High magnetic conductivity Rogowski coil with air-gap iron core

A technology with high magnetic permeability and iron core, which is applied in the direction of coils, coil manufacturing, electrical components, etc., can solve the problems of insufficient driving capacity and too small output signal, and achieve consumption saving, increased output signal, and easy signal processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

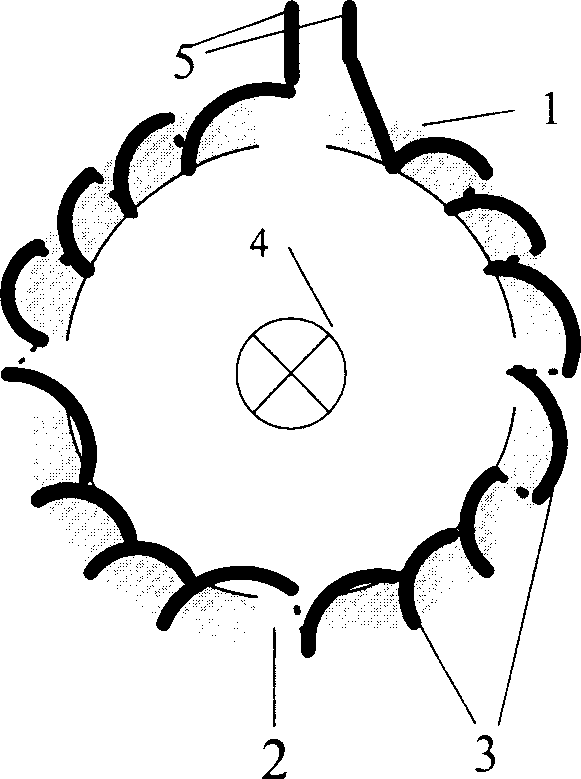

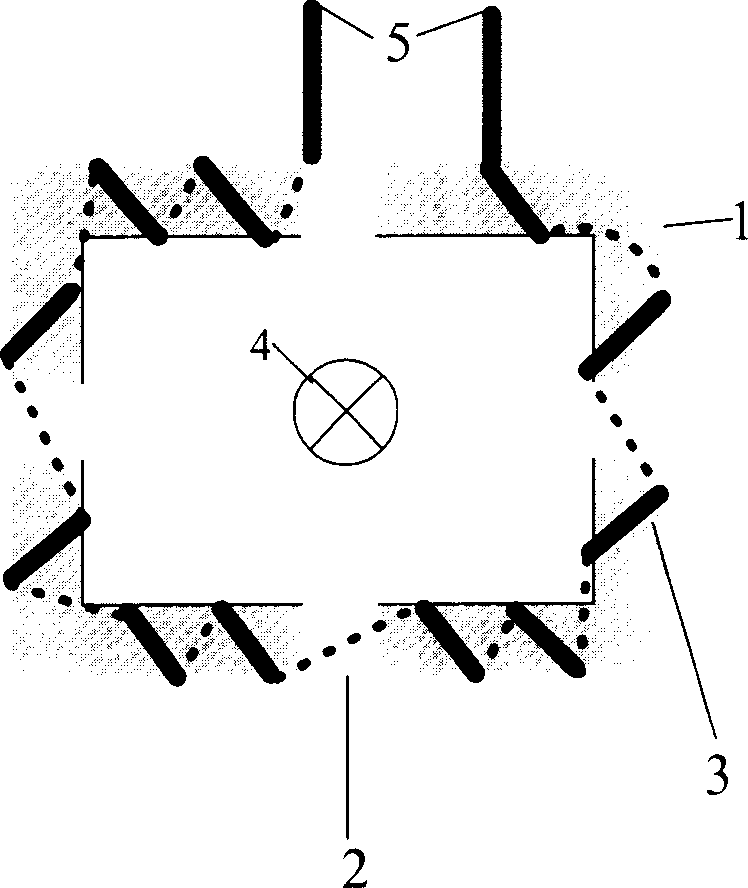

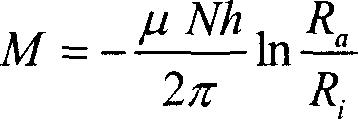

[0022] The high-permeability Rogowski coil of the present invention adopts an air-gap iron core as a skeleton, and its purpose is to increase its mutual inductance coefficient, so that the induced potential is enhanced, so as to facilitate circuit processing and direct supporting use with secondary instruments. The implementation is:

[0023] 1. The design of the air gap iron core. First, according to the specific application environment, mainly the shape and physical size of the primary current-carrying wire to determine the shape and basic dimensions of the Rogowski coil bobbin, including outer diameter, inner diameter and height; then, determine the material of the iron core according to the frequency range of the measured current , medium and low frequencies generally use silicon steel sheets, and for ultra-high frequency applications, materials with good frequency performance are generally used, such as nanocrystalline or amorphous; finally, the number of air gaps is sele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com