Metallic container closure having internal pressure release function

A container cap, metal technology, applied in the directions of bottle/container cap, capping the container tightly with the cap, sealing the cap, etc., can solve the problems of container destruction, container rise, container cap flying out, etc., to prevent bad situations, reliable The effect of gas discharge

Active Publication Date: 2010-08-18

JAPAN CROWN CORK CO LTD

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, in metal sheets made of high tensile strength, for example, the tensile strength is 200 to 230N / mm 2 When a thin plate made of aluminum base alloy (Aluminum Base Alloys) forms a thin shell, the drop impact resistance is improved, and the breakage of the bridging portion between the gaps caused by the drop impact can be effectively prevented, but on the contrary, due to the rise of the internal pressure, the gap The bridging part is not broken, and the internal pressure is not released, so the internal pressure of the container may rise excessively, and the top wall of the container cap may fly out or the container may be damaged.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

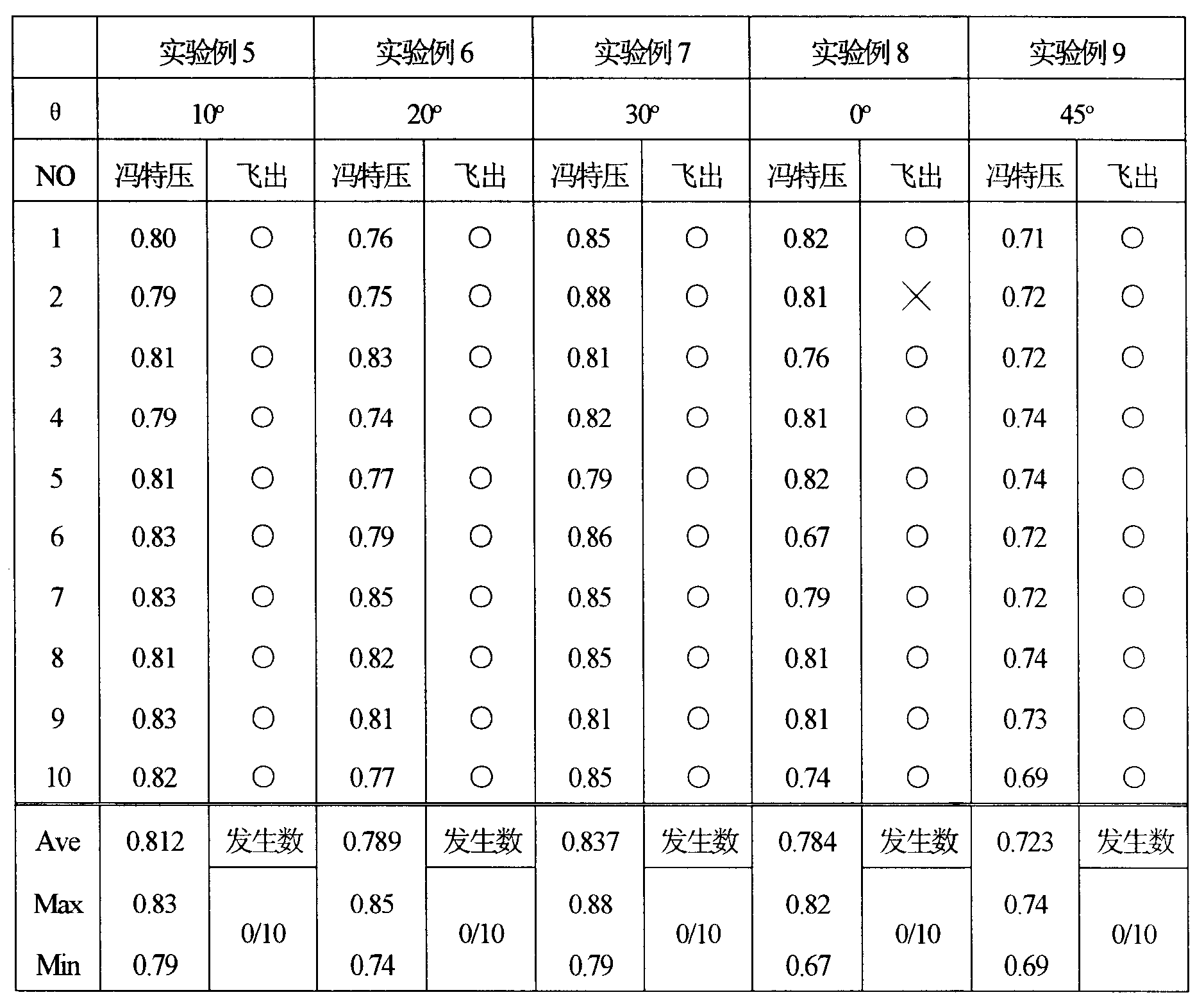

experiment example 1

experiment example 2

experiment example 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

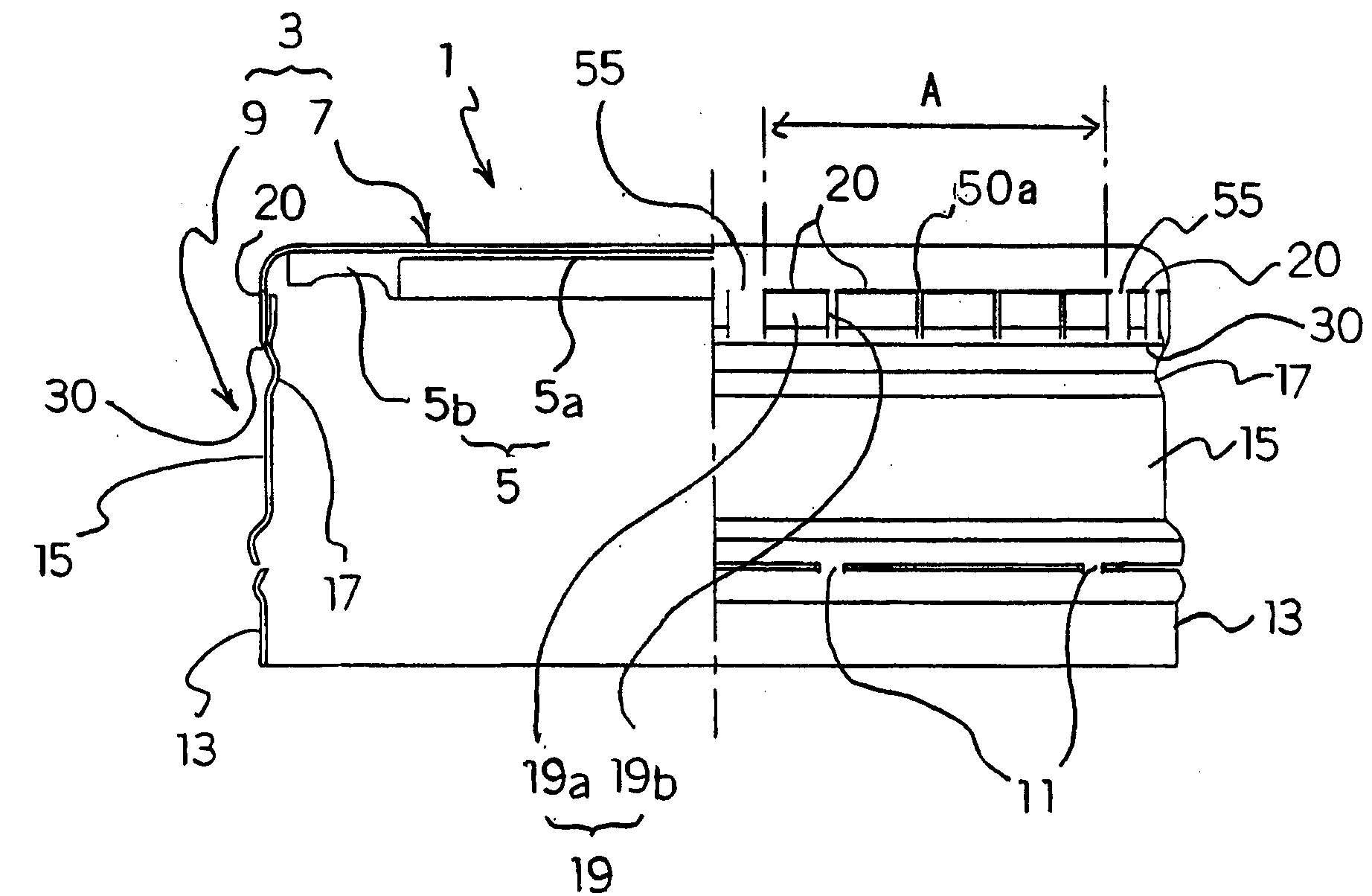

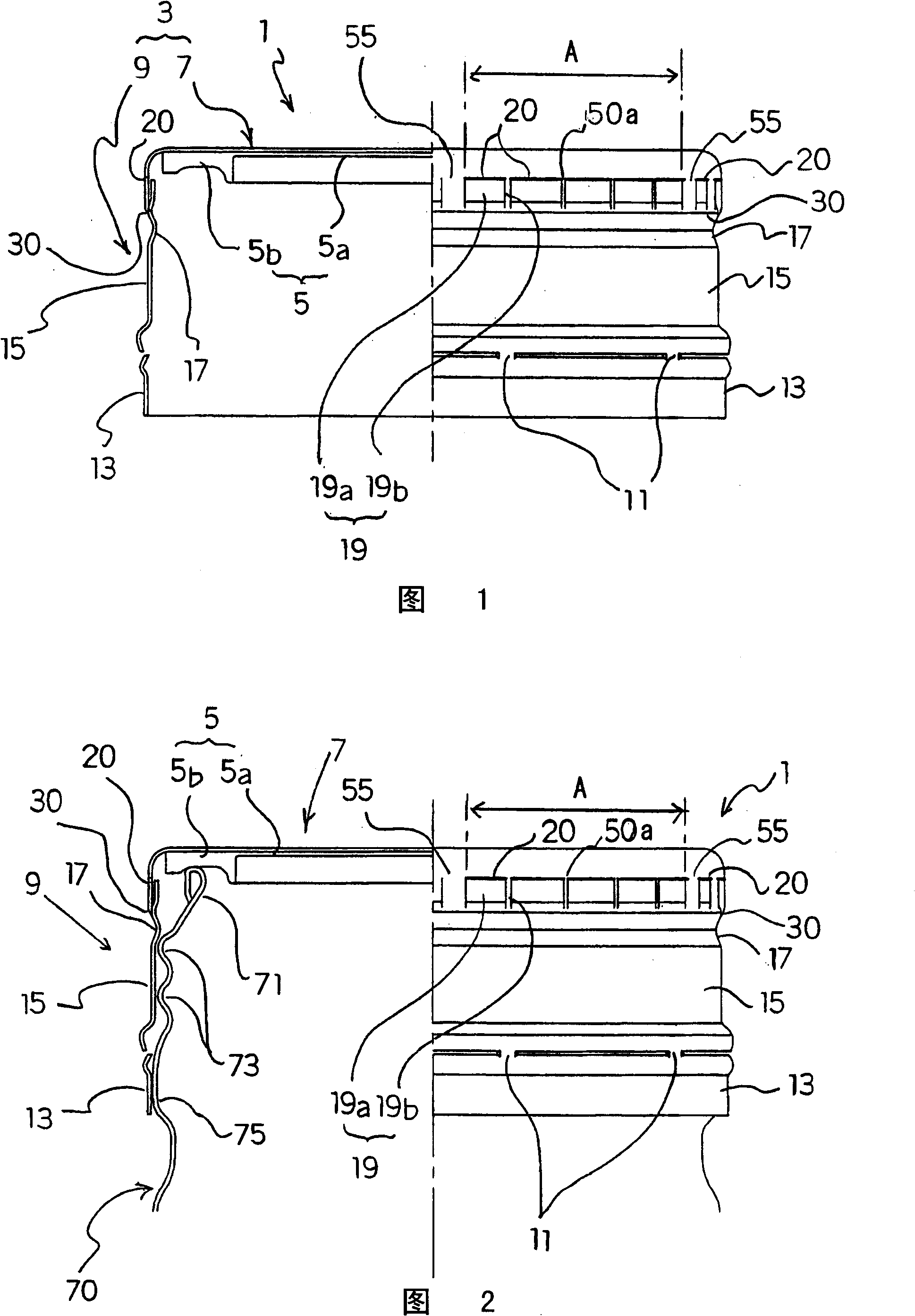

A metallic container closure of the invention comprises a shell of a thin metal sheet having a circular top panel wall (7) and a skirt wall (9) , and a synthetic resin liner arranged in the shell, the skirt wall (9) having a thread-forming region and an annular groove (17) positioned at an upper end portion of the thread-forming region, wherein an internal pressure release line A extending in thecircumferential direction is arranged in the skirt wall (9) at a portion over the annular groove (17), and annular bead (30) is arranged so as to pass through between the internal pressure release line (A) and the annular groove (17). The metallic container closure effectively releases the gas when the pressure in the container is elevated and effectively prevents the skirt wall from being deformed at a portion where the internal pressure release line (A) is formed when it is being wrap-seamed with the mouth-and-neck portion of the container.

Description

technical field The present invention relates to a metal container cap having an internal pressure releasing characteristic, that is, a characteristic of automatically releasing the internal pressure of the container when the internal pressure of the container rises excessively. Background technique Generally, after filling carbonated beverages, etc. into the container, a container cap is attached to the mouth and neck of the container to seal the mouth and neck, and when the contents of the container are overheated, the internal pressure of the container phenomenon of excessive rise. In addition, when the container cap is detached from the mouth and neck of the container, and then the container cap is attached to the container mouth and neck again to seal the container, the internal pressure of the container may rise excessively when the contents rot and ferment. When the internal pressure of the container increases as described above, the cap of the container may fly out...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B65D51/16B65D41/00B65D81/20

CPCB65D41/045B65D41/348B65D51/1638B65D2543/00277

Inventor 市村克仁土屋刚一松本伸也中岛寿熊田光雄皆藤清久

Owner JAPAN CROWN CORK CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com