Probe for an atomic force microscope

A kind of atomic force microscope, microscope technology, applied in scanning probe technology, parts of instruments, instruments, etc., can solve the problem of inability to measure the interaction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

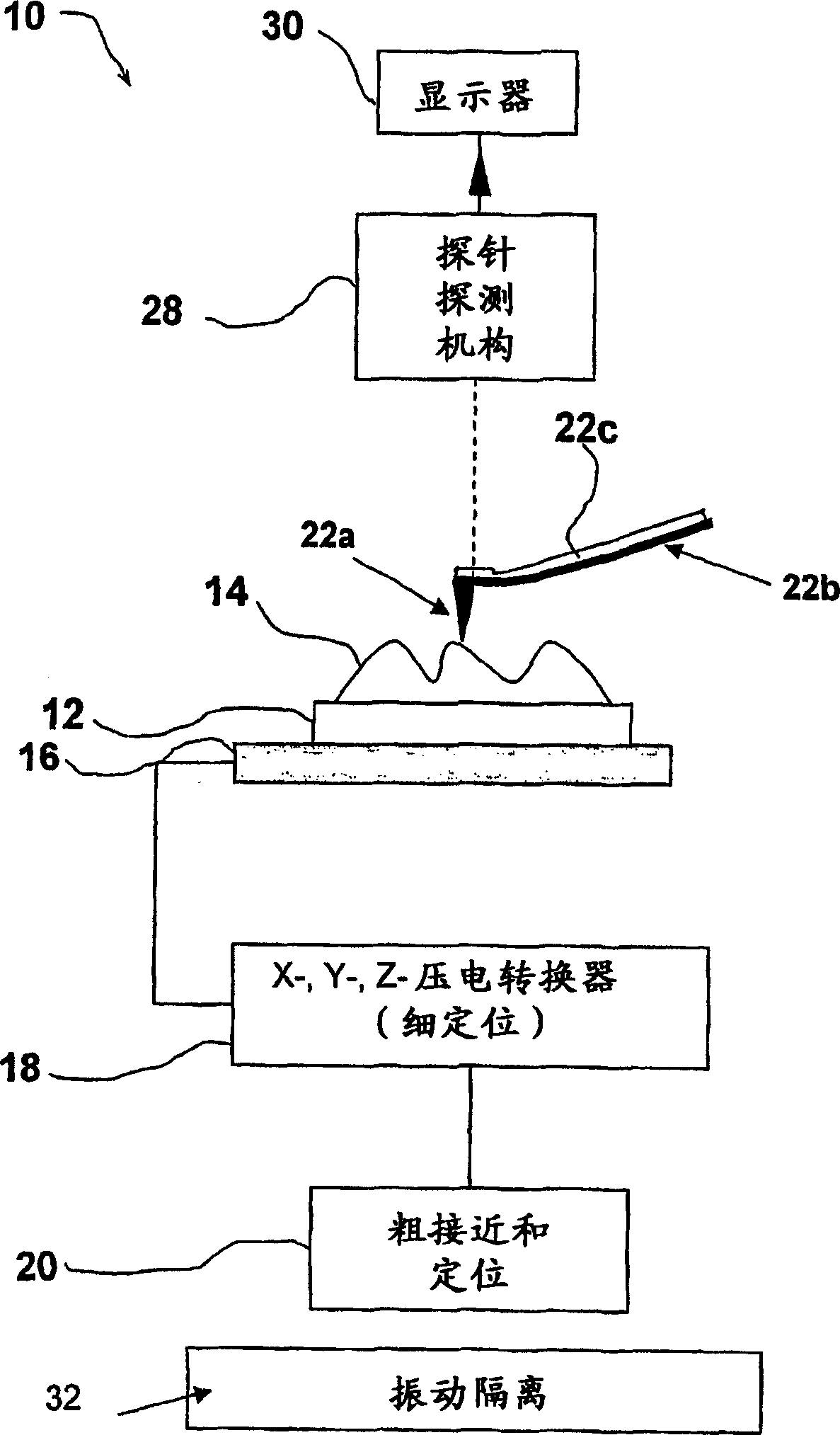

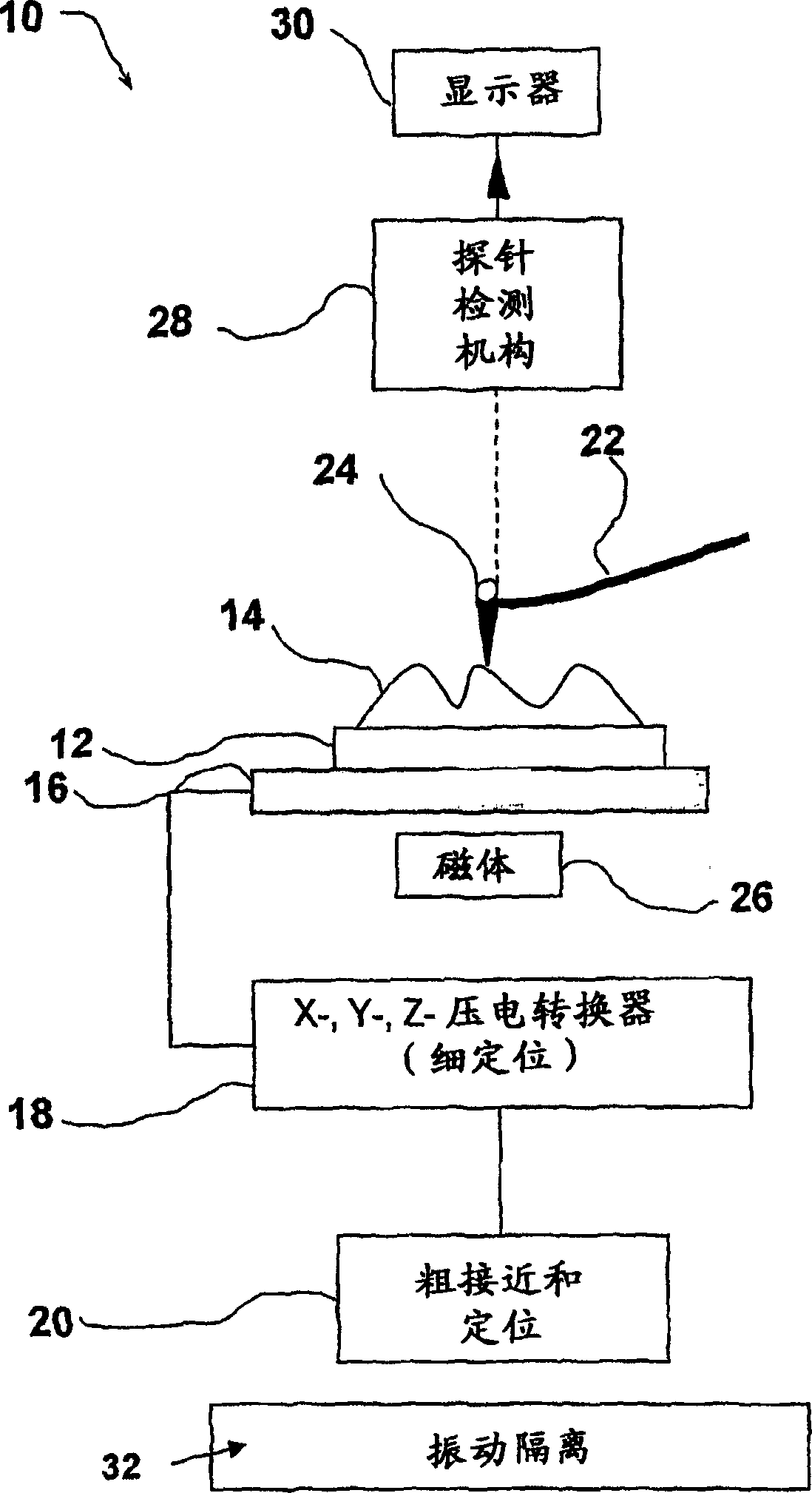

[0046] refer to figure 2 A schematic implementation of an AFM, indicated generally at 10, using a first embodiment of a probe constructed in accordance with an aspect of the invention is shown. The illustrated AFM apparatus 10 includes a plate 12 adapted to carry a sample 14 and mounted on one arm of a tuning fork 16 . The tuning fork 16 is connected to a piezoelectric transducer 18 and a coarse drive 20 . A piezoelectric transducer 18 is used to drive the sample 14 (along with the plate 12 and tuning fork 16) in three dimensions x, y and z. It is common in the art to take the z-axis of the Cartesian coordinate system to be perpendicular to the plane occupied by the sample 14 . That is, the interaction force depends not only on the xy position of the probe 22 above the sample 14 (imaged pixel), but also on its height above. A tuning fork control (not shown) is arranged to apply a sinusoidal voltage to the tuning fork 16 to excite resonant or near-resonant vibrations in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com