Electromagnetic clutch

An electromagnetic clutch and machine technology, applied in clutches, magnetic drive clutches, non-mechanical drive clutches, etc., can solve the problem of inability to reduce the outer diameter of the second rotating body, reduce the adsorption area of the armature plate, increase the power consumption of the electromagnetic clutch, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

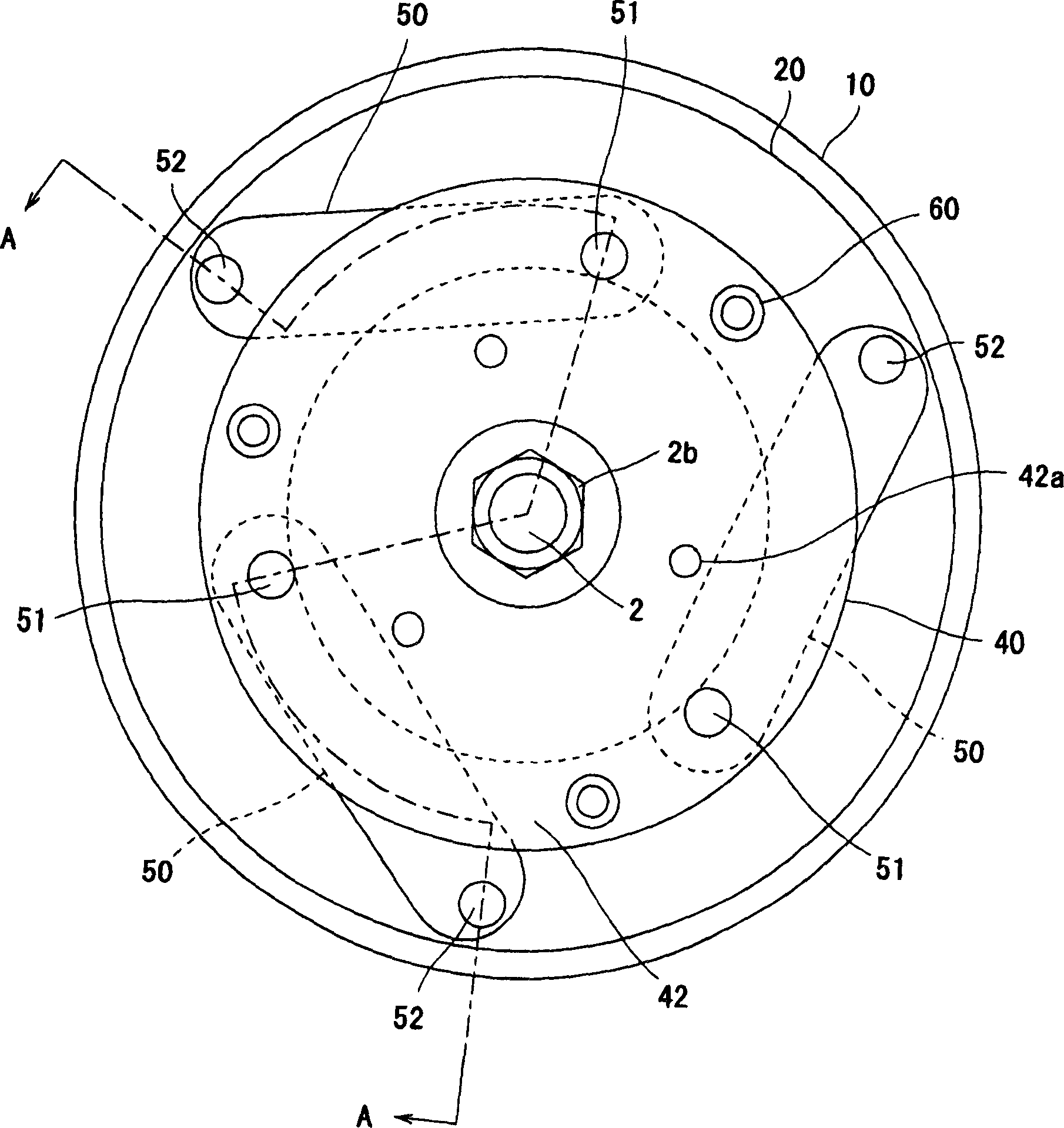

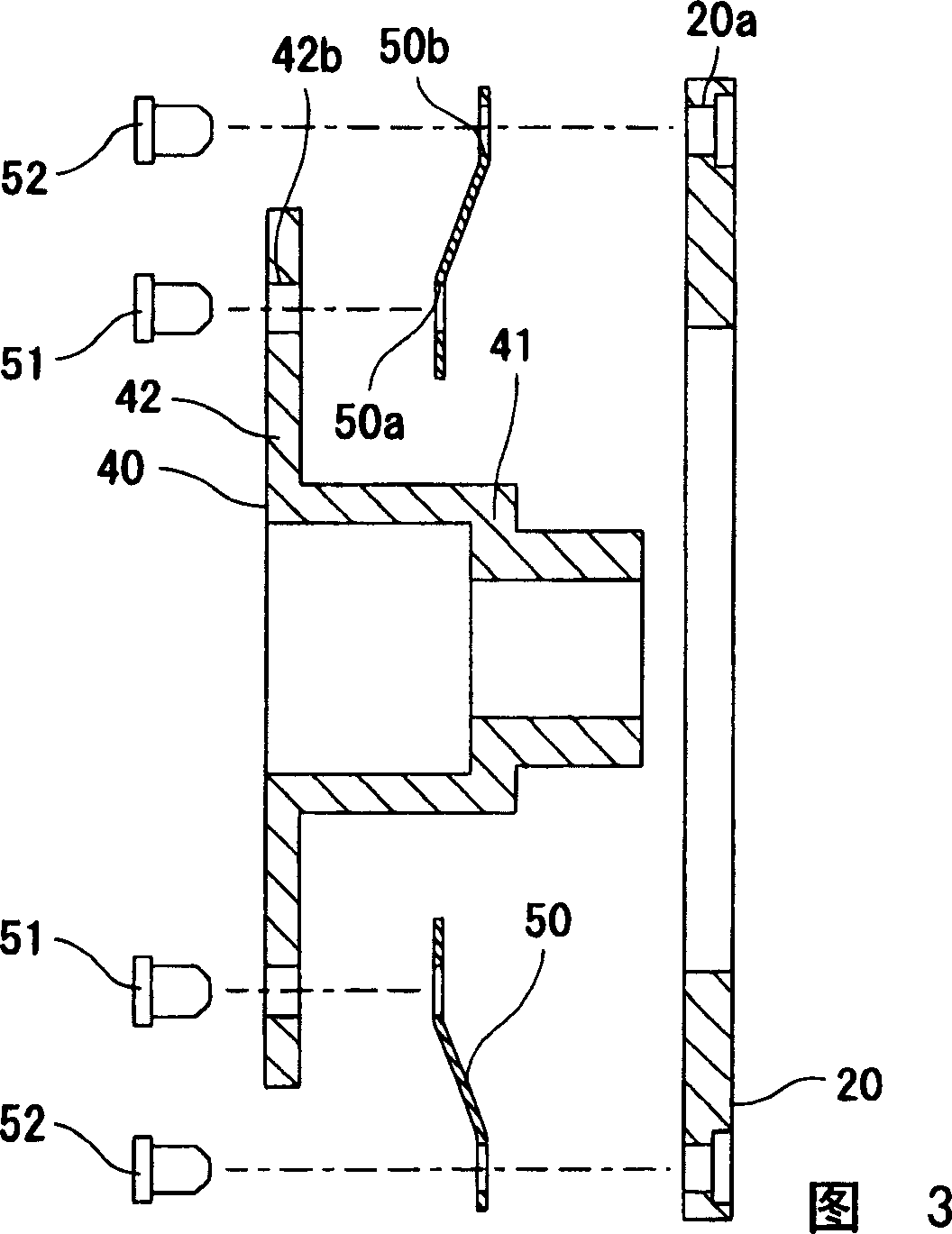

[0021] Figure 1 to Figure 4 An embodiment of the present invention is shown. figure 1 is the front view of the electromagnetic clutch, figure 2 for figure 1 Figure 3 is a side sectional view of the armature plate, the second rotating body and each leaf spring before assembly, Figure 4 It is a side cross-sectional view showing a state in which an armature plate with a small inner diameter is assembled with a second rotating body and each leaf spring.

[0022] The electromagnetic clutch of this embodiment is provided with: the first rotating body 10 is transmitted with the power from the engine not shown in the figure; Connected to the first rotating body 10; the electromagnetic coil 30 is used to attract the armature plate 20 to the first rotating body 10 side; the second rotating body 40 has another armature plate 20 with a predetermined distance in the axial direction. An extension part 42 provided with facing end faces is connected to the rotating shaft 2 of the compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com