Civil engineering materials curing agent and preparation method thereof

A curing agent and civil engineering technology, applied in the field of civil engineering material curing agent and preparation, can solve the problems of poor frost resistance, low strength, high cost, etc., and achieve good frost resistance, high consolidation strength, high durability and suitable Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

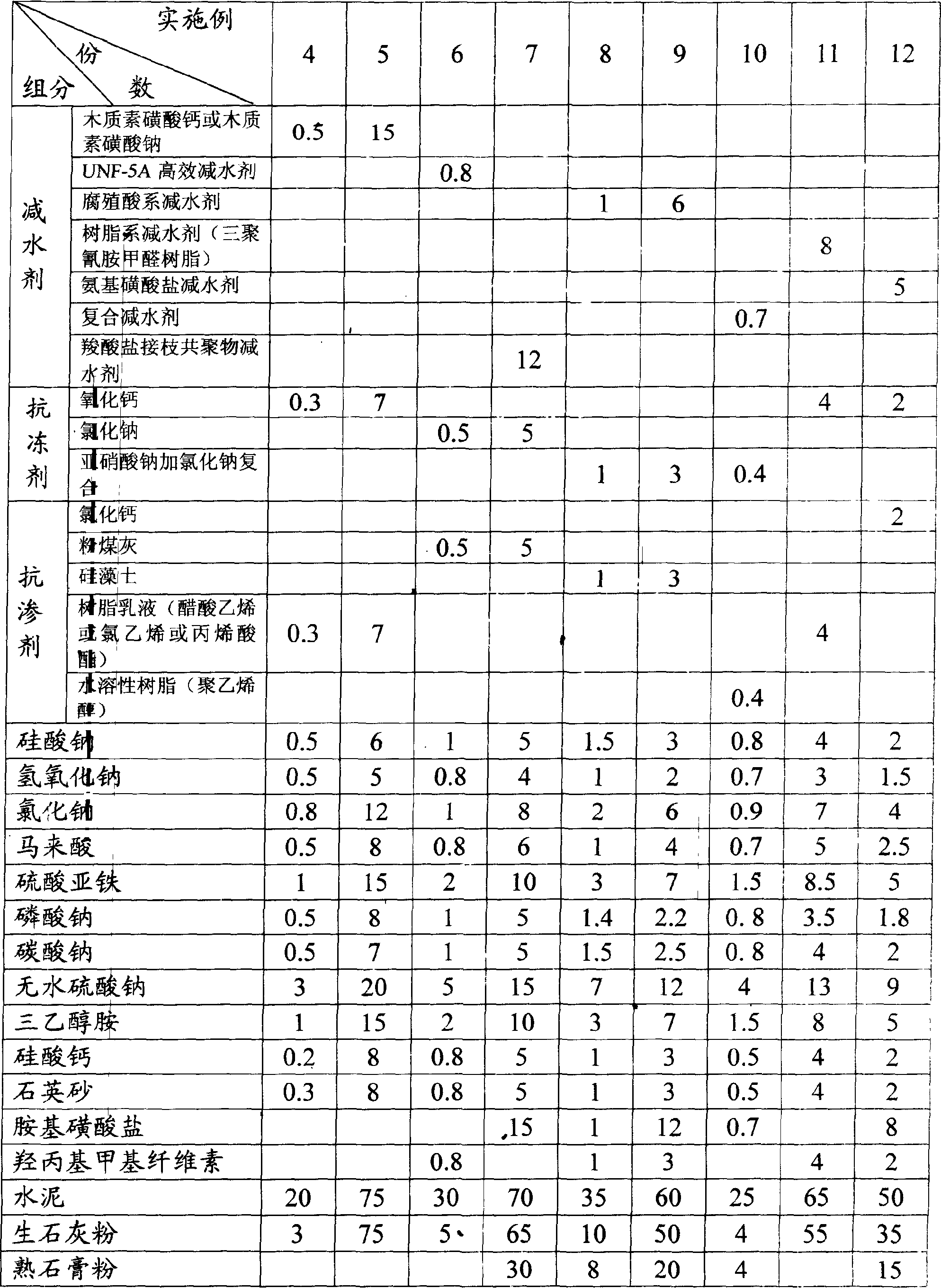

[0042] The solidifying agent for civil construction materials of the present invention is formulated from materials containing the following components:

[0043] 0.5-15 parts of water reducing agent, 0.3-7 parts of antifreeze agent, 0.3-7 parts of anti-seepage agent, 0.5-6 parts of sodium silicate, 0.5-5 parts of sodium hydroxide, 1-12 parts of sodium chloride, 0.5-8 parts of acid, 1-15 parts of ferrous sulfate, 0.5-8 parts of sodium phosphate, 0.5-7 parts of sodium carbonate, 3-20 parts of anhydrous sodium sulfate, 1-15 parts of triethanolamine, 0.2-8 parts of calcium silicate 0.3-8 parts of quartz sand, 20-75 parts of cement and 3-75 parts of quicklime powder;

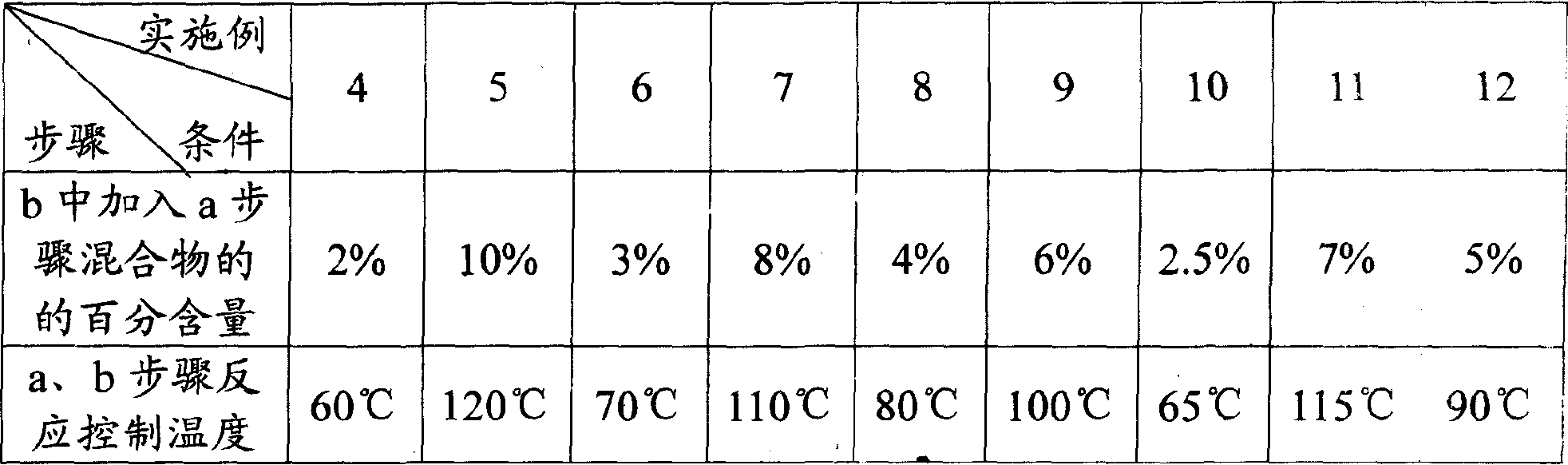

[0044] Its specific preparation method is: a. 0.5-15 parts of water reducing agent, 0.3-7 parts of antifreeze agent, 0.3-7 parts of anti-seepage agent, 0.5-6 parts of sodium silicate, 0.5-5 parts of sodium hydroxide, 1-12 parts of sodium chloride, 0.5-8 parts of maleic acid, 1-15 parts of ferrous sulfate, 0.5-8 part...

Embodiment 2

[0047] The solidifying agent for civil engineering materials of the present invention is realized by the following preparation methods:

[0048] a. Add 0.8 to 12 parts of water reducing agent, 0.5 to 5 parts of antifreeze agent, 0.5 to 5 parts of impervious agent, 1 to 5 parts of sodium silicate, 0.8 to 4 parts of sodium hydroxide, and 1 to 8 parts of sodium chloride , 0.8-6 parts of maleic acid, 2-10 parts of ferrous sulfate, 1-5 parts of sodium phosphate, 1-5 parts of sodium carbonate, 5-15 parts of anhydrous sodium sulfate, 2-10 parts of triethanolamine, calcium silicate 0.8-5 parts and 0.8-5 parts of quartz sand are added to the ball mill for grinding, the temperature is controlled at 70-110°C, the grinding fineness reaches 290-400 mesh, the color is slightly yellow, and it is packed in bags for later use;

[0049] b. Then add 30-70 parts of cement, 8-65 parts of quicklime powder and 3-8% of the mixture obtained in step a into the ball mill for grinding at the same time. T...

Embodiment 3

[0051] The solidifying agent for civil construction materials of the present invention is composed of the following components: 1-6 parts of water reducing agent, 1-3 parts of antifreeze agent, 1-3 parts of anti-seepage agent, 1.5-3 parts of sodium silicate, 1 part of sodium hydroxide ~2 parts, 2~6 parts of sodium chloride, 1~4 parts of maleic acid, 1~12 parts of sulfamate, 3~7 parts of ferrous sulfate, 1.4~2.2 parts of sodium phosphate, 1.5~2.5 parts of sodium carbonate 7-12 parts of anhydrous sodium sulfate, 3-7 parts of triethanolamine, 1-3 parts of calcium silicate, 1-3 parts of hydroxypropyl methylcellulose, 1-3 parts of stone sand, 35-60 parts of cement 10-50 parts of quicklime powder and 8-20 parts of plaster powder. The specific preparation method is:

[0052] a. Add the above-mentioned parts of water reducing agent, antifreeze agent, anti-seepage agent, sodium silicate, sodium hydroxide, sodium chloride, maleic acid, sulfamate, ferrous sulfate, sodium phosphate, sodiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com