Automatic engine halt system

An engine stop and engine technology, applied in engine components, engine control, engine starting, etc., can solve the problems of restart, reduce the service life of centrifugal clutch, instability, etc., and achieve the effect of small wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

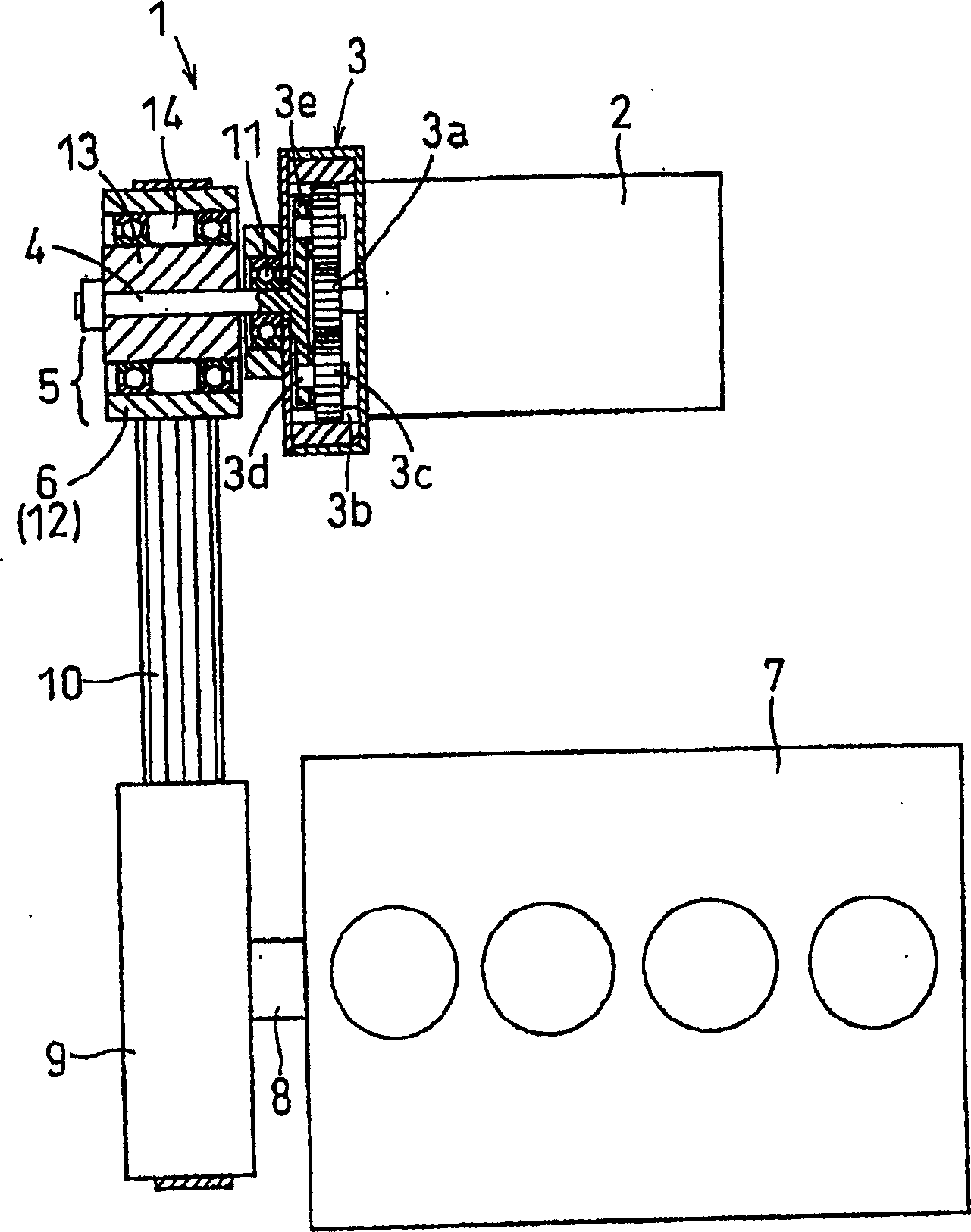

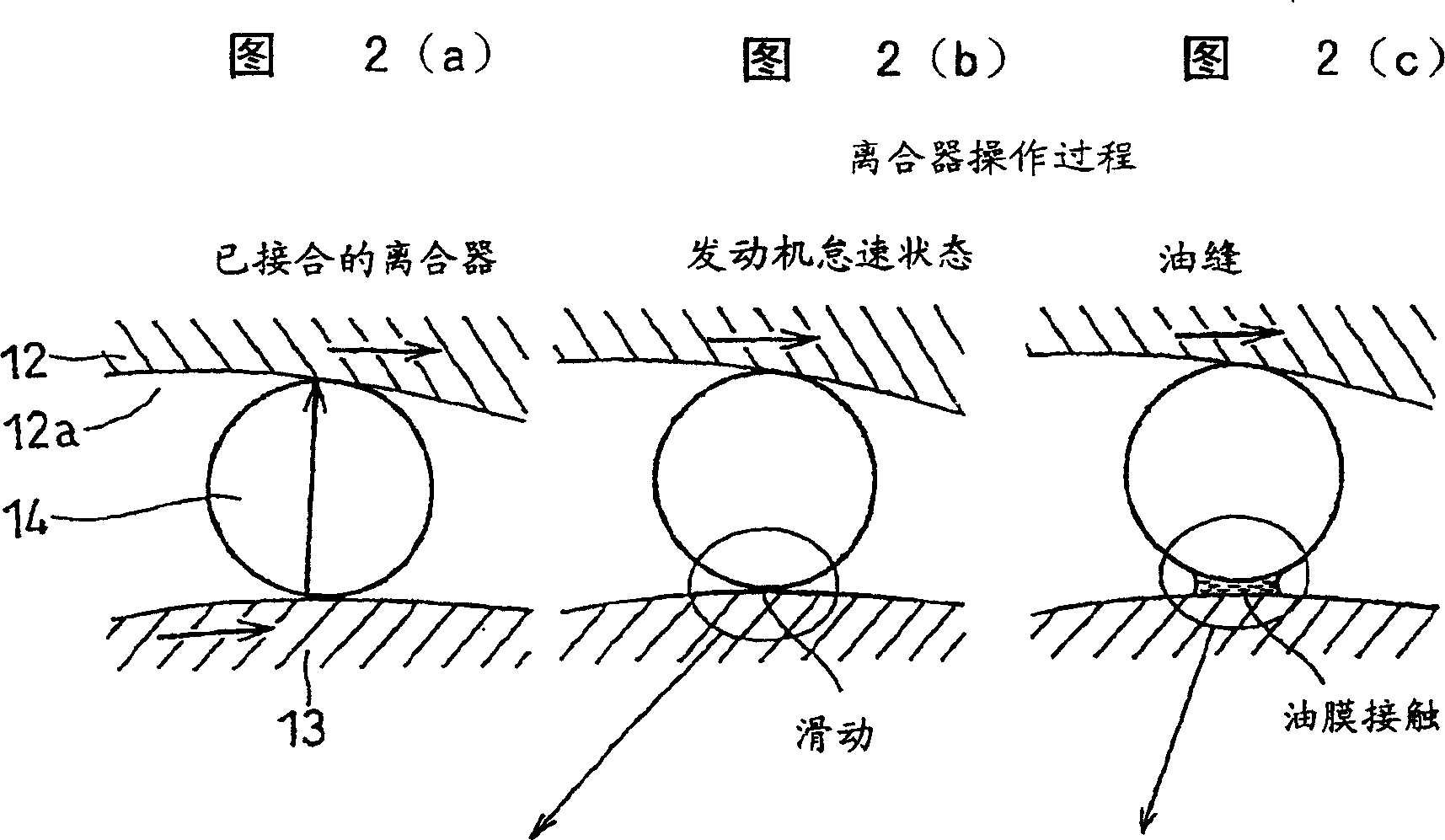

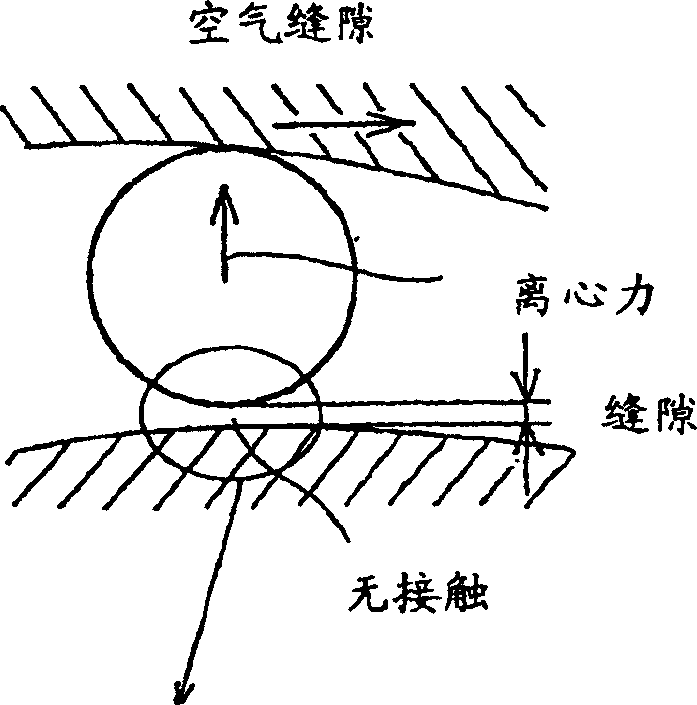

[0027] Referring to the drawings, like reference numerals denote like parts throughout the several views, in particular figure 1 An engine starter 1 as an example of a first embodiment of the present invention, which will be described below, is shown, which is commonly used to start an internal combustion engine of a motor vehicle.

[0028] Engine starter 1 mainly comprises electric motor 2 (also refers to starter motor below), speed reducer 3, output shaft 4, the centrifugal clutch 5 that is connected with output shaft 4 and starter pulley 6. The speed reducer 3 is used to reduce the speed of the starter motor 2 . The output shaft 4 transmits the torque output by the reducer to the starter pulley 6 through the centrifugal clutch 5 . The starter pulley 6 is connected with the crankshaft pulley 9 through a belt 10 . The crank pulley 9 is connected to the crankshaft 8 of the engine 7 .

[0029] The starter motor 2 is implemented by energizing an armature installed in a known ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com