Installation with support means for driving an elevator car, and corresponding support means

A technology of bearing mechanism and equipment, applied in the field of bearing mechanism and elevator equipment, can solve the problems of large traction force and large friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

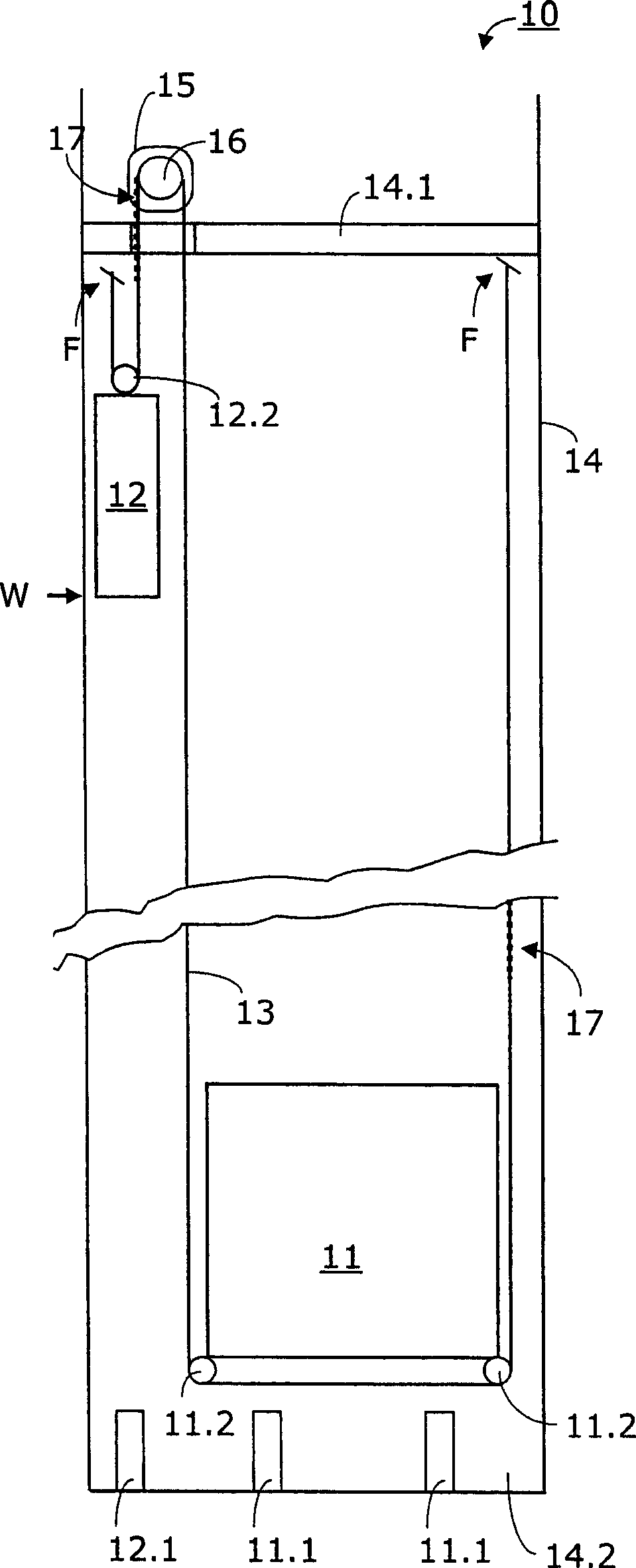

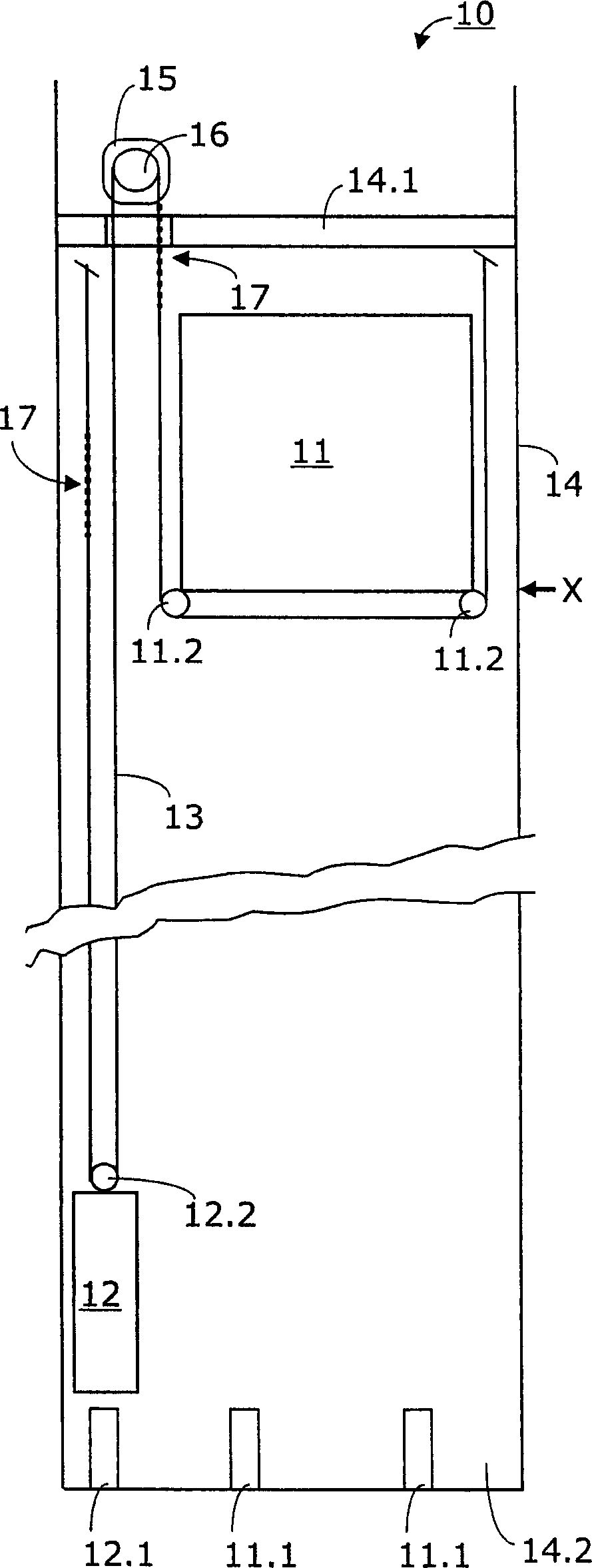

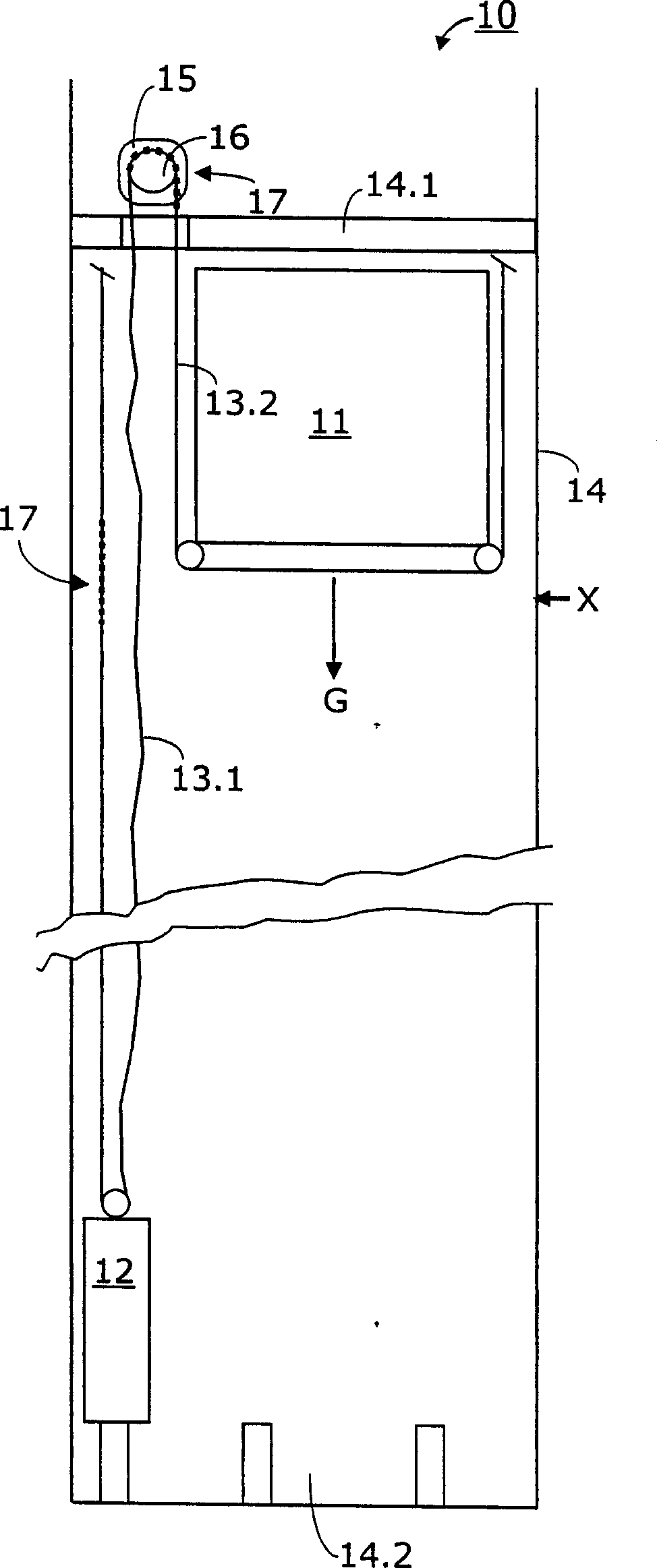

[0032] Figures 1A-1C A first embodiment of the present invention is shown in . exist Figures 1A-1C The exemplary embodiment shown in is a conventional elevator installation 10 comprising an elevator car 11 , which is surrounded, carried and moved by a support mechanism 13 from below. The supporting mechanism 13 is arranged such that its two free ends are fixed in the elevator shaft 14 or on the elevator shaft 14 . Let F represent a fixed point. Starting from a first fastening point F, the support means 13 extends downwards along the elevator shaft 14 . The carrier 13 then wraps around the elevator car 11 from below, which has rollers 11.2. The support means 13 extends upwards on the other side of the elevator car 11 and surrounds a drive wheel 16 which is driven, for example, by an electric motor 15 . Starting from the drive wheel 16 , the carrier runs downward again, wraps around the counterweight roller 12 .

[0033] In the exemplary embodiment shown, the shaft roof ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com