Mechanical device for removing gear-hobbing burr

A mechanical device and burr technology, applied in the direction of mechanical equipment, components with teeth, gear teeth, etc., can solve the problem of difficult to remove burrs, and reduce the process of deburring by fitters or end faces of lathes, reducing production. cost, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

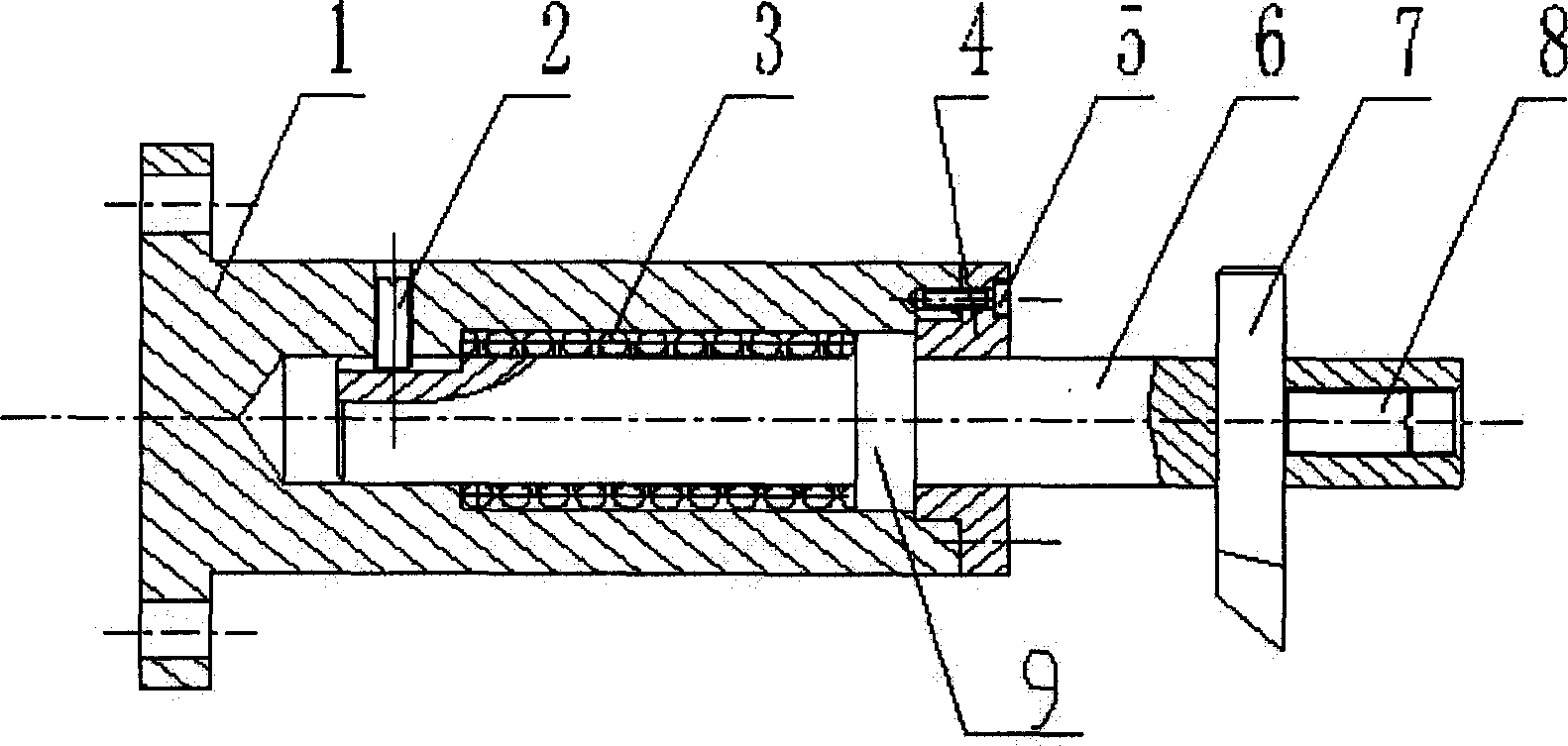

[0024] The embodiment of the present invention: make the base 1, the spring 3, the flange 4, the sliding rod 6, the burr 7 and other parts, according to figure 1 Assemble as shown. First, put the spring 3 on the sliding rod 6 and insert it into the base 1. The two ends of the spring 3 rest on the shoulder 9 and the inner hole step of the base 1, and screw the anti-rotation screw 2 into the base 1. Tighten it in the groove of the sliding rod 6; then, connect the flange 4 with the base 1 with the connecting screw 5; finally, insert the deburring knife 7 into the square hole of the sliding rod 6, and adjust the extension of the deburring knife 7. Use the compression screw 8 to fix the length.

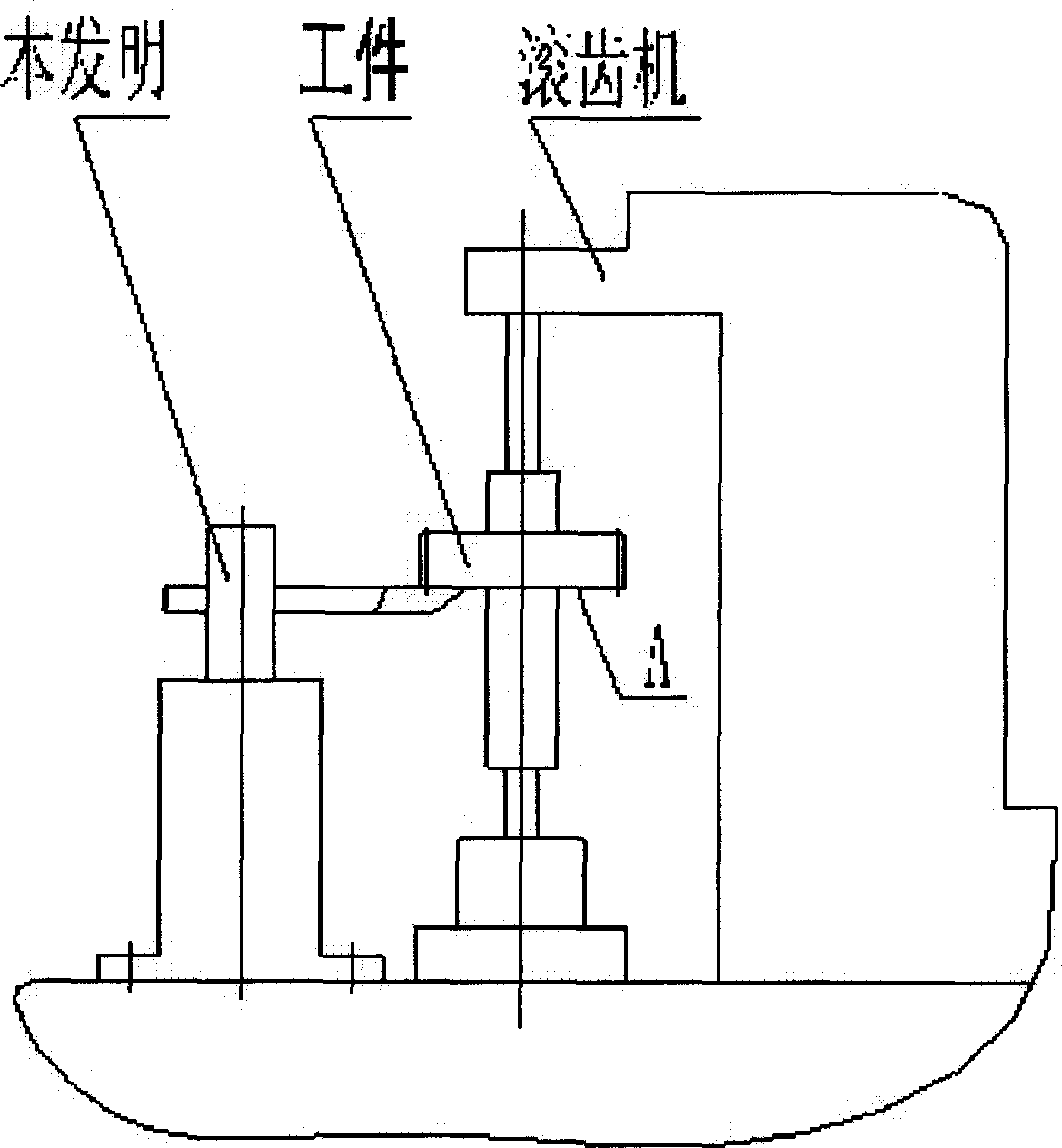

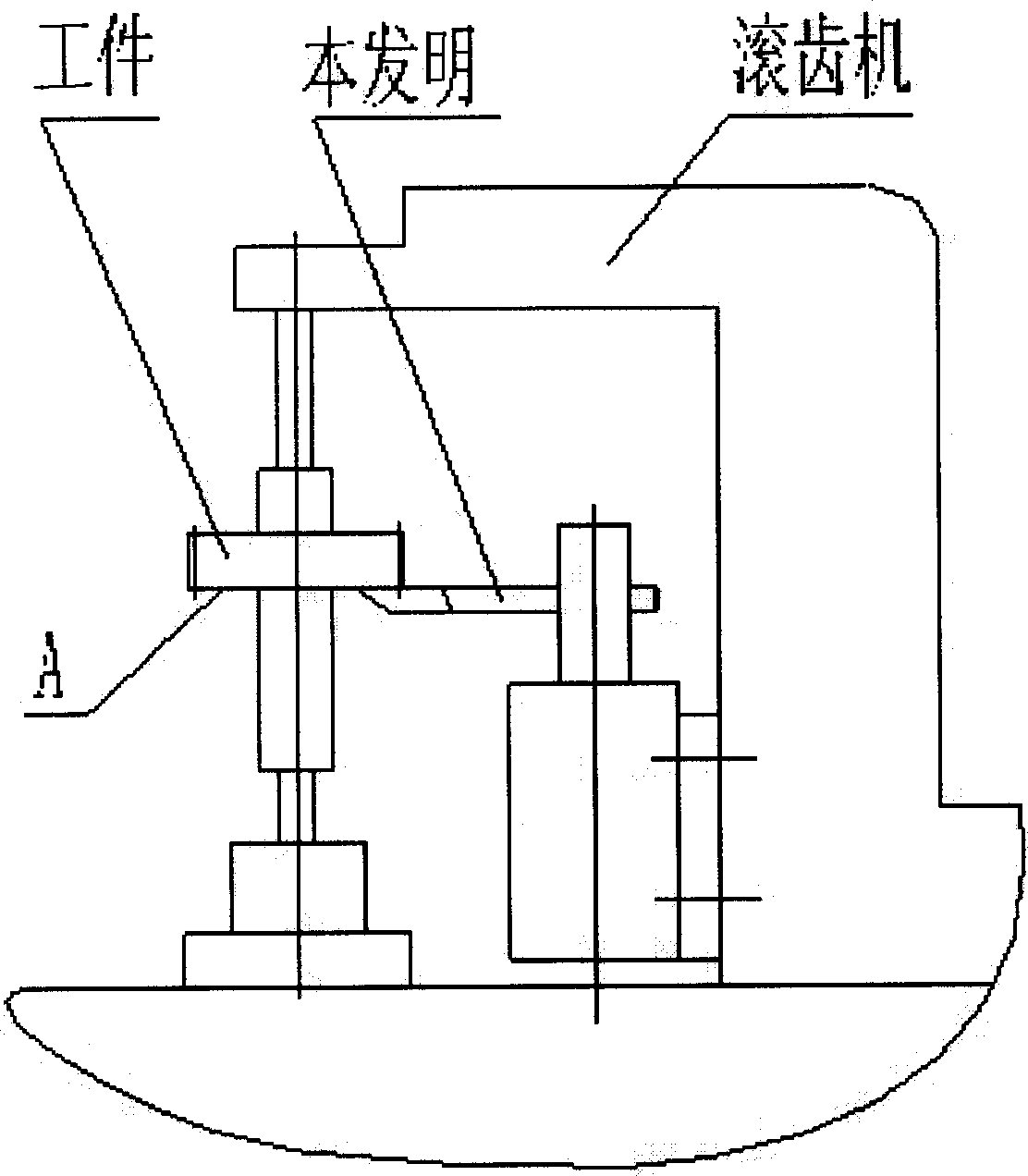

[0025] When in use, the present invention is fixed on the gear hobbing machine, so that the deburring knife 7 is close to the cutting surface A of the workpiece, and the deburring knife 7 can remove burrs while hobbing the gear.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com