Spring wire processing device

A processing device and spring wire technology, applied in the direction of extensible conductors, extensible conductor cables, manufacturing extensible conductors/cables, etc. problem, to ensure the quality of the line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Through the applicant's description of the embodiments below, it will be more helpful to understand the technical essence of the present invention and make the effect of the present invention more manifest, but the embodiments should not be regarded as any limitation to the present invention.

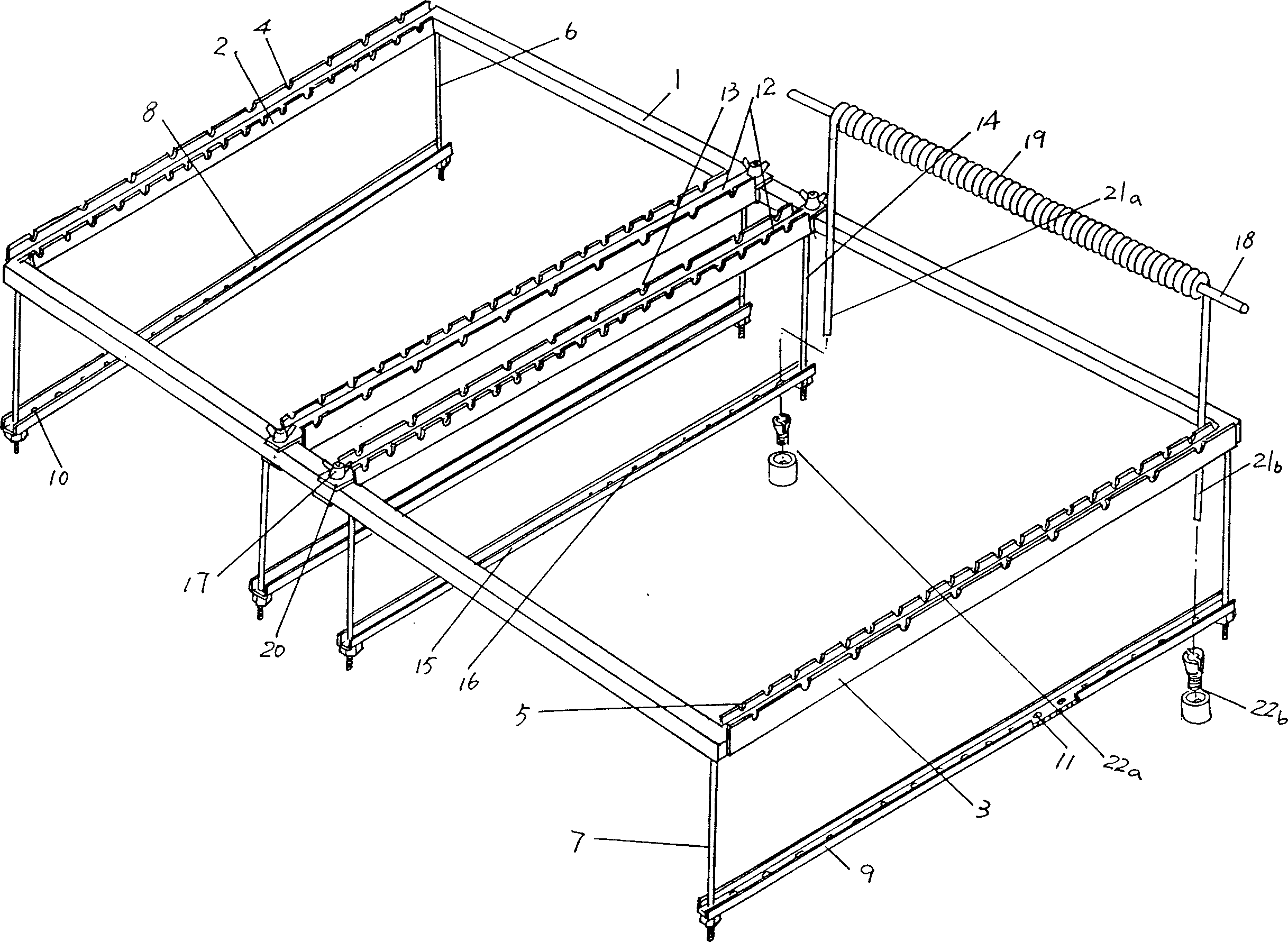

[0020] exist figure 1 In, the applicant provides a bracket 1 which is rectangular, more specifically rectangular, and which is made of stainless steel. The two ends of the bracket 1 are respectively formed with first and second winding rod positioning plates 2 and 3. As shown in the figure, the first and second winding rod positioning plates 2 and 3 adopt a composite structure. The so-called composite structure refers to the first 1. The second rod-winding positioning plate 2,3 is processed into a cross-sectional shape that is U-shaped or horseshoe-shaped, so that the first and second winding rod positioning plates 2,3 each have a pair of wall bodies, and on each wall body The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com