Trackless door with pedrail

A kind of crawler and door frame technology, applied in the direction of gates/doors, door/window fittings, buildings, etc., can solve the problems of unstable use, environmental noise pollution, increase the cost of raw materials and processing costs, and achieve the effect of improving linearity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

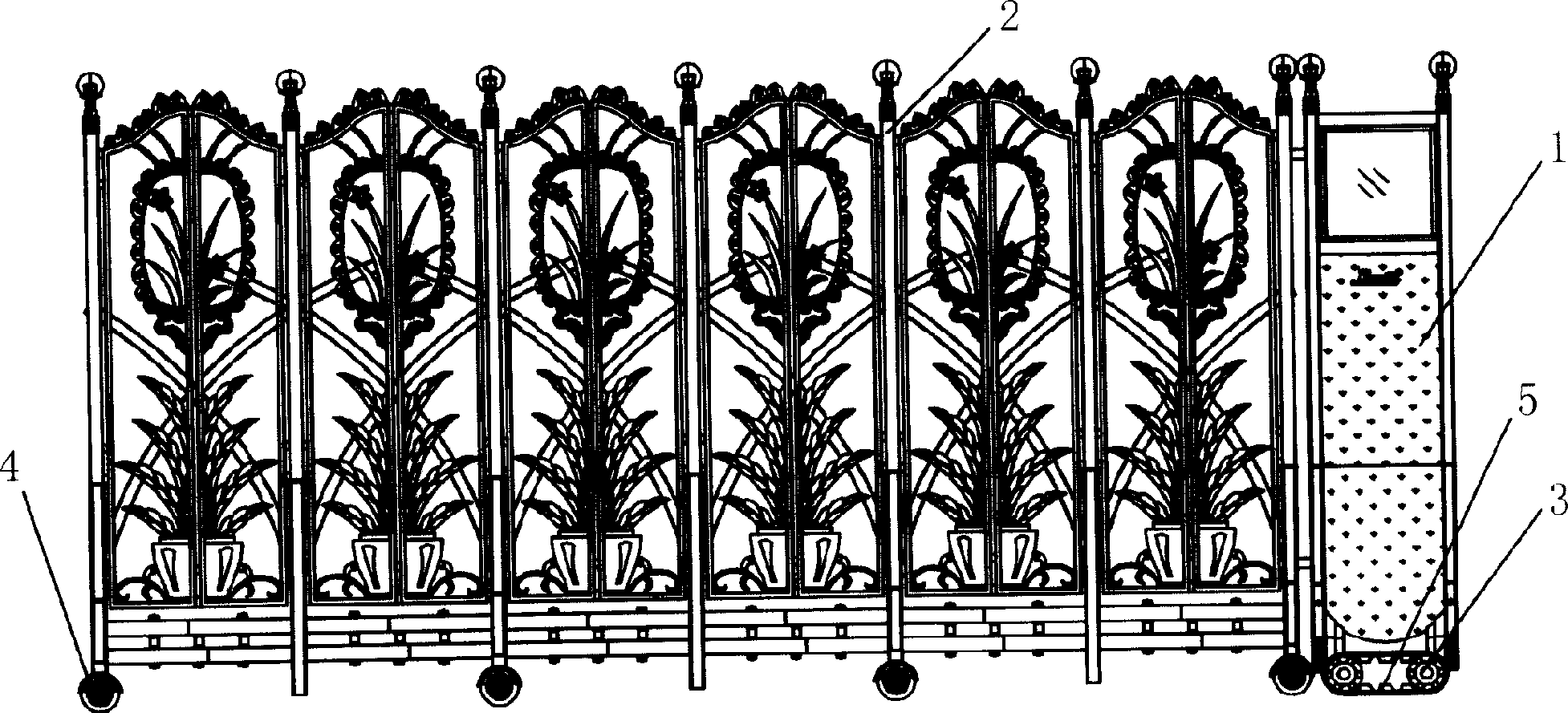

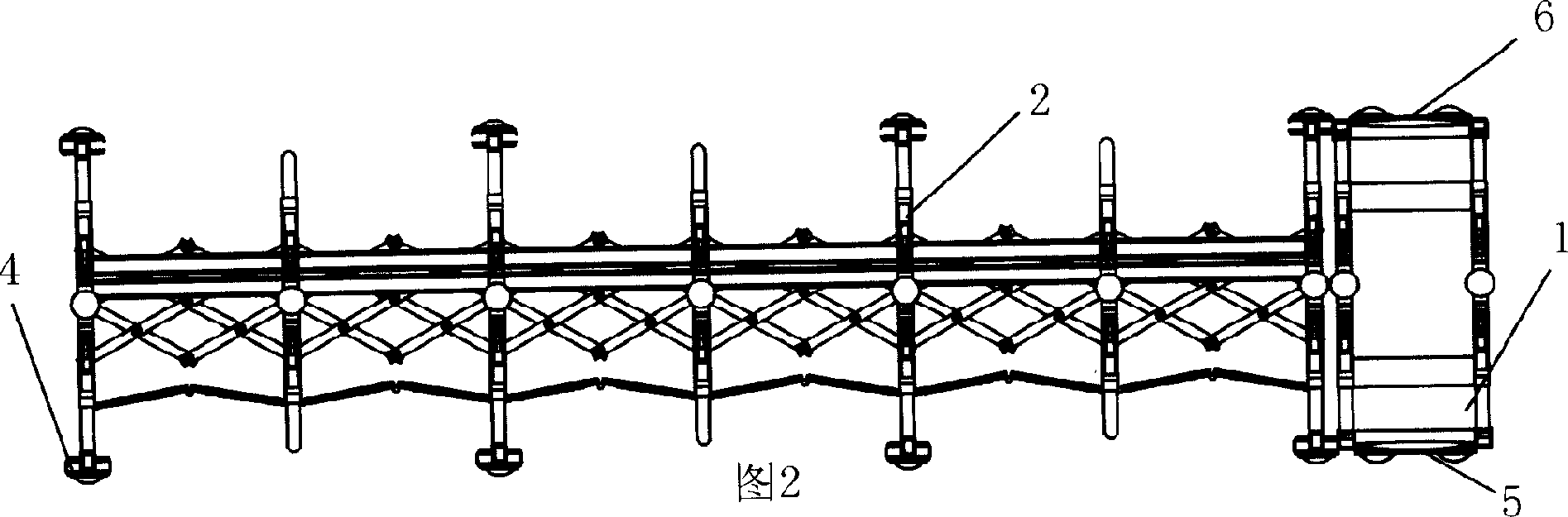

[0022] Embodiment one: refer to figure 1 ,figure 2, Figure 5 , Figure 6 , Fig. 9, Fig. 10, construct a kind of crawler trackless door, comprise machine head 1, a plurality of door frames 2 connected in turn, be arranged in the driving device in machine head 1, be arranged on the travel drive wheel 3 of both sides of machine head 1 bottom 1. The walking wheels 4 arranged on both sides of the lower end of the door frame also include two annular walking crawlers 5 and 6 respectively coated on the walking driving wheels 3 on both sides, and the inner surfaces of the annular walking crawlers 5 and 6 are provided at intervals. There are many grooves 7 that are evenly distributed, and the annular surface of the driving wheel 3 on both sides of the lower part of the head 1 is provided with an annular limiting groove 8, and the two side walls of the annular limiting groove 8 are provided with a plurality of evenly distributed through holes Hole 9, tooth pin 10 is housed in through ...

Embodiment 2

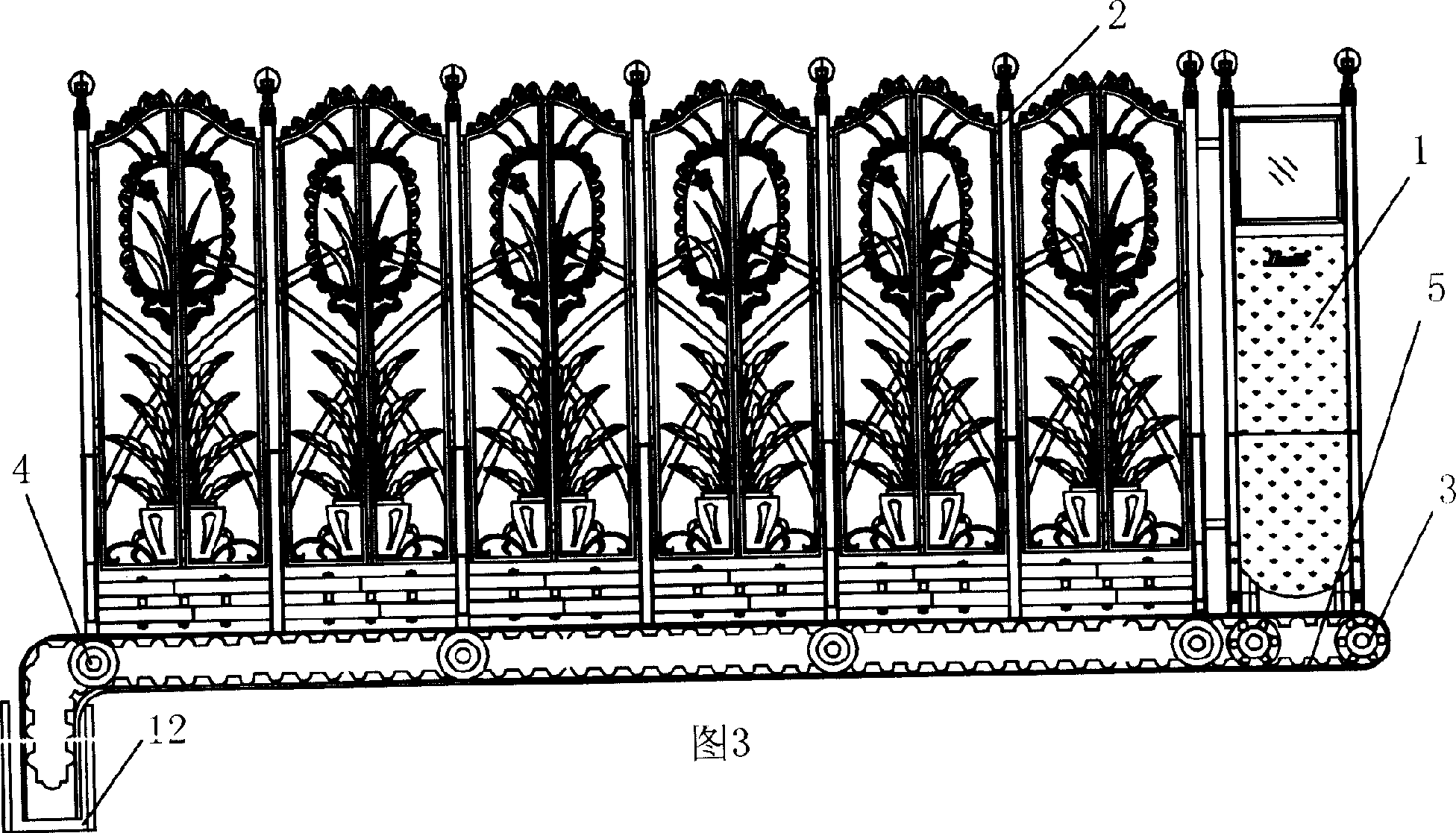

[0025] Embodiment two: with reference to Fig. 3, Fig. 4, Figure 5 , Figure 6 , Figure 7 , Figure 8 , Fig. 9, Fig. 10, construct a kind of crawler trackless door, comprise machine head 1, a plurality of door frames 2 connected in turn, be arranged in the driving device in machine head 1, be arranged on the travel drive wheel 3 of both sides of machine head 1 bottom 1. The walking driving wheel 3 is connected to the driving device in transmission, and the walking wheel 4 arranged on both sides of the lower end of the door frame 2 also includes two annular walking crawler belts 5 that are respectively coated on the walking driving wheel 3 and the walking wheel 4 on both sides. , 6, grooves 7 are arranged at intervals on the inner surface of the ring-shaped walking crawler belt 5, 6, and ring-shaped limiting grooves 8 are provided on the annular surfaces of the walking wheels 4 at the lower ends of a plurality of door frames 2. The section shapes of crawler belts 5 and 6 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com