Hypoglycemic polypeptide from silkworm and its prepn and use

A technology of glycosidase inhibition and glucose, which is applied in the fields of chemistry and biology, can solve the problems of no hypoglycemic effect found and no elaboration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1A

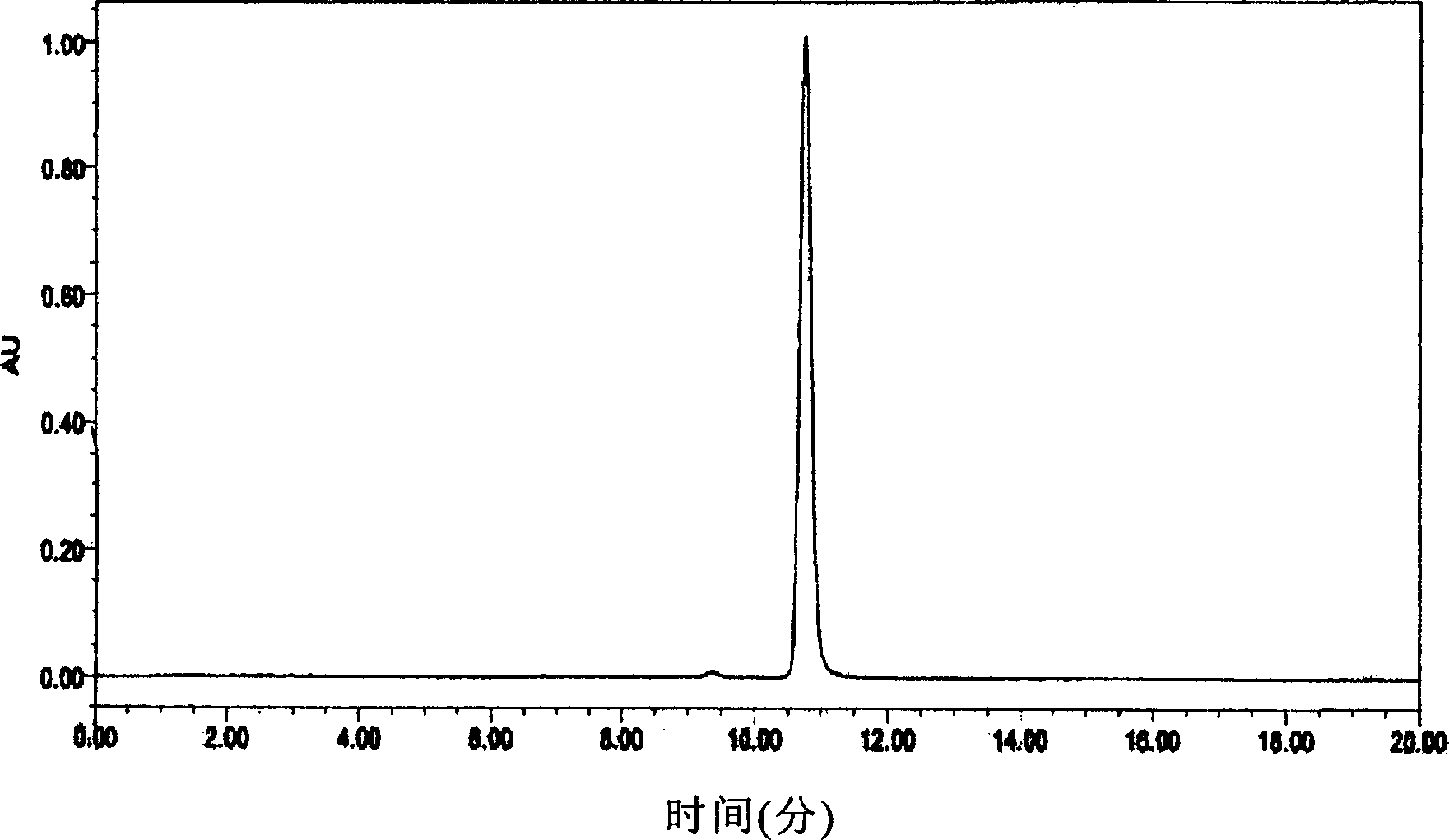

[0079] Preparation of Silkworm Hypoglycemic Polypeptide

[0080] Take 5 grams of fresh silkworm pupae and crush them at 4°C to homogenize, add 3 times the volume of sterile distilled water, stir at 4°C for 2 hours. After mixing thoroughly, centrifuge at 10000×g for 15 minutes to remove the precipitate, and take the supernatant for separation and purification.

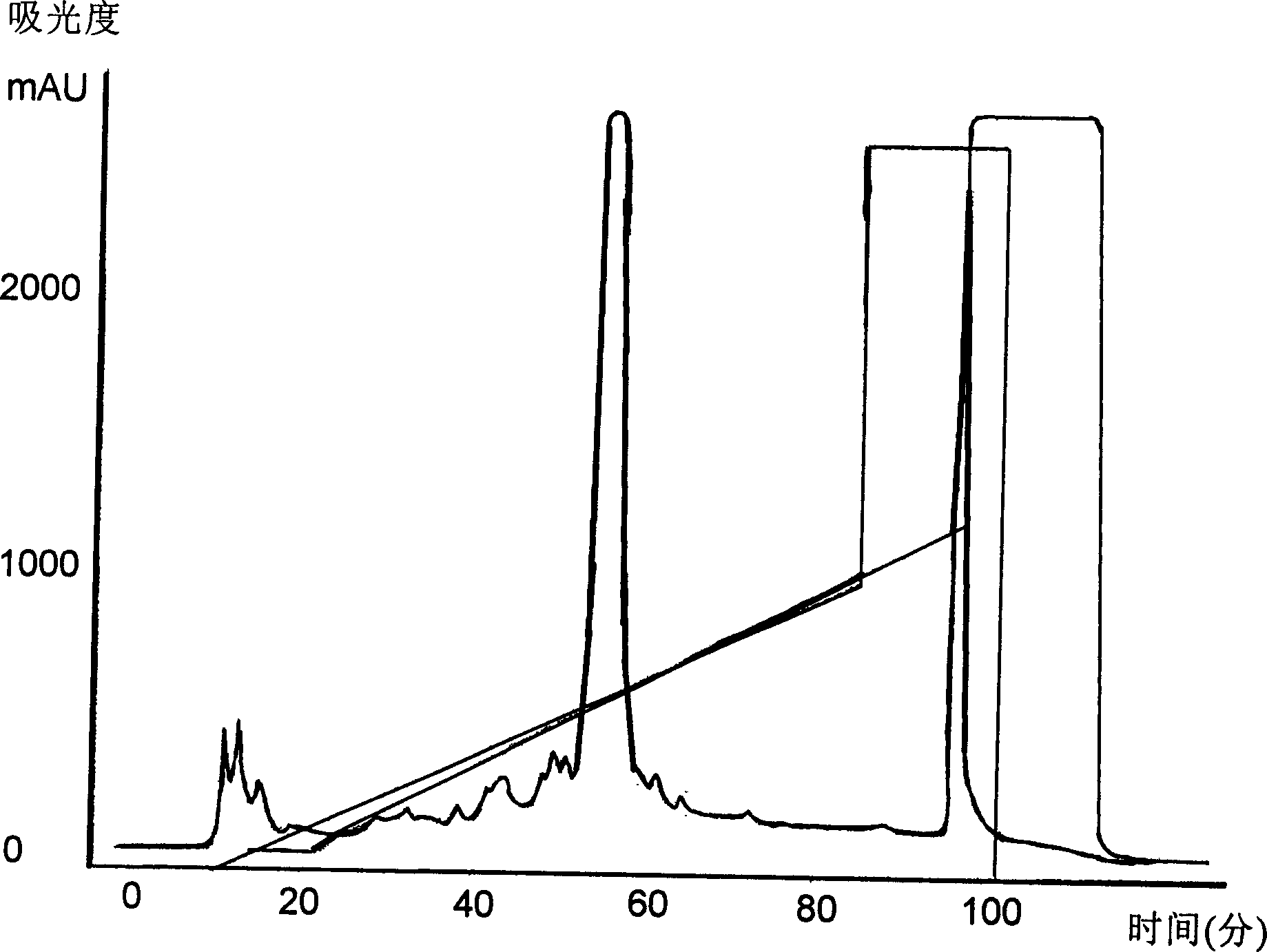

[0081] Take an appropriate amount of supernatant and apply it to the column for separation. The CM Sepharose FF filler produced by Pharmacia was used, and the buffer was a pH 5.8 HAc-NaAc system, and the linear gradient eluted to the buffer containing 1M NaCl. The specific separation and purification conditions are as follows:

[0082] 1. Column type: inner diameter 1.6cm, column height 20cm, column bed volume is 30ml.

[0083] 2. Packing: CM Sepharose FF, produced by Pharmacia.

[0084] 3. Sample loading: the supernatant after centrifugation.

[0085] 4. Column equilibration conditions: 20mM Tris buffer, pH 7.1, equilibrat...

Embodiment 1B

[0098]Preparation of Silkworm Hypoglycemic Polypeptide

[0099] Example 1A was repeated, but the difference was that 5 grams of fresh silkworm fifth instar larvae were used to replace the silkworm pupa in Example 1A.

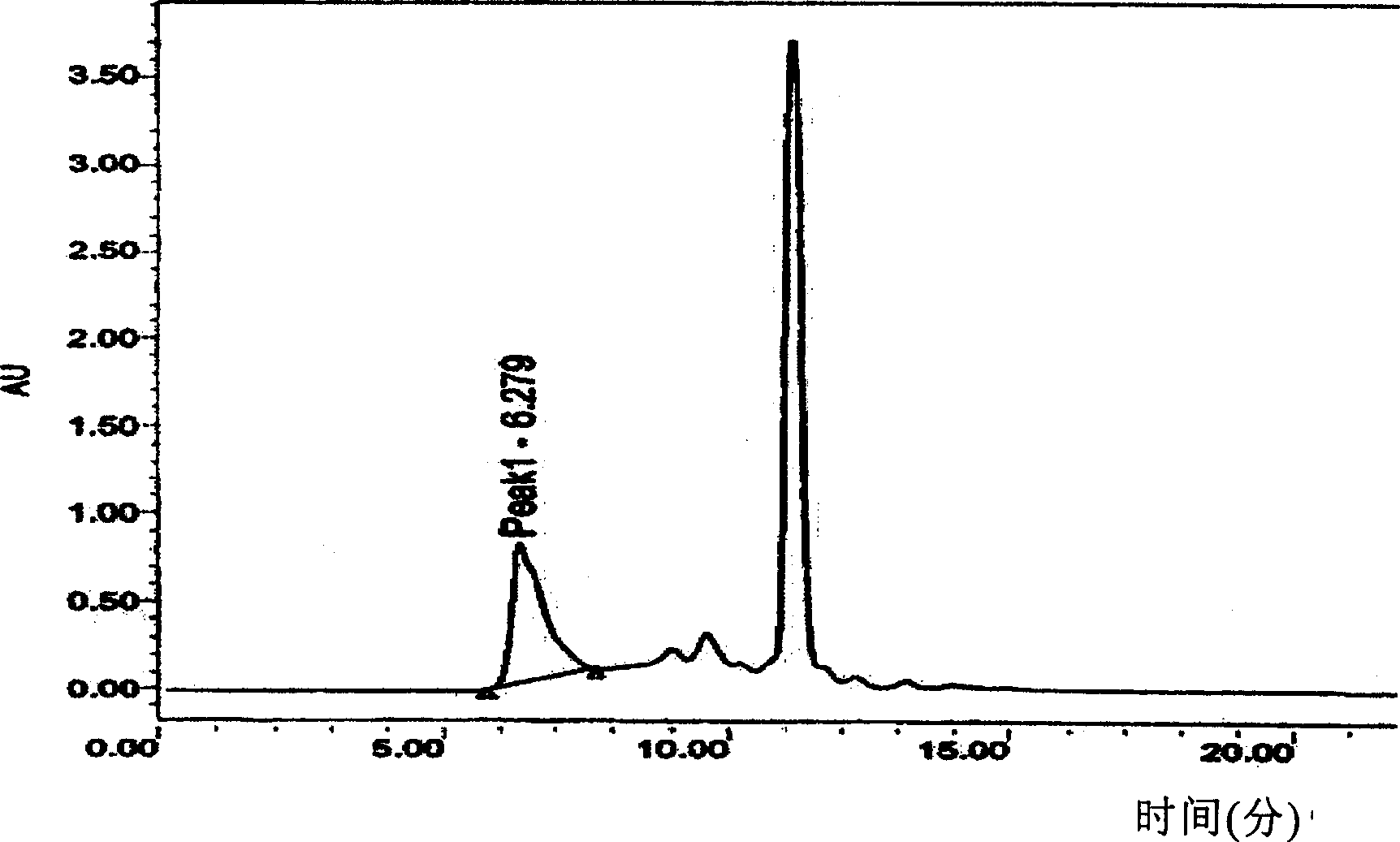

[0100] The result was basically the same as that of Example 1A, and there was a main peak of silkworm hypoglycemic polypeptide eluting at a concentration of 0.230-0.255M NaCl. The amount of the prepared silkworm hypoglycemic polypeptide is 0.298 g, which is about 80-90% of that in Example 1A.

Embodiment 1C

[0102] Preparation of Silkworm Hypoglycemic Polypeptide

[0103] Repeat Example 1A, the difference is that 1 gram of freeze-dried silkworm powder from the fifth-instar larva of the silkworm was used to replace the silkworm pupae in Example 1A. The freeze-dried silkworm powder was first dissolved in 3 kg of sterile distilled water and stirred at 4°C. 2 hours. After mixing thoroughly, centrifuge at 10000×g for 15 minutes to remove the precipitate, and take the supernatant for separation and purification.

[0104] The result was basically the same as that of Example 1A, and there was a main peak of silkworm hypoglycemic polypeptide eluting at 0.230-0.255M NaCl concentration. The amount of the prepared silkworm hypoglycemic polypeptide was 0.375 grams.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com