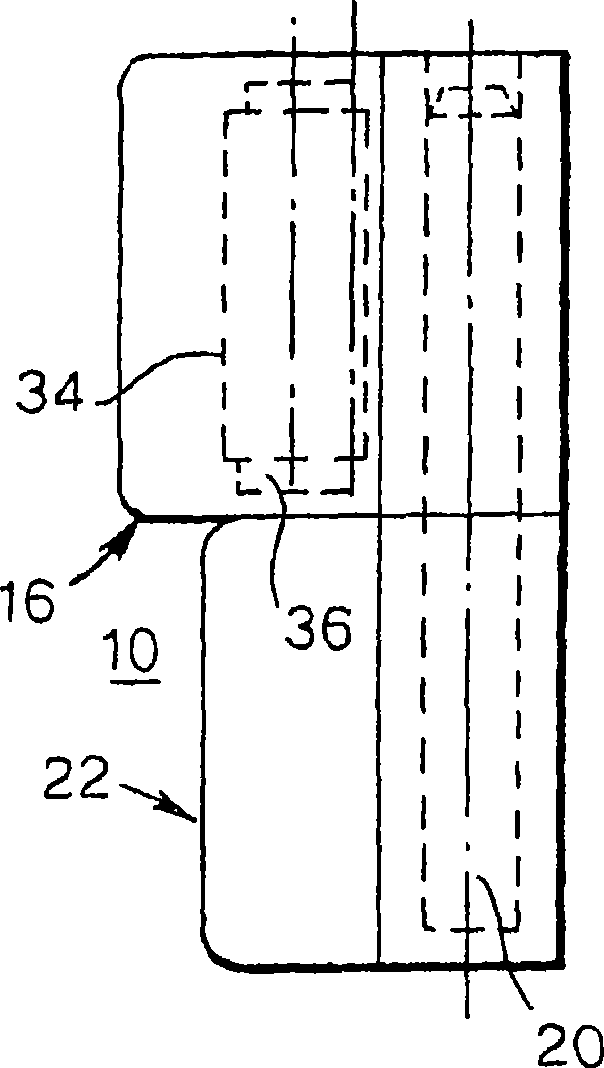

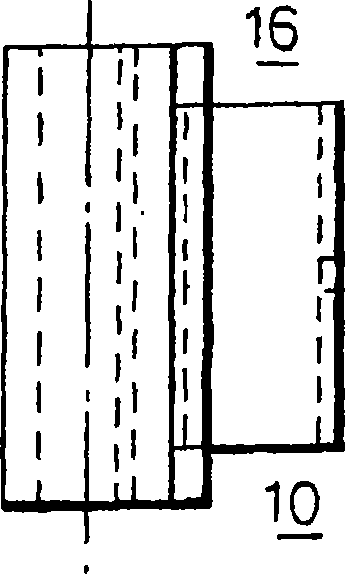

[0086] Figure 1A , 1B , 1C and 1D show in different views a hinge 10 made in accordance with the invention having at least one mounted in a thin wall 14 such as a cabinet door 14 (see for example figure 2 ) the hinge part 16 and another hinge part 18 in the rectangular opening 12, this other hinge part is connected rotatably with the first hinge part by means of a hinge pin 20 and can be fixed on the door frame 22, see Figure 1A . The respective hinge part 16 or 18 mounted on the cabinet door 14 (also on the frame 22) comprises a head 28 covering the edge 24 of the opening 12 in the thin wall 14 or 22 on the (outer) side 26 of the thin wall, A plate such as a flange or (here) a hinge, and a stop part 34 carried by the body supported on the other (rear) side 32 and separated from the body 30, wherein the stop part 34 is supported by the stop element 36, the stop element 36 protrudes flexibly from the body 30 along the outer surface of the body and the free end of the stop e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com