Silicone composition and polymer dispersed liquid crystal

A technology of composition and siloxane, which is applied in the direction of liquid crystal materials, chemical instruments and methods, and can solve problems such as unavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

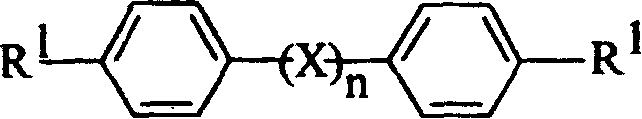

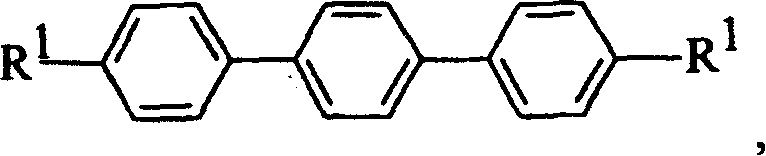

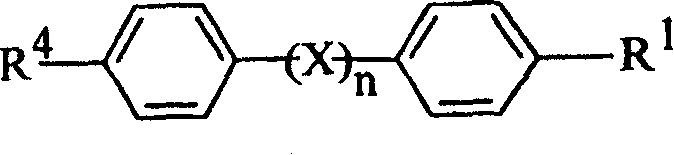

[0091] A curable silicone composition was prepared by thoroughly mixing the following components in an amber bottle: 24.23 g consisting essentially of 70 mol% PhMeSiO 2 / 2 unit, 27mol% Me 2 SiO 2 / 2 unit and 3mol% Me 2 ViSiO 1 / 2 A dimethylvinylsiloxy-terminated organopolysiloxane composed of units, wherein the organopolysiloxane has a number average molecular weight of 6,161 and a weight average molecular weight of 11,320; 1.002 g has the chemical formula CH 3 CH 2 C(CH 2 CO 2 CH 2 CH 2 SH) 3 and 0.218 g of Darocur 4265 (BASF Corporation), a compound consisting of 50% 2-hydroxy-2-methyl-1-phenyl-propan-1-one and 50% 2,4,6-tris Photoinitiator composed of tolyldiphenylphosphine oxide. The silicone composition (0.409 g) was combined with 0.055 g of Dow Corning 705 Fluid, a mixture of 90% trimethylpentaphenyltrisiloxane and 10% tetramethylhexaphenyltetrasiloxane and 0.111 g of liquid crystal E7 (MerckNB-SC, UK), a mixture of 51% 4-pentyl-4'-cyanobiphenyl, 25% 4-heptyl-4'-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com