Elevator without mechanical room

A technology without mechanical rooms and elevators, which is applied in the directions of elevators, transportation and packaging in buildings, which can solve the problems of reduced service life of slings, difficulty in saving space in the height direction, difficulty in effective use of space and high speed, and achieve saving effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

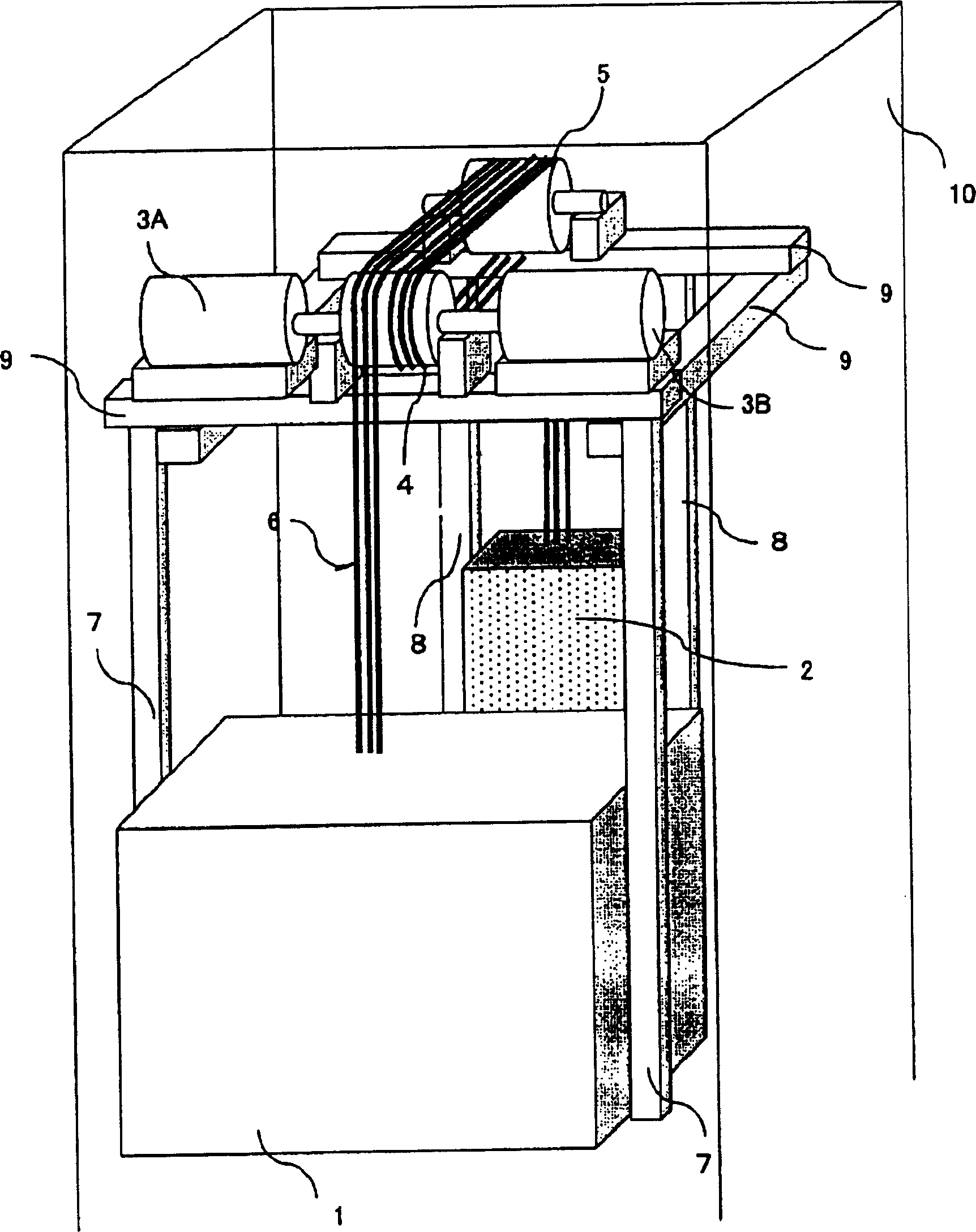

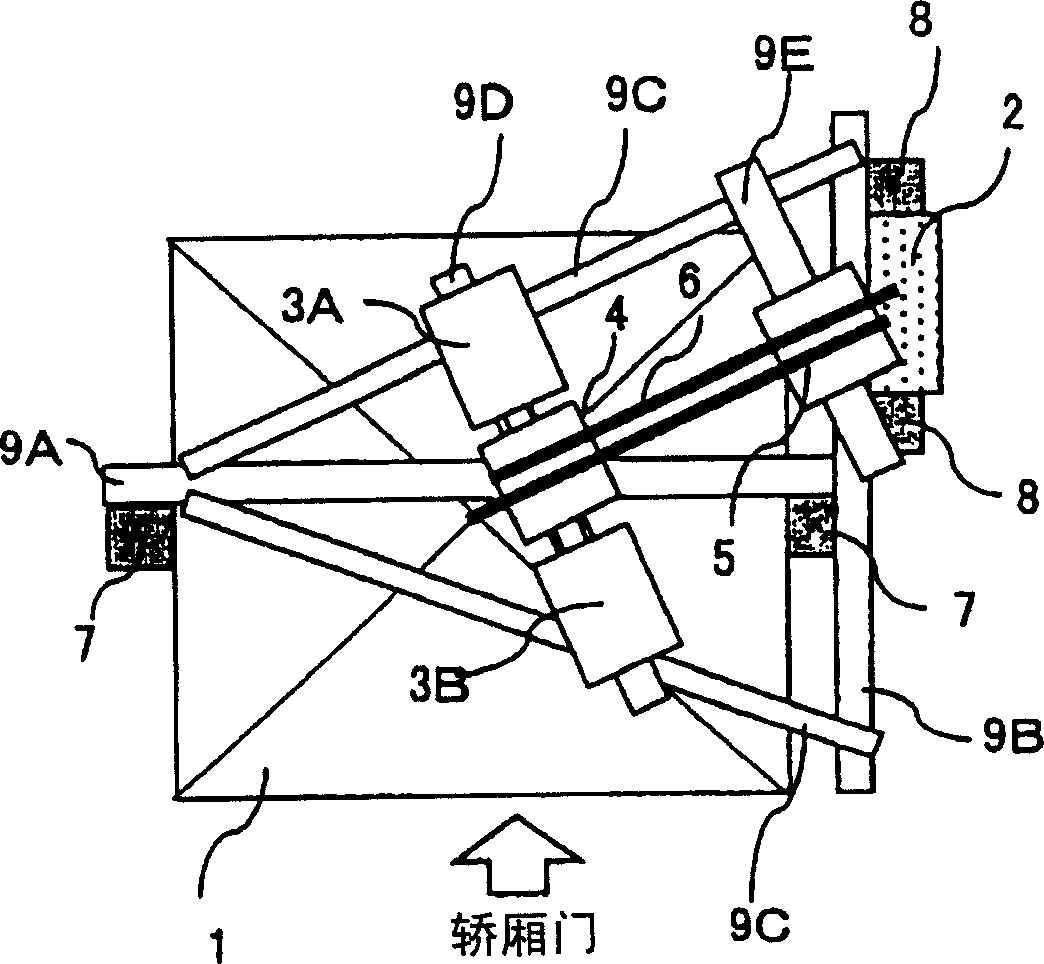

[0022] Embodiments of the present invention will be described below with reference to the drawings.

[0023] figure 1 is an overall configuration diagram of an elevator without a machine room as an embodiment of the present invention, figure 2 yes figure 1 The top view of the balance counterweight set at the rear of the elevator car, image 3 yes figure 1 The top view when the balance weight is set on the side of the elevator car, Figure 4 is a side view showing the relationship between the diameter of the drive sheave and the diameter of the sling, Figure 5 yes figure 1 An enlarged view of the driving sheave part, Figure 6 is a configuration diagram showing an embodiment of a power conversion device, Figure 7 yes Figure 6 The block diagram of the control circuit section, Figure 8 It is a test chart showing the measured torque waveform when the phase difference of the magnetic pole position is 0 degrees. Figure 9 It is a test chart showing the measured torque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com