Method for preparing cyclo pentadiene and methyl cyclopentadiene by carbon 9 and carbon 10 distillation

A technology for methylcyclopentadiene and crude methylcyclopentadiene is applied in the field of pyrolysis and rectification to produce cyclopentadiene and methylcyclopentadiene, which can solve the problem of wasting, methylcyclopentadiene is very Less effective utilization and other issues, to achieve the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

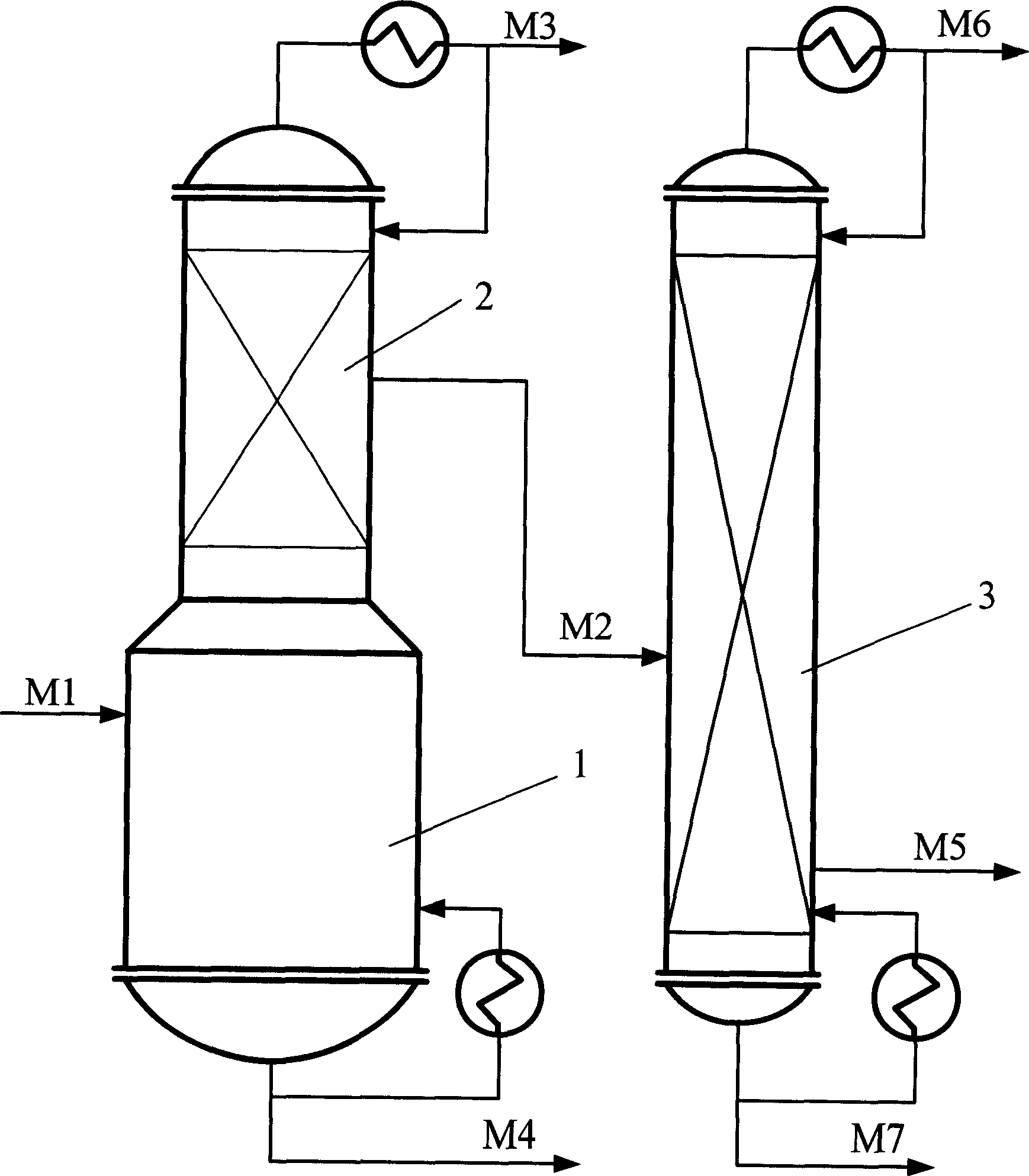

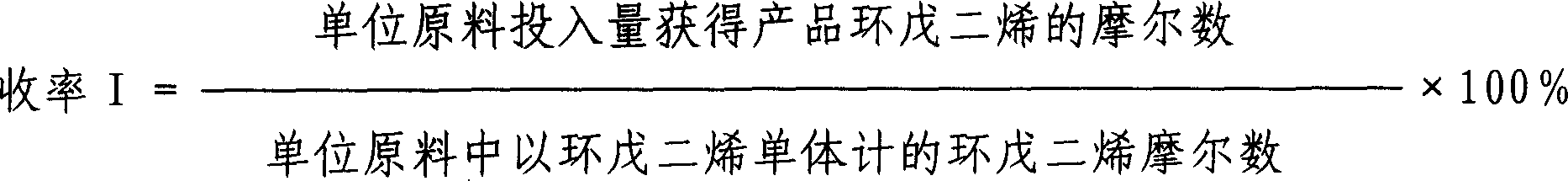

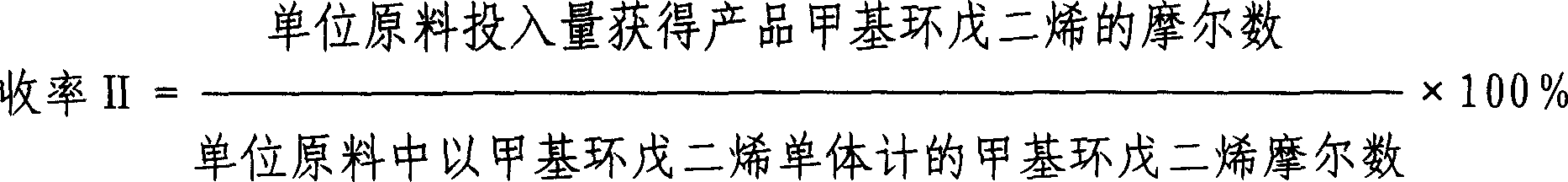

[0020] The flow chart of each embodiment is shown in the accompanying drawings. The volume of the cracking kettle 1 is 50 liters, and the rectifying tower 2 is a sieve tray tower with 25 theoretical plates. The feed rate of raw material M1 and the discharge rate of cracking raffinate M3 are controlled to obtain the required cracking residence time. The rectifying column 3 is a sieve tray column with 30 theoretical plates. The outlet for obtaining the crude methylcyclopentadiene material from the side line is located at a temperature of 62-70°C in the rectifying section. The main process conditions of each embodiment cracking rectification device and methylcyclopentadiene product refining rectification tower are shown in Tables 1 and 2, and the yield and purity of product refined cyclopentadiene and refined methylcyclopentadiene are shown in Table 1. Table 2. in:

[0021]

[0022]

[0023]

cracking temperature

(℃)

cleavage stay

t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com