Multipoint synchronous lifting device and its lifting method

A technology of synchronous lifting and hydraulic lifting devices, which is applied in the direction of lifting devices, lifting frames, etc., can solve the problems of not being able to fully adapt to the requirements of high-precision multi-point synchronous lifting, and insufficient consideration of high-precision synchronous lowering, etc., to achieve friendly interface, solve performance and Inconsistent nominal value, high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

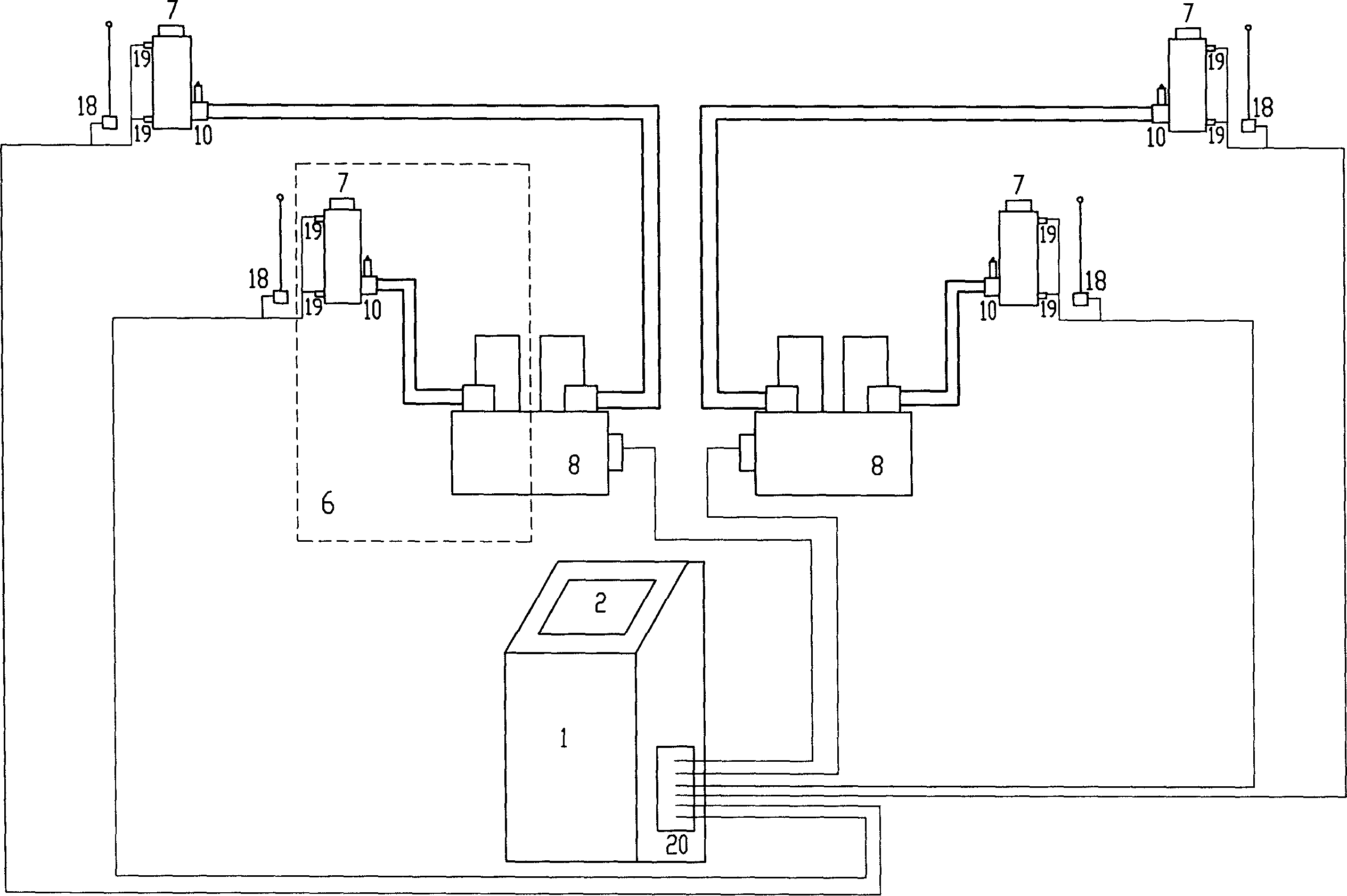

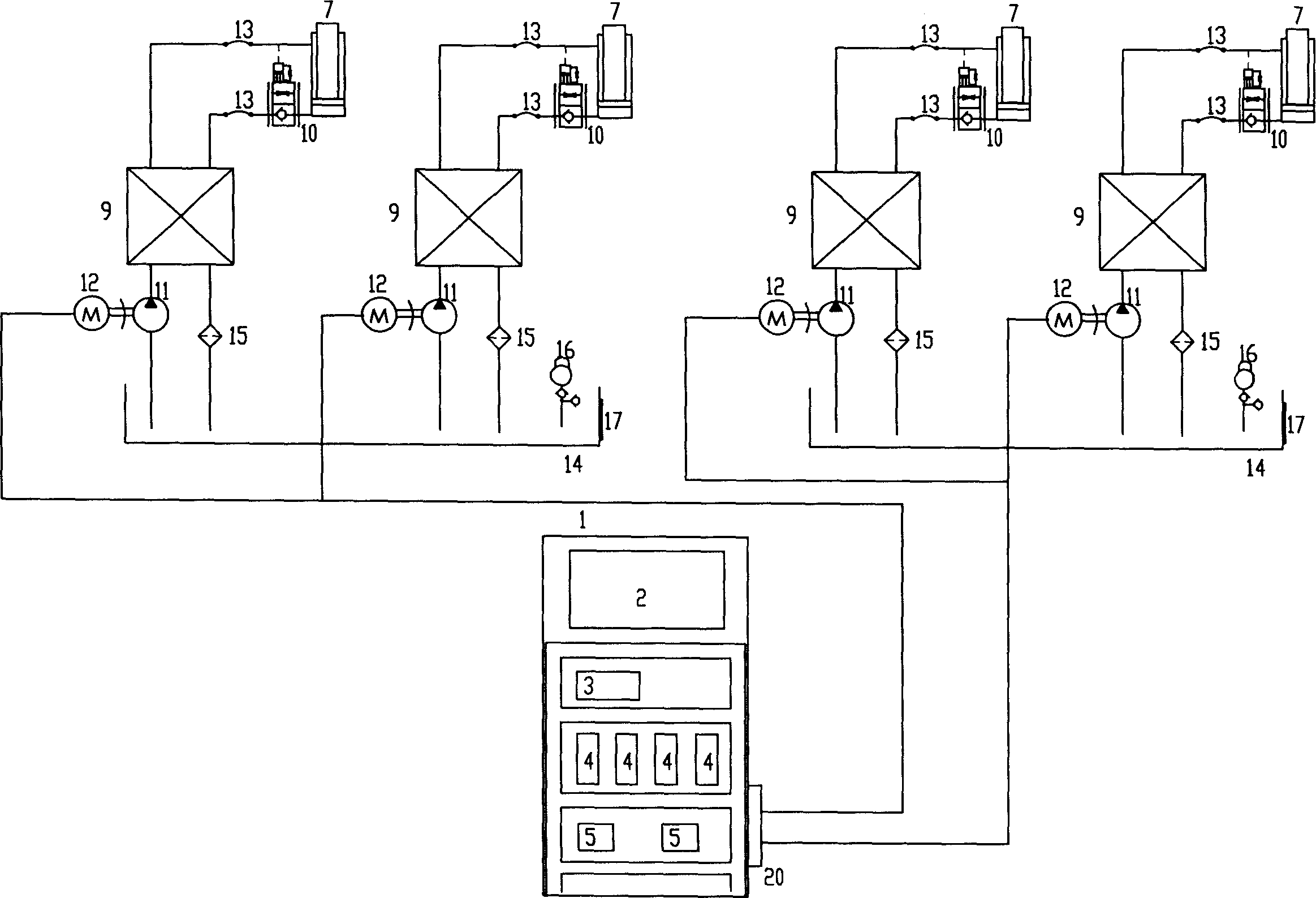

[0031] Below in conjunction with accompanying drawing and embodiment (large miter door lifting), the present invention is described in further detail, but the scope of implementation of the present invention, the mode are not limited thereto.

[0032] Refer to attached Figure 4 , this embodiment is four-point synchronization, and the large-scale miter gate of the Gezhouba ship lock is required to be lifted. The gate is 33.82 meters high, 19.7 meters wide, 2.7 meters thick, and the gate weighs 600 tons; the gate body is a flat beam structure with a panel on one side , The positions of the four jacking points have been limited, and the unbalanced load is serious. It is required to be lifted to a certain height in situ, and to fall back to the original position after the relevant parts are repaired, and the height difference of each point shall not be greater than 0.5mm.

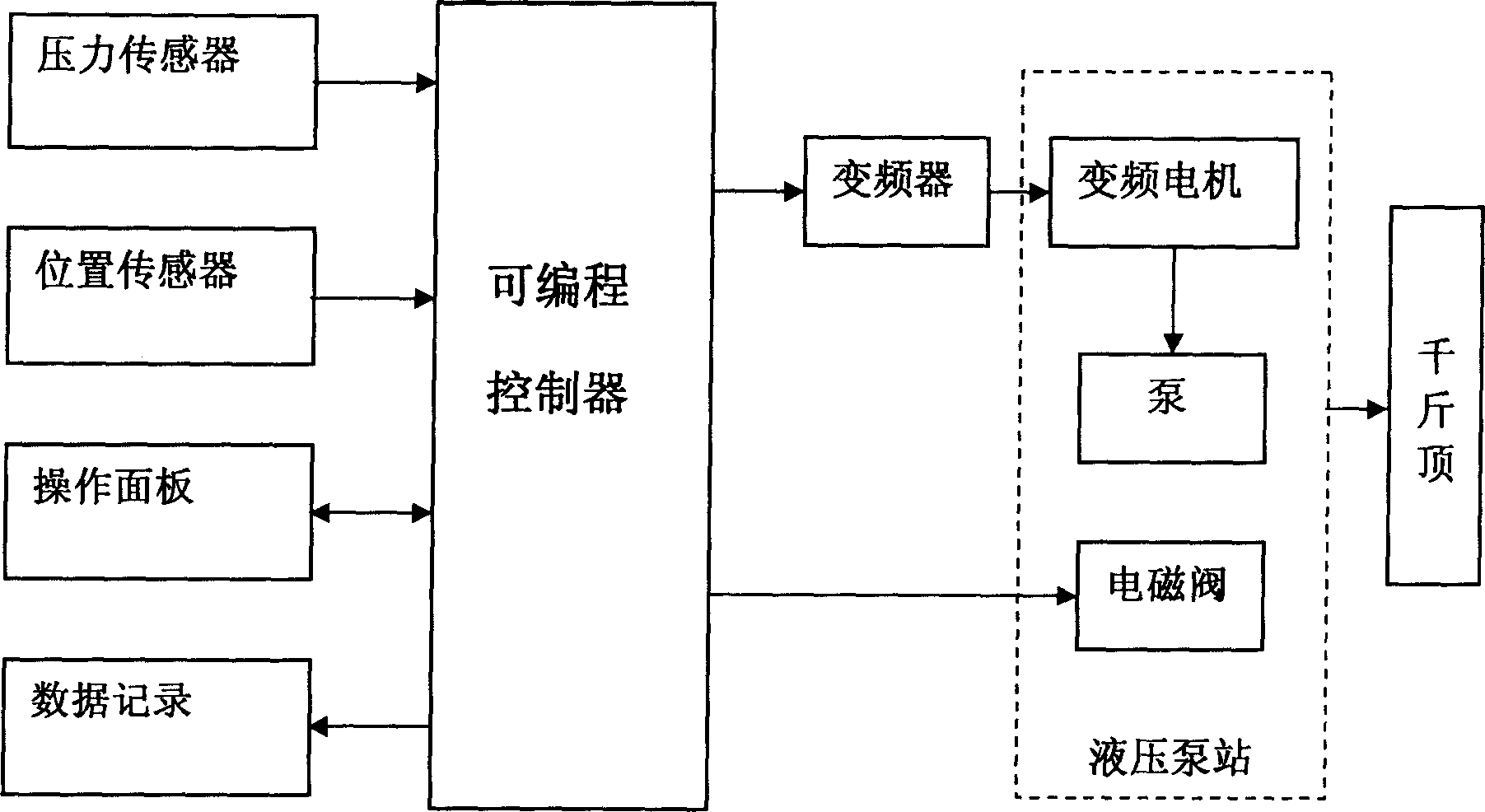

[0033] Refer to attached figure 1 , 2 , 3, a kind of multi-point synchronous lifting device of the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com