Cover board bar of carding engine cylinder and leveling gum adding method

A technology of movable cover and carding machine, used in deburring devices, textiles and papermaking, fiber processing, etc., can solve the problems of difficult to meet requirements, large gap fluctuations, affecting carding quality, etc., and improve carding quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

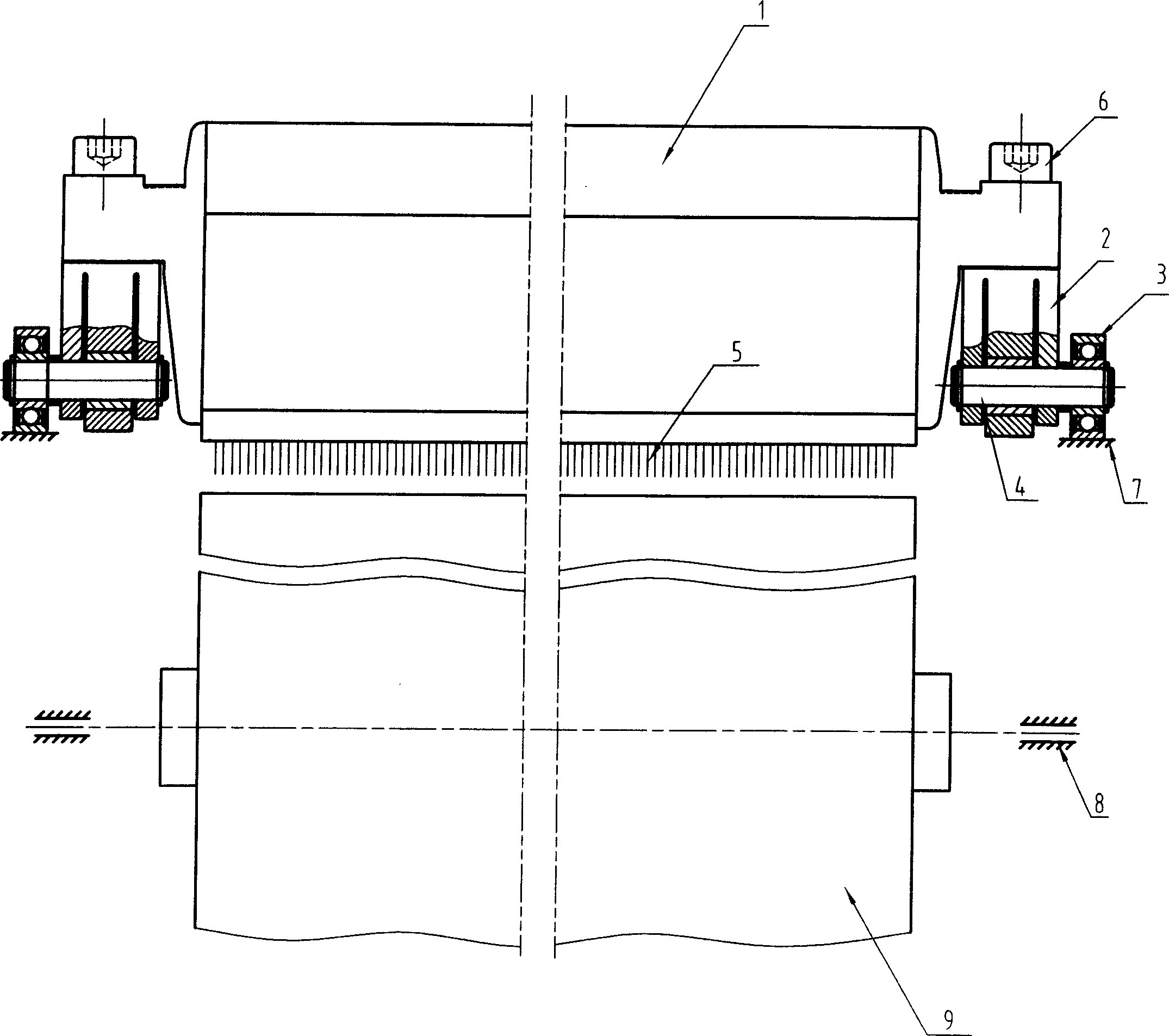

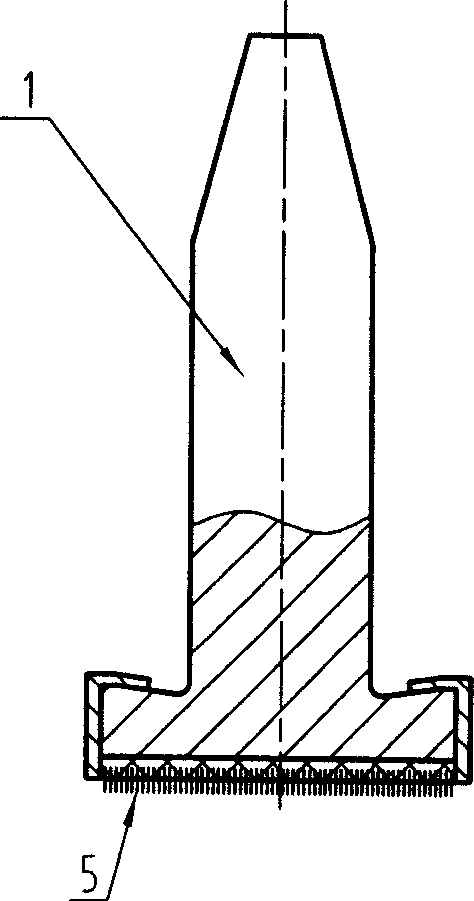

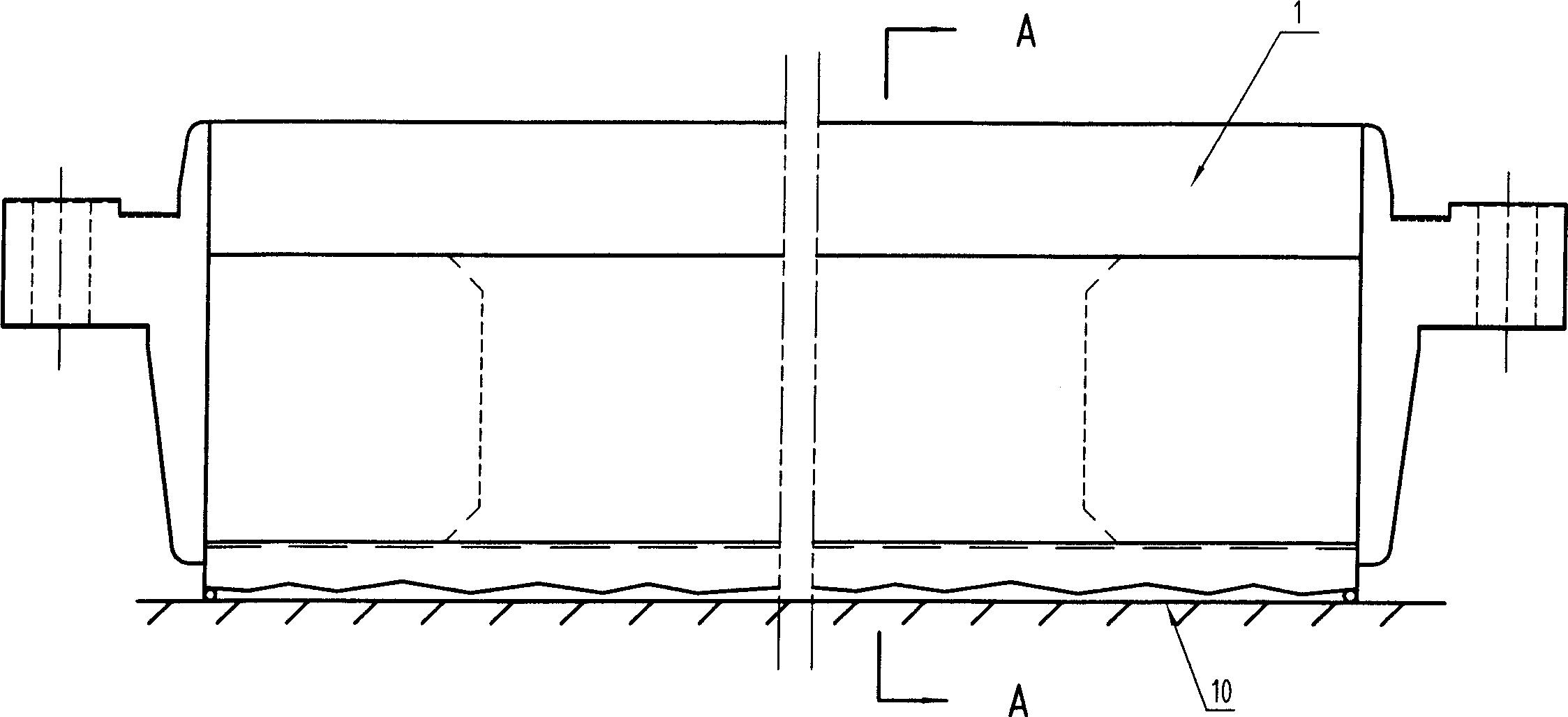

[0022] Embodiment 1: The carding machine cylinder cover slats of the present invention include a T-shaped strip 11 and a bottom plane 12, which is characterized in that: the bottom plane 12 is provided with a strengthening adhesion structure 14 of a dovetail groove, which is flat The adhesive layer 13 is firmly pasted on the bottom plane 12, and the strengthened adhesion structure 14 of the dovetail groove is longitudinally distributed on the bottom plane 12 of the cover strip, that is, distributed along the length direction of the bottom plane 12.

[0023] In this example, the cross-sectional shape of the strengthening adhesion structure 14 can also be T-shaped groove, rectangular groove, or their combination. The strengthening adhesion structure 14 can be distributed laterally, obliquely, or reticularly on the bottom plane of the cover strip.

Embodiment 2

[0024] Embodiment 2: the novel cover strip of carding machine described in the present invention, comprises T-shaped strip body 11 and bottom plane 12, it is characterized in that: offer several regular holes at the bottom plane 12 of cover strip, flat glue layer 13 Stick firmly on the bottom plane 12.

[0025] The method of adding leveling rubber for the movable cover plate of the above-mentioned carding machine cylinder is as follows:

[0026] ①The cover strip is drawn according to the existing drawing method, and the adhesion thickness of the smooth adhesive layer 13 is reserved on the bottom plane of the cover strip, which is generally controlled at 0.15 mm to 1.5 mm. For the bonding fastness between the planes 12, a reinforced adhesive structure 14 with a depth of 0.2 mm to 1.5 mm is processed on the bottom plane 12 of the cover strip. The cross-sectional shape of the reinforced adhesive structure 14 is preferably dovetail, T-shaped, rectangular or their combination. and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com