Soundproof coating material and soundproof drain pipe

A covering material and drainage pipe technology, applied in the direction of pipe elements, pipes/pipe joints/pipes, mechanical equipment, etc., can solve the problems of falling off of the sound insulation layer, unable to cover the sound insulation layer, unable to ensure the sound insulation performance, etc., so as to reduce the noise of water supply and drainage. , the effect of superior operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

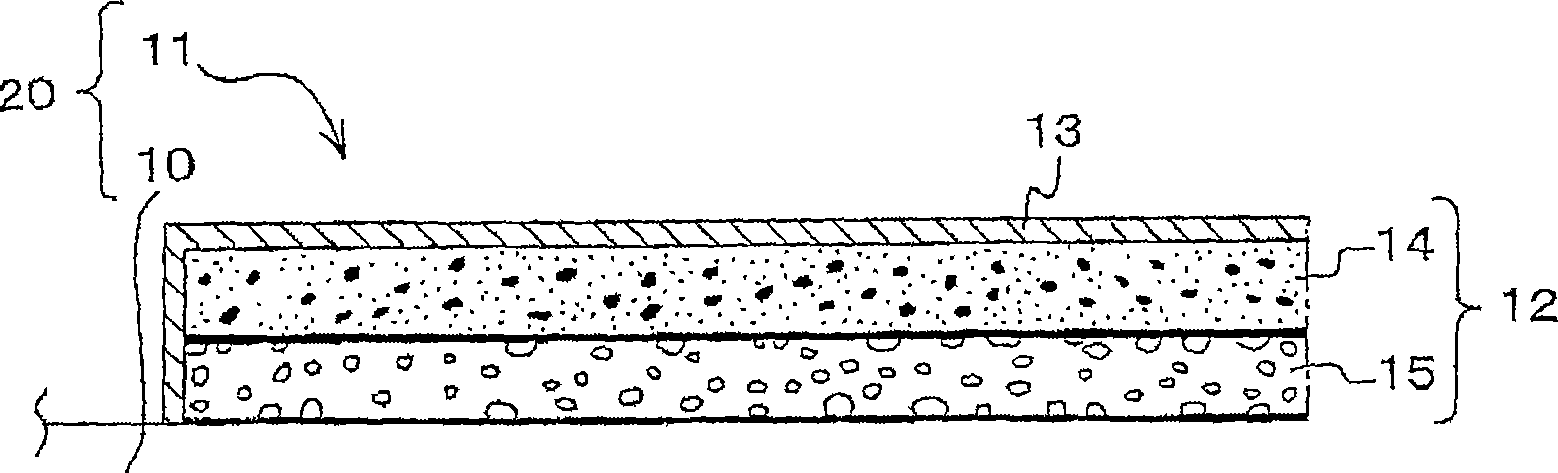

[0045] The elastic modulus is 2.1×10 with adhesive 6 Pa, the surface density is 2.3kg / m 2 A sound insulation board (SCOM2.3, manufactured by Suzuko Works Co., Ltd.) with a thickness of 1 mm and an elastic modulus of 1.0×10 3 Pa, sound-absorbing boards (molded sheets formed by pulverizing urethane, density 0.05, manufactured by Inoac Co., Ltd.) with a thickness of 5 mm were laminated to form a sound-insulating layer.

[0046] The modulus of elasticity of the sound-insulating panels constituting the above-mentioned sound-insulating layer was measured in accordance with the tensile test standard stipulated in JIS K7127. The pulling speed during the test was 50.0 mm / sec, and the distance between the chucks was 80 mm.

[0047] The modulus of elasticity of the sound-absorbing panel constituting the above-mentioned sound-insulating layer was determined in accordance with the compression test standard specified in JIS K6767. The shape of the test panel was 100×100×30 mm, and the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com