Hinge

A technology for hinges and bases, which is applied to hinges, door/window accessories, and hinges with pins. It can solve the problems of reduced firm strength, reduced load-bearing capacity, and large opening friction, etc. Simple, simple installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

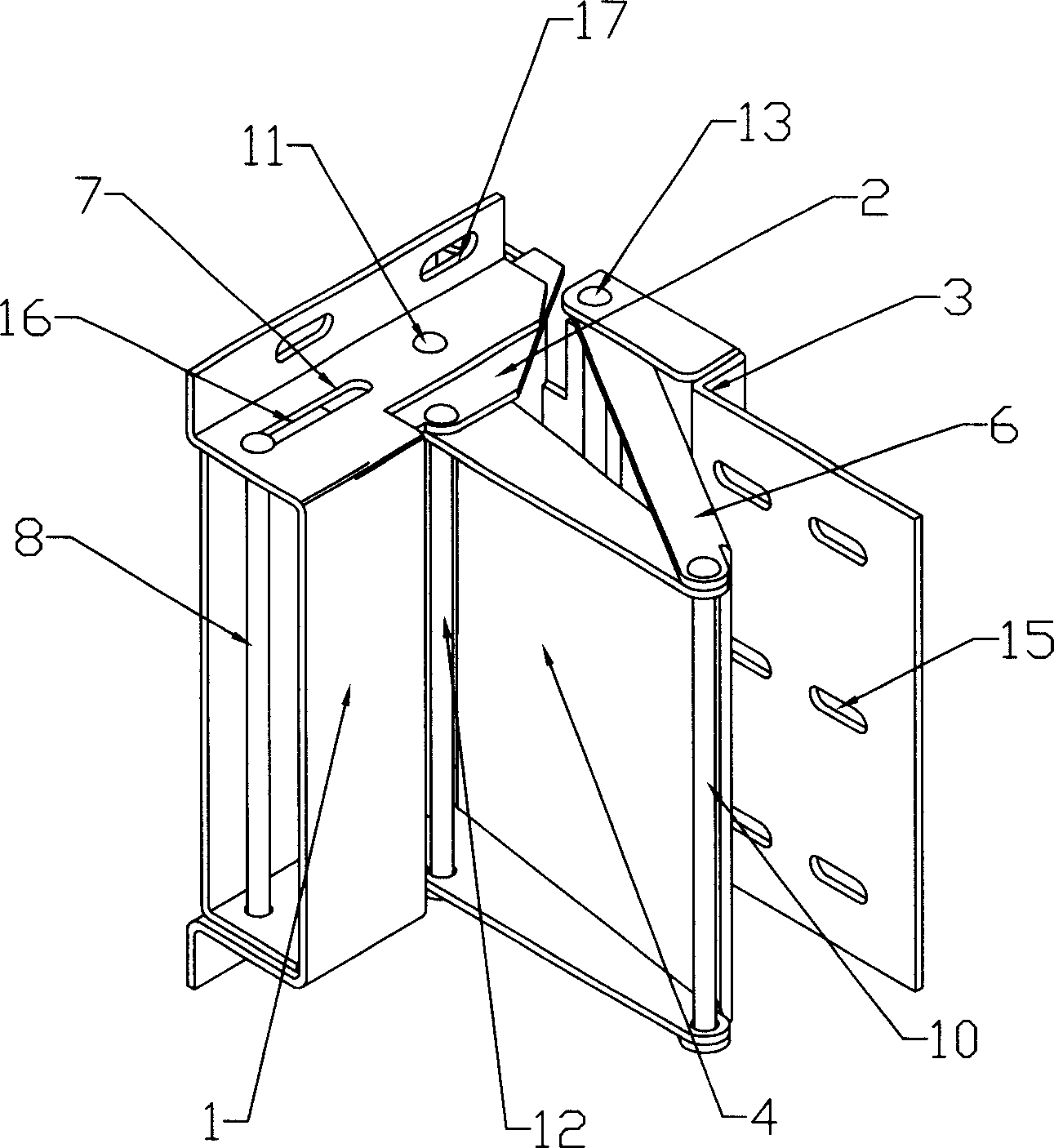

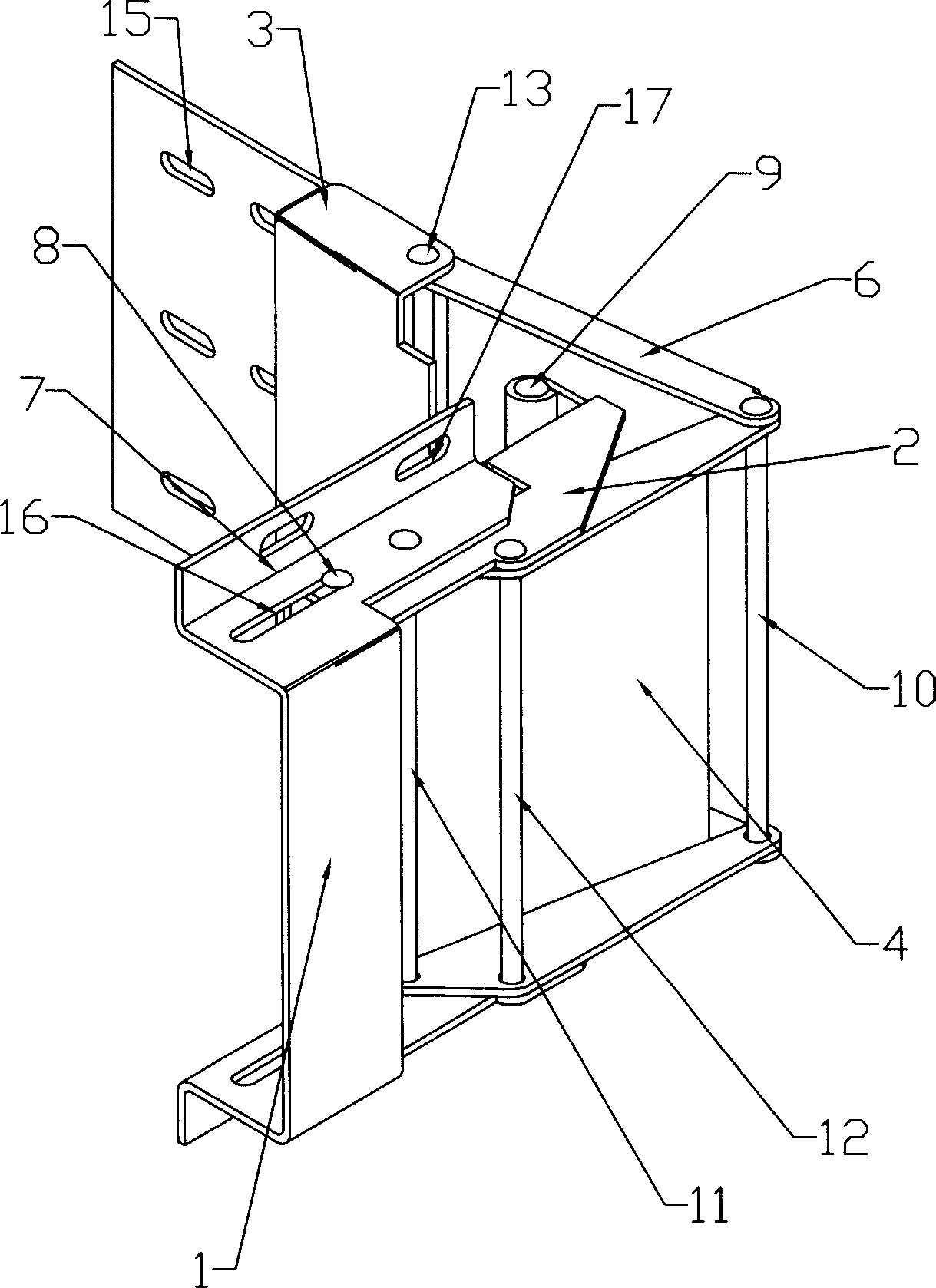

[0029] See figure 1 with figure 2 In the illustrated embodiment, the hinge of the present invention includes a base 1, a telescopic arm 2, an attachment arm 3, a first link 4, and a second link 6. The base 1 is used to install on a door or window frame; the telescopic arm 2 is arranged on the base 1, and can move on the base 1 in a direction perpendicular to the rotation axis of the door leaf; the attachment One end of the arm 3 is pivotally connected to one end of the telescopic arm 2 through an f-axis 9, and the other end of the attachment arm 3 is used to install the door leaf or window sash; one end of the first link 4 passes through the fulcrum b-axis 11 Is pivotally connected to the base 1; the second link 6 is pivotally connected to the first link 4 and the attachment arm 3 through the a-axis 10 and the d-axis 13; The telescopic arm 2, the attachment arm 3, the first link 4, and the second link 6 constitute a four-link mechanism; wherein, the first link 4 is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com