Correcting method for dynamic measured position of photoelectronic width measurer

A dynamic measurement and correction method technology, applied in the field of photoelectric detection, can solve the problems of large jump and tilt, damage to the basic conditions of imaging measurement, measurement errors, etc., and achieve the effect of correcting measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following is based on Figure 3 ~ Figure 5 A preferred embodiment of the present invention is given and described in detail to better illustrate the technical features and functional characteristics of the present invention, but it is not used to limit the scope of the present invention.

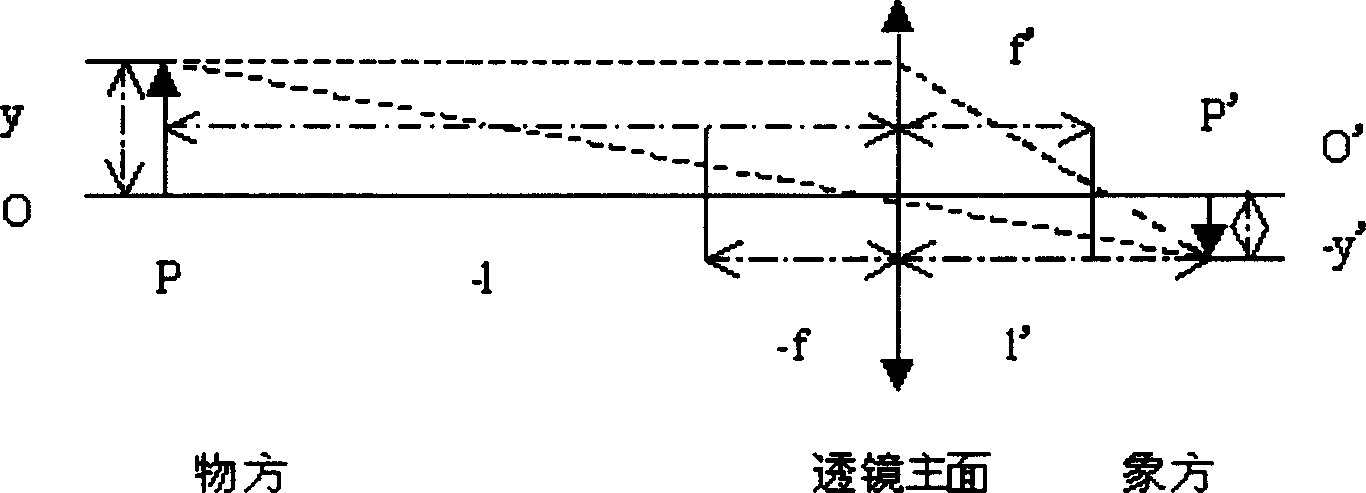

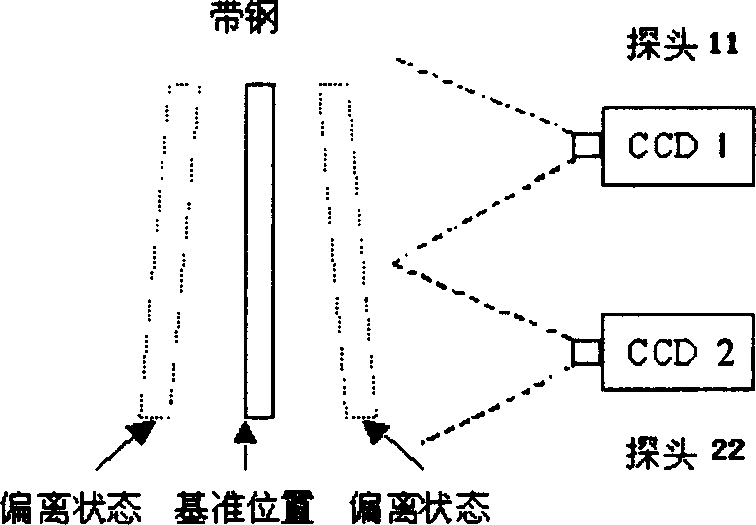

[0018] see image 3 , The detection system of the present invention is composed of two groups of CCD cameras, and each group of cameras is composed of an optical system and a linear array CCD device. The strip width measurement adopts the passive imaging measurement method, and the two sets of cameras respectively acquire the images of the strip edge, and obtain the width value through calculation. According to the distance measurement principle of the binocular vision method, two sets of cameras can measure the distance information of the two edges of the strip at the same time, thereby forming a measurement system combining width measurement and distance measurement, and realiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com