Control system of well mouth release valve

A control system and safety valve technology, applied in wellbore/well valve devices, wellbore/well components, earthwork drilling, etc. The effect of protecting oil and gas resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

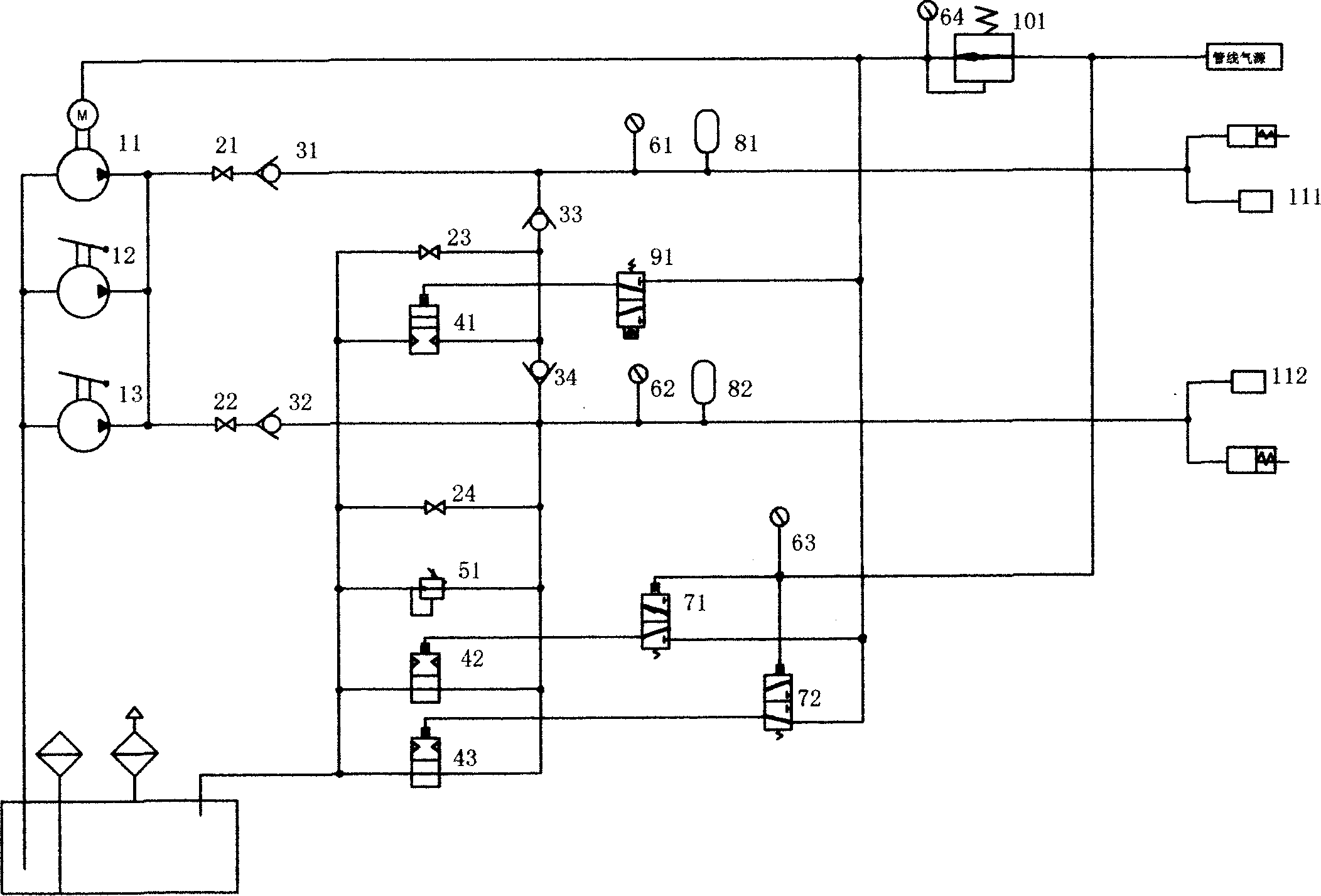

[0015] See figure 1 , A wellhead safety valve control system, including a high-pressure pump 11, manual pumps 12, 13, and a ground safety valve control circuit. The ground safety valve control circuit includes a stop valve 22, a one-way valve 32, a pressure gauge 62, and an accumulator 82. The four are connected in sequence, and an overflow valve 51 is set between the one-way valve 32 and the pressure gauge 62. One end of the stop valve 22 is connected to the high-pressure pump 11, and one end of the accumulator 82 is connected to a ground safety valve. The stop valve 22 is A high-pressure needle valve. The high-pressure pump 11 is a pneumatic booster pump and is connected to a pipeline air source. A high-pressure needle valve 24 is provided between the one-way valve 32 and the pressure gauge 62 in the ground safety valve control loop. A downhole safety...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com