Method for preparing low-iror anhydrous sodium sulfide by one-step reduction of Glauber salt from coke oven gas

A technology of anhydrous sodium sulfide and coke oven gas, which is applied in the direction of alkali metal sulfide/polysulfide, can solve the problems of serious environmental pollution and high energy consumption, and achieve the effect of saving energy and overcoming serious pollution and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

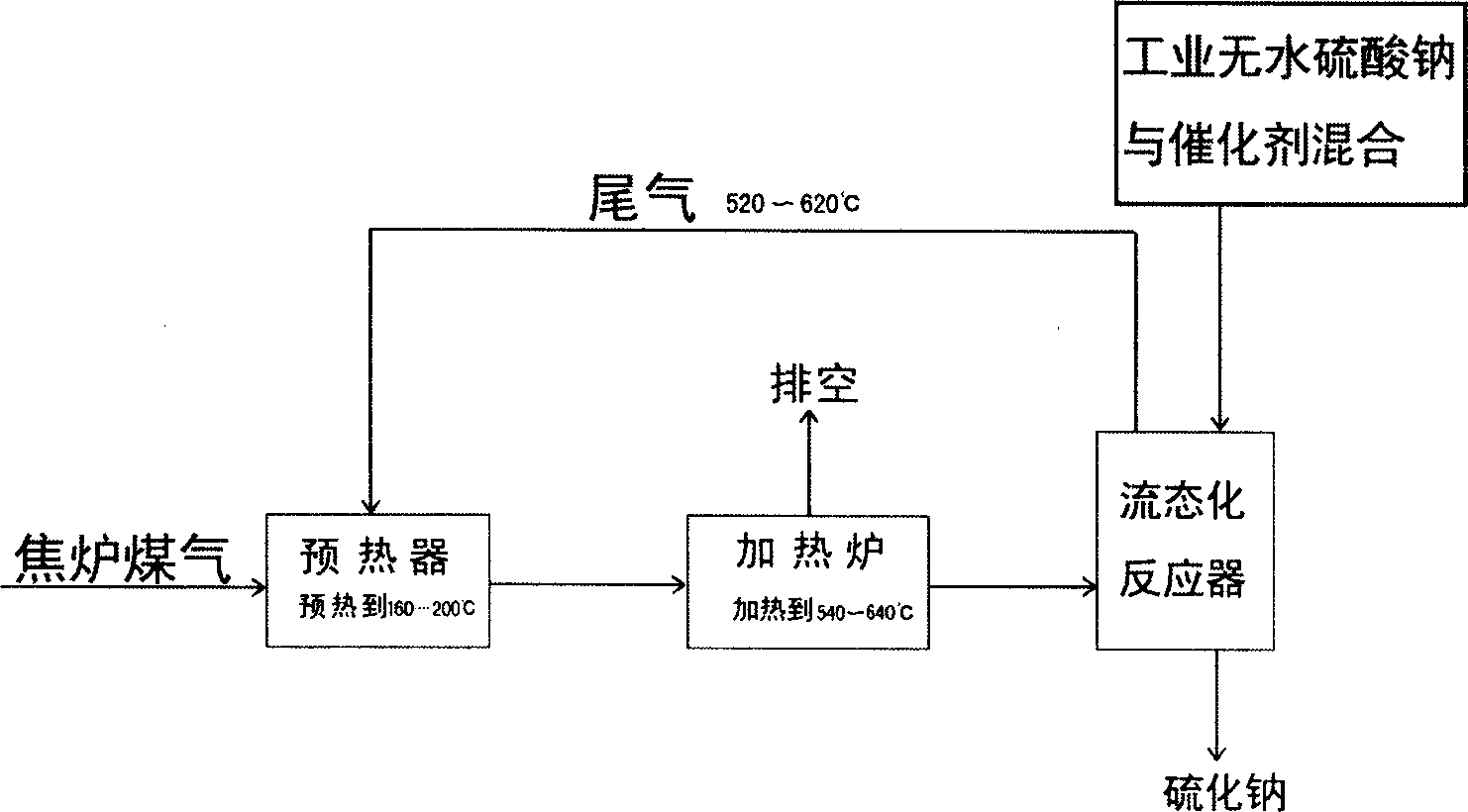

[0012] Embodiment 1: the preparation method of coke oven gas one-step reduction Glauber's salt system low-iron anhydrous sodium sulfide is based on the production of 1 ton of low-iron anhydrous sodium sulfide, and the preparation method includes the following steps:

[0013] 1) after getting 1800 kilograms of industrial anhydrous sodium sulfates and 9 kilograms of vanadium pentoxides to mix, add from the tower top through the feeder, the sodium sulfide generated after the reaction is discharged from the discharge at the bottom of the fluidized bed;

[0014] 2) 1800 standard cubic meters of coke oven gas is pressurized to 0.03Mpa by the blower, preheated to 160°C in the preheater, and then heated to the reaction temperature of 540°C in the heating furnace, and then sent to the bottom of the fluidized bed reactor, Inside the chemical bed reactor, coke oven gas reacts with sodium sulfate to generate sodium sulfide—that is, the prepared sodium sulfide meets the standard of Class 3 ...

Embodiment 2

[0016] Embodiment 2: the preparation method of coke oven gas one-step reduction Glauber's salt system low-iron anhydrous sodium sulfide is based on the production of 1000 kilograms of low-iron anhydrous sodium sulfide, and the preparation method includes the following steps:

[0017] 1) After getting 1800 kilograms of industrial anhydrous sodium sulfate and 18 kilograms of ferric oxide and mixing, add from the top of the tower through a feeder, and the sodium sulfide generated after the reaction is discharged from the bottom of the fluidized bed;

[0018] 2) 2,500 standard cubic meters of coke oven gas is pressurized to 0.05Mpa by a blower, preheated to 200°C in a preheater, and then heated to a reaction temperature of 640°C in a heating furnace, and then sent to the bottom of a fluidized bed reactor. Inside the chemical bed reactor, coke oven gas reacts with sodium sulfate to generate sodium sulfide—that is, the prepared sodium sulfide meets the standard of Class 3 low-iron an...

Embodiment 3

[0020] Embodiment 3: the preparation method of coke oven gas one-step reduction Glauber's salt system low-iron anhydrous sodium sulfide is based on the production of 1000 kilograms of low-iron anhydrous sodium sulfide, and the preparation method includes the following steps:

[0021] 1) After getting 1800 kilograms of industrial anhydrous sodium sulfate and 11 kilograms of ferric oxide to mix, add from tower top through feeder, the sodium sulfide that generates after reaction is discharged from fluidized bed bottom discharge;

[0022] 2) 2,200 standard cubic meters of coke oven gas is pressurized to 0.04Mpa by a blower, preheated to 180°C in a preheater, and then heated to a reaction temperature of 590°C in a heating furnace, and then sent to the bottom of a fluidized bed reactor. Inside the chemical bed reactor, coke oven gas reacts with sodium sulfate to generate sodium sulfide—that is, the prepared sodium sulfide meets the standard of Class 3 low-iron anhydrous industrial so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com