Vertical heat treatment apparatus and method for operating same

一种热处理装置、热处理炉的技术,应用在薄料处理、运输和包装、电气元件等方向,能够解决空间增大占用面积、限制可保管载体数量等问题,达到实现产量、产量提高、实现保管数量的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

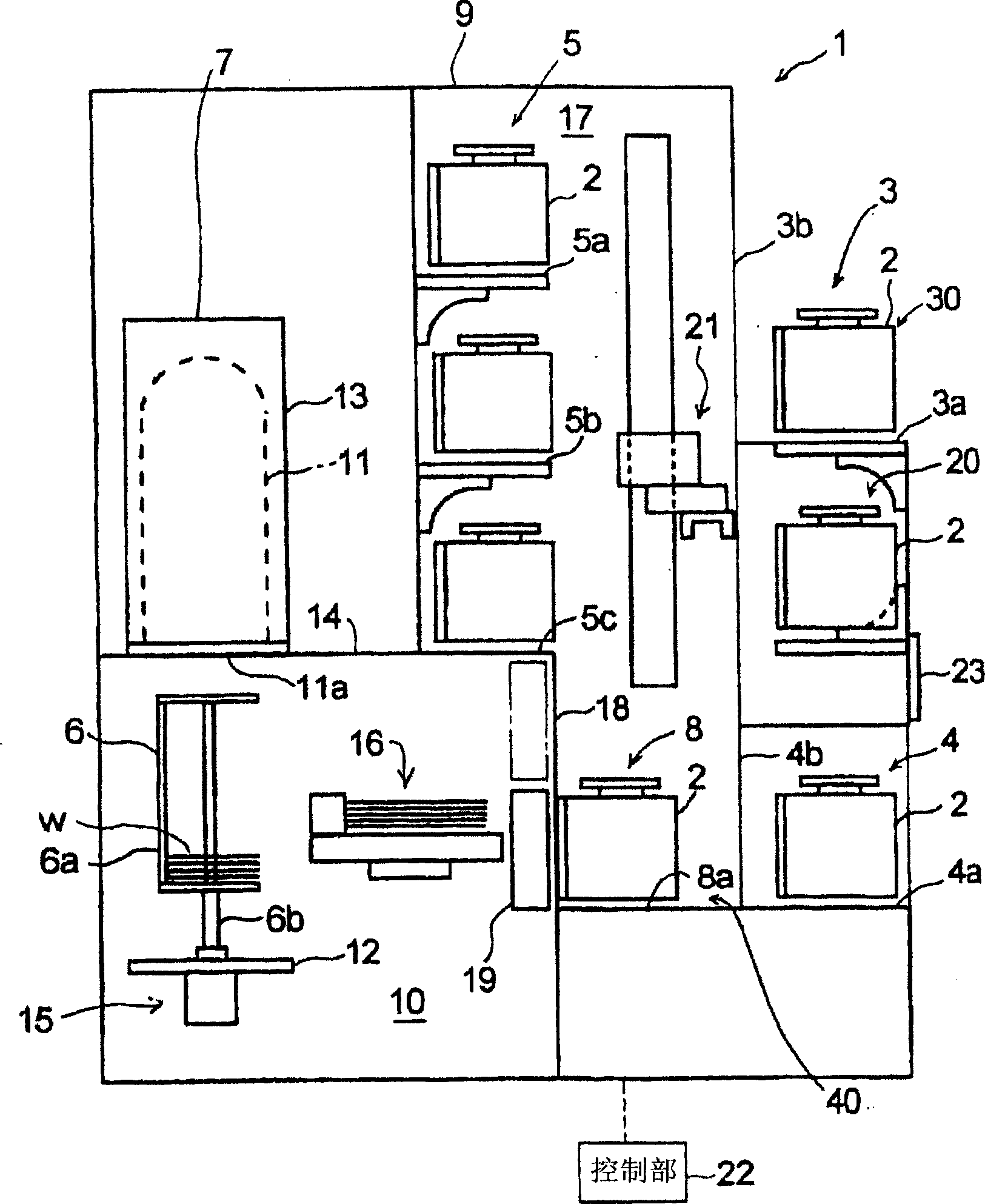

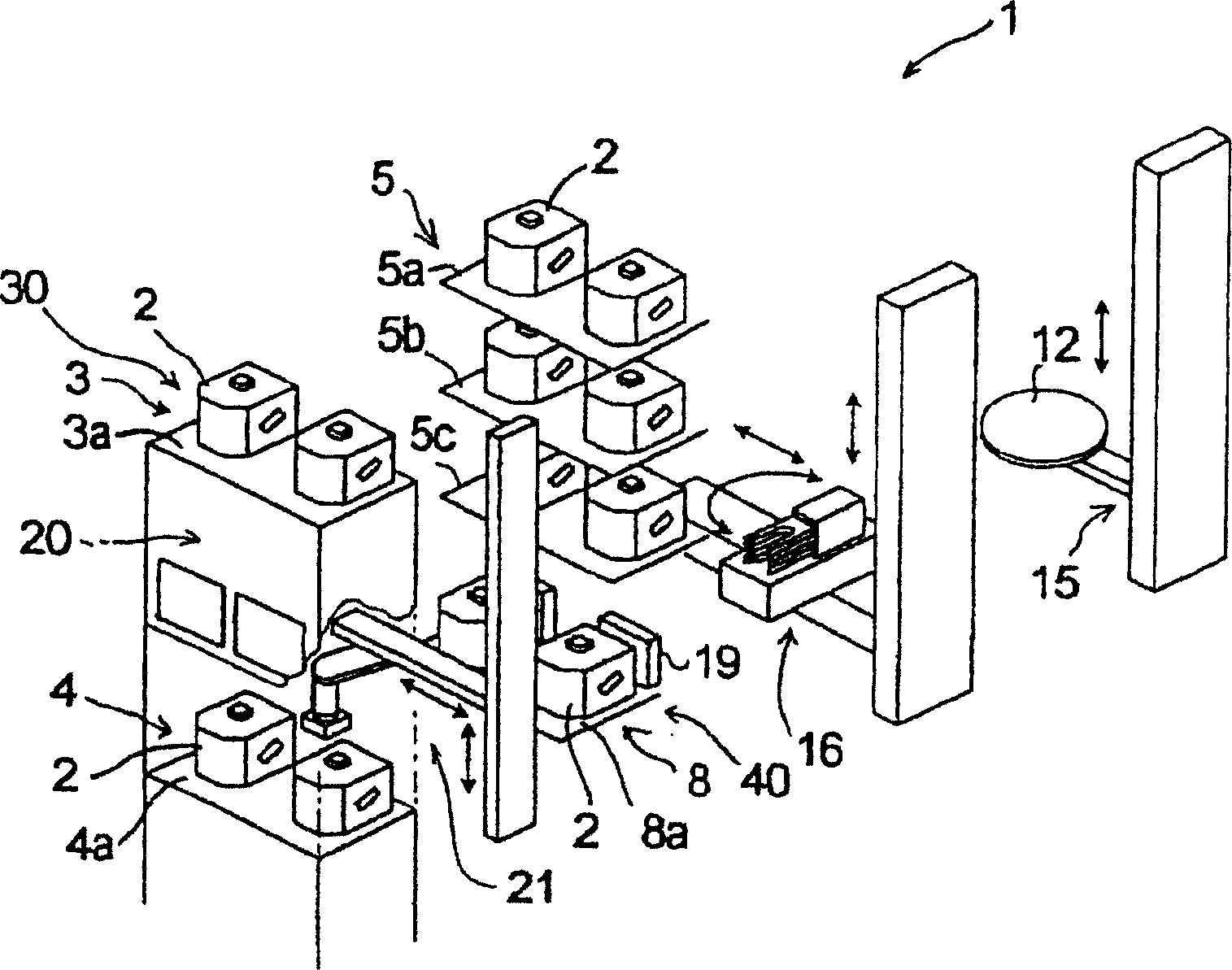

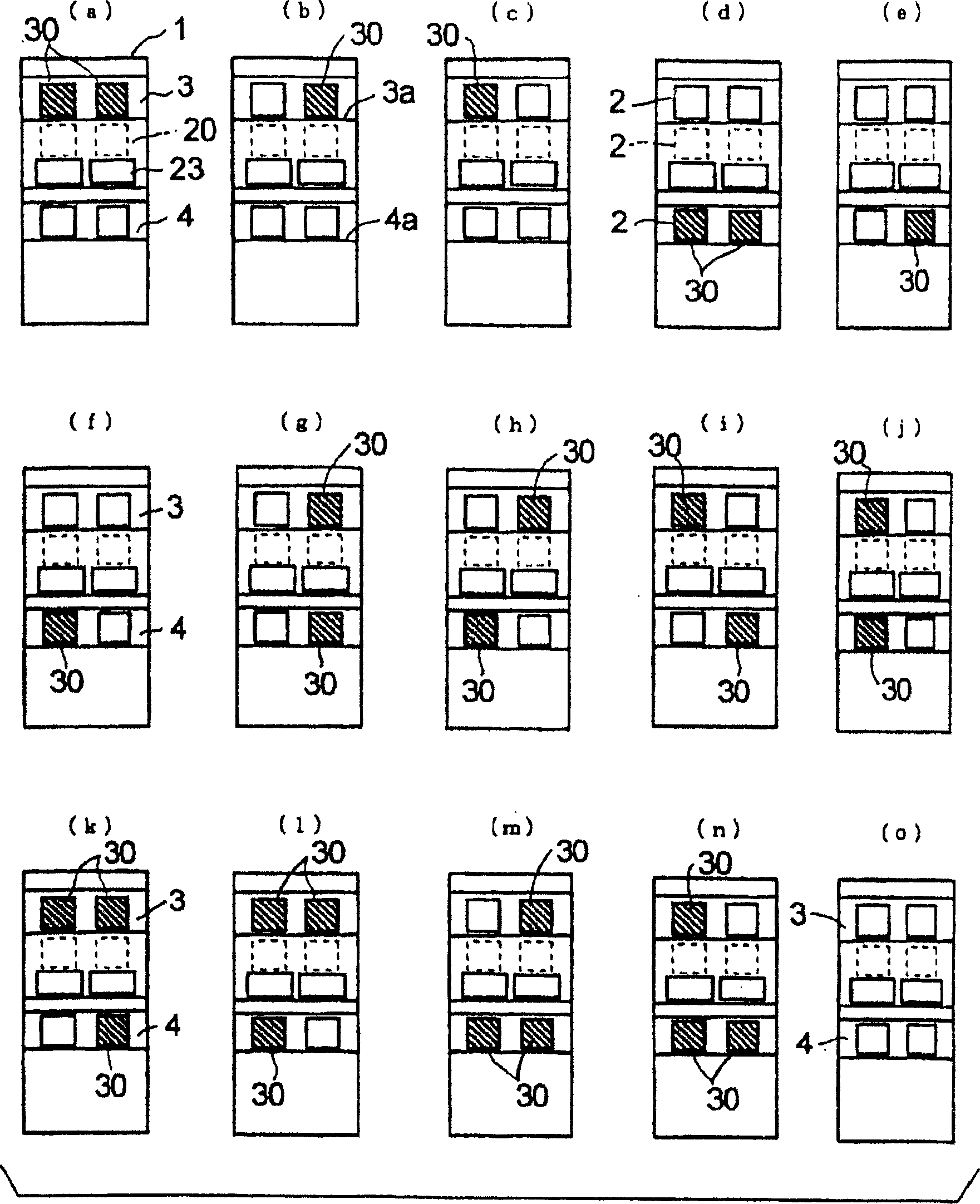

[0037] Hereinafter, best embodiments of the present invention will be described in detail with reference to the accompanying drawings. figure 1 It is a vertical cross-sectional view schematically showing a vertical heat treatment apparatus according to an embodiment of the present invention. figure 2 to represent figure 1 The perspective view of the schematic structure of the vertical heat treatment device shown in . image 3 It is an explanatory diagram showing how to use the vertical heat treatment apparatus.

[0038] In these figures, reference numeral 1 represents a vertical heat treatment apparatus, and this heat treatment apparatus 1 includes: a carrier (transport container) 2 for accommodating a plurality of pieces (for example, 25 pieces) of objects to be processed (for example, semiconductor wafers), through which Loading tables (carry-in and unloading parts) 3 and 4 that are carried into and out of the heat treatment device 1; as a first storage part that accommod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com