Device for supporting plastic section material

A technology for supporting devices and plastic profiles is applied in the field of devices supporting plastic profiles, especially plastic pipes, and can solve the problems of increasing inventory requirements and equipment time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

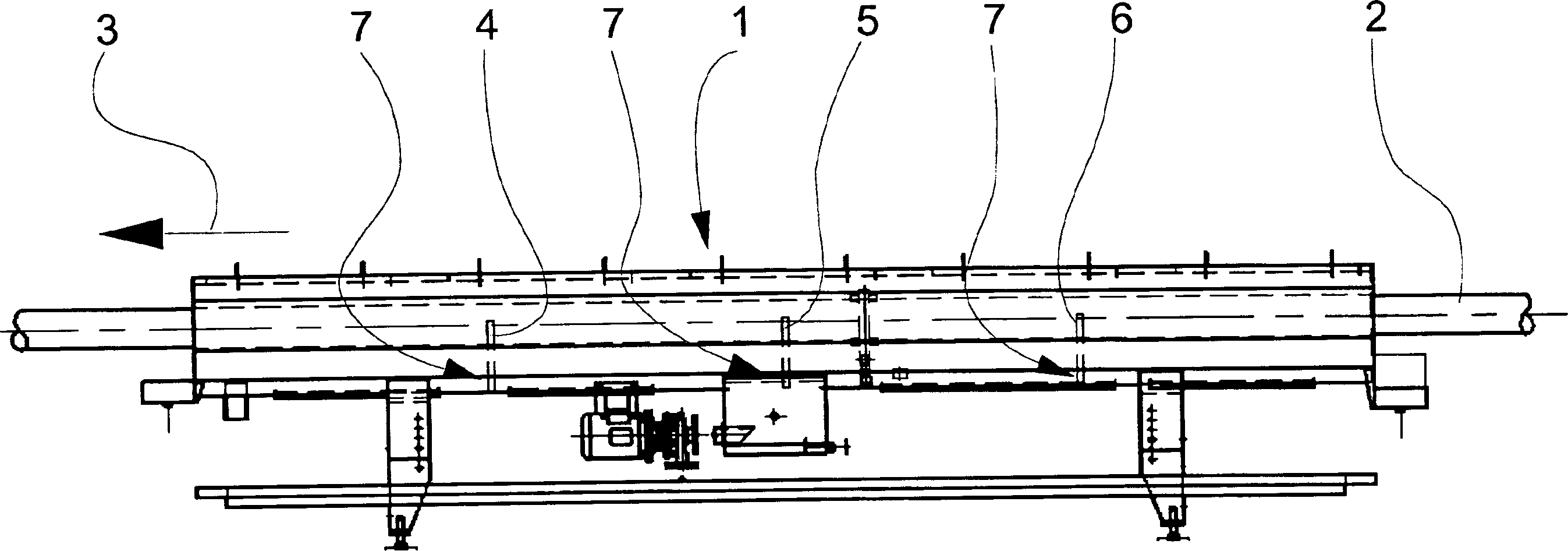

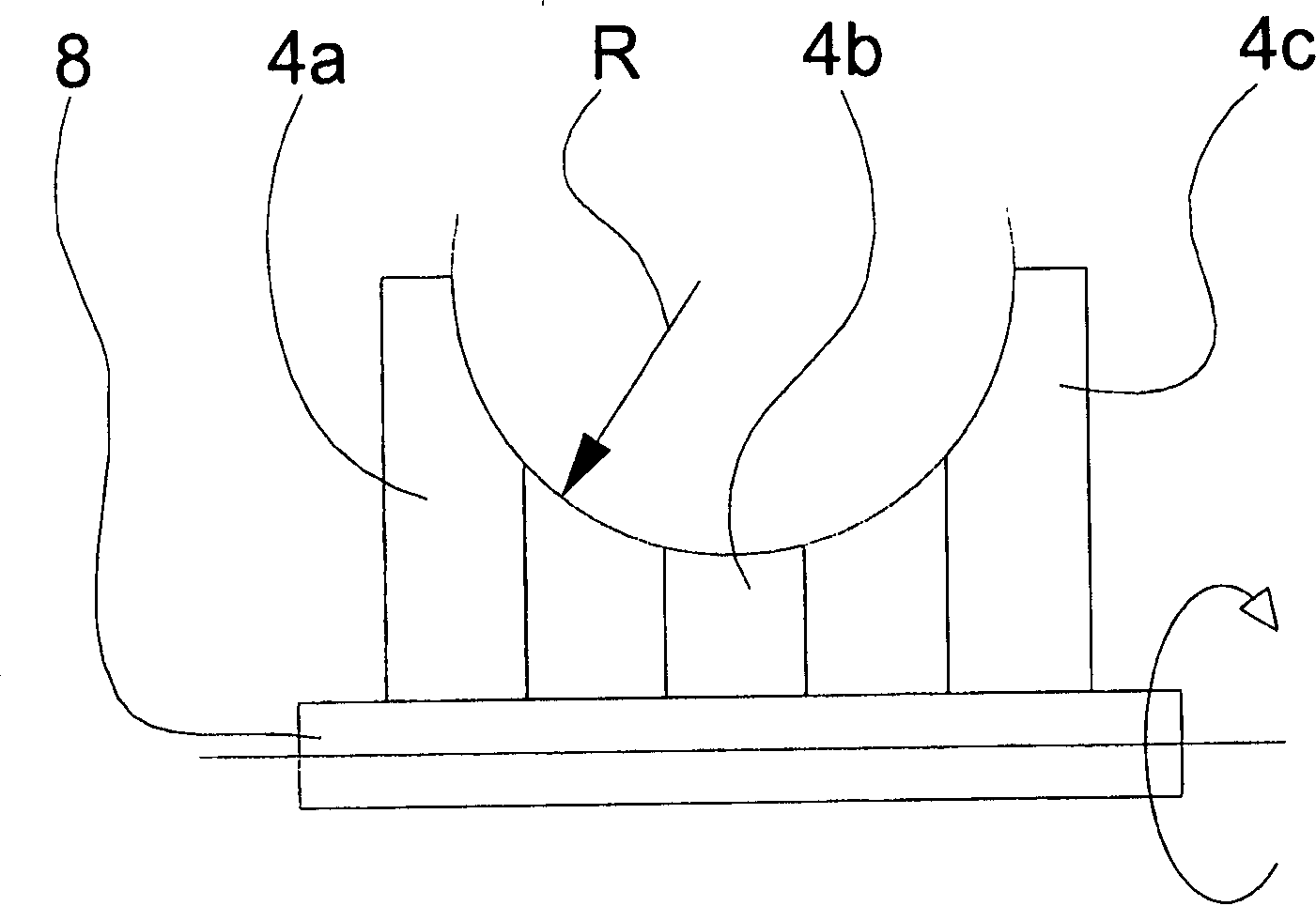

[0019] figure 1 Shown is a calibrating and / or cooling device 1 , a plastic pipe 2 leading there, and three support sheets 4 , 5 and 6 . Each of the supporting lamellae 4 , 5 and 6 is equipped with its own operating device 7 , by means of which these lamellae can be rotated individually counter to the extrusion direction 3 . Each of the sheets 4, 5, 6 has a different radius R. Advantageously, the radius R increases or decreases along the sheets 4, 5, 6, thereby achieving that when the sheet with the smaller radius is used to support the tube, the corresponding sheet with the larger radius does not have to be forced to disengage .

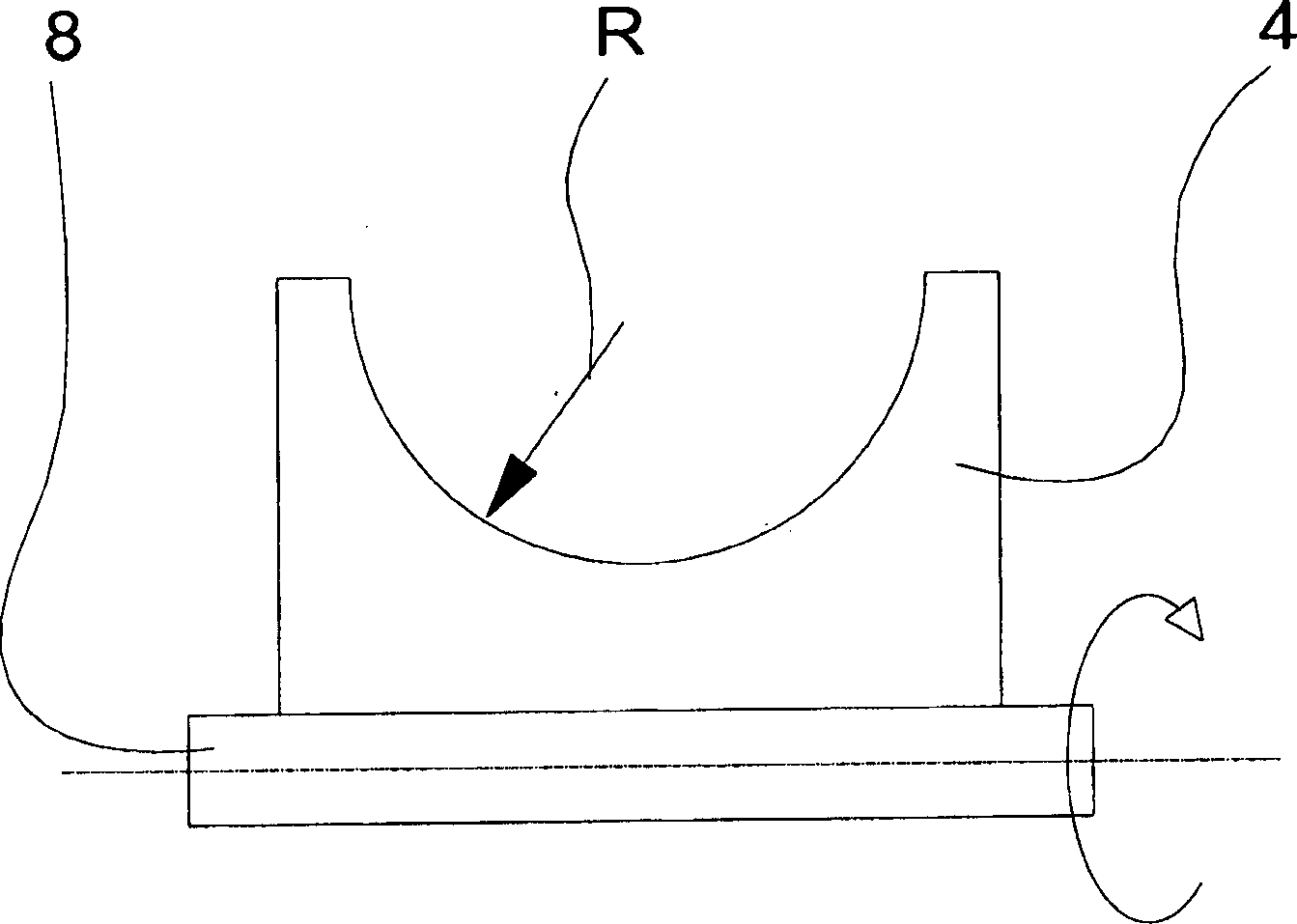

[0020] One of the sheets 4, 5 or 6 is schematically in figure 2 shown in . The supporting sheet has a radius R which is approximately semicircular, wherein the arc of the circle should not be greater than 180° in order to prevent the sheet from jamming the extrudate. Each lamella has its own axis of rotation 8 , about which the lamella can be t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com