Flow-field board of fuel cell

A fuel cell and flow field plate technology, which is applied to fuel cells, fuel cell components, fuel cell additives, etc., can solve the problems of difficult proton conduction and easy occurrence of water in the front section of the diversion groove, and improve the stability. and reliability, preventing water accumulation, and improving drainage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

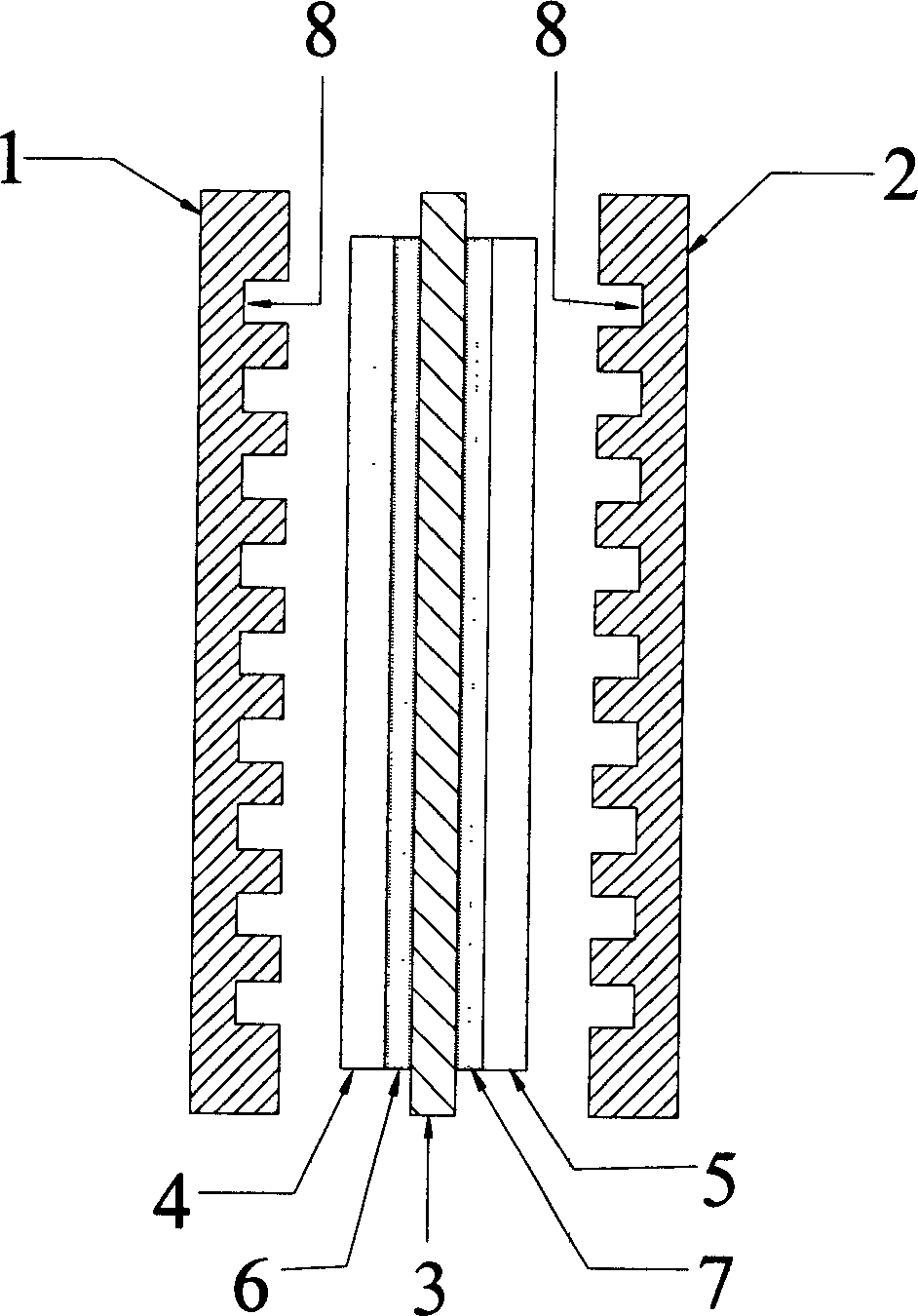

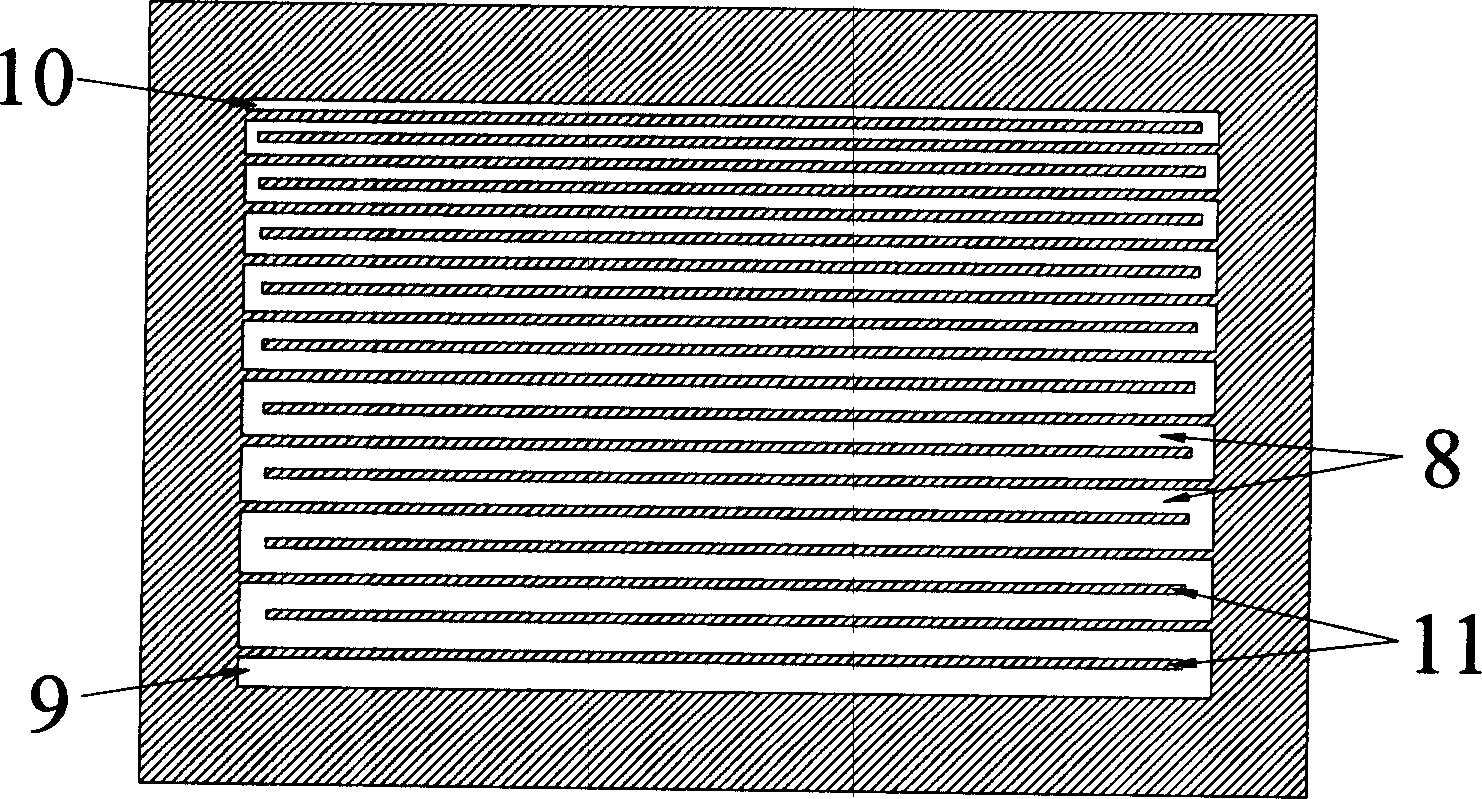

[0039] This embodiment provides a fuel cell flow field plate in which the number and depth of the flow guide grooves are constant but the width of the flow guide grooves is changed. The width of the flow guide groove on the flow field plate changes linearly.

[0040] Made of graphite material such as figure 2 The cathode flow field plate 1 and the anode flow field plate 2 are shown, and the flow field plates have gas inlet 9 and gas outlet 10, and the length, width and thickness of the flow field plates are 120 mm, 80 mm, and 1.5 mm, respectively.

[0041] In this embodiment, the diversion groove 8 on the flow field plate adopts a single diversion groove, and the diversion groove 8 is comb-shaped. The width of the diversion groove 8 gradually decreases from the gas inlet 9 to the gas outlet 10, the width of the first diversion groove on the side of the gas inlet is 3 mm, the second is 2.9 mm, the third is 2.8 mm..., the width Decrease by 0.1 mm in turn, the width of the div...

Embodiment 2

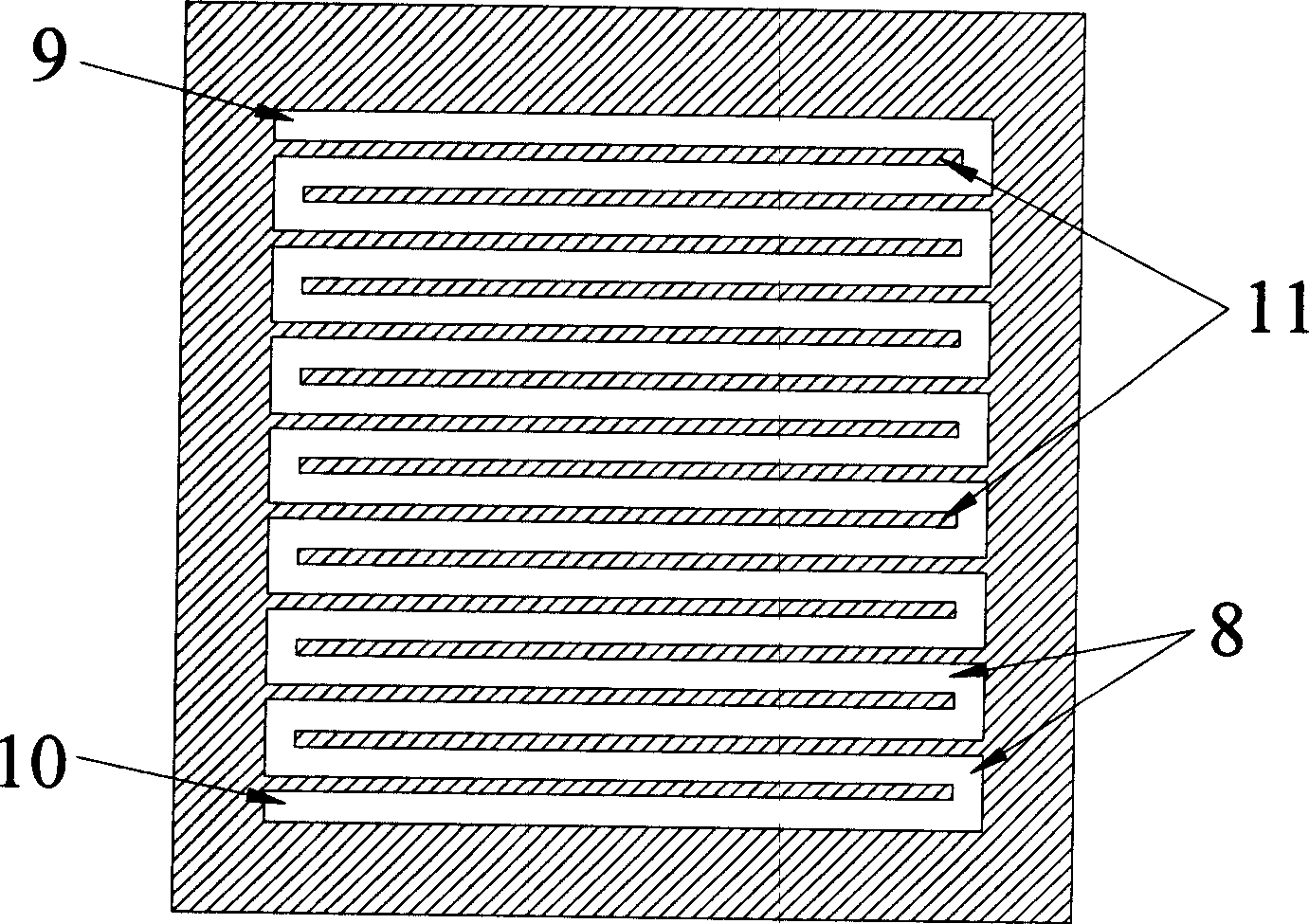

[0043] This embodiment provides a fuel cell flow field plate in which the number and width of the flow guide grooves are constant but the depth of the flow guide grooves is changed. The depth of the diversion groove on the flow field plate changes linearly.

[0044] Made of graphite material such as image 3 The cathode flow field plate 1 and the anode flow field plate 2 are shown, and there are gas inlet 9 and gas outlet 10 on the flow field plate, and the length, width and thickness of the flow field plate are 60 mm, 60 mm and 2.5 mm respectively.

[0045] In this embodiment, the diversion groove 8 on the flow field plate adopts a single diversion groove, the width of the diversion groove 8 is 2 mm, the thickness of the plate ridge 11 is 1 mm, and the depth of the diversion groove 8 is from The gas inlet 9 to the gas outlet 10 gradually decreases, the depth of the diversion groove on the gas inlet side is 1.5 mm, and the depth of the diversion groove on the gas outlet side ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com