Process for producing graphitizing petrol coke by Acheson graphitizing furnace

A technology of graphitization furnace and petroleum coke, which is applied in the petroleum industry, coking ovens, etc., and can solve problems such as unstable quality, incapable of large-scale production, and low market supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

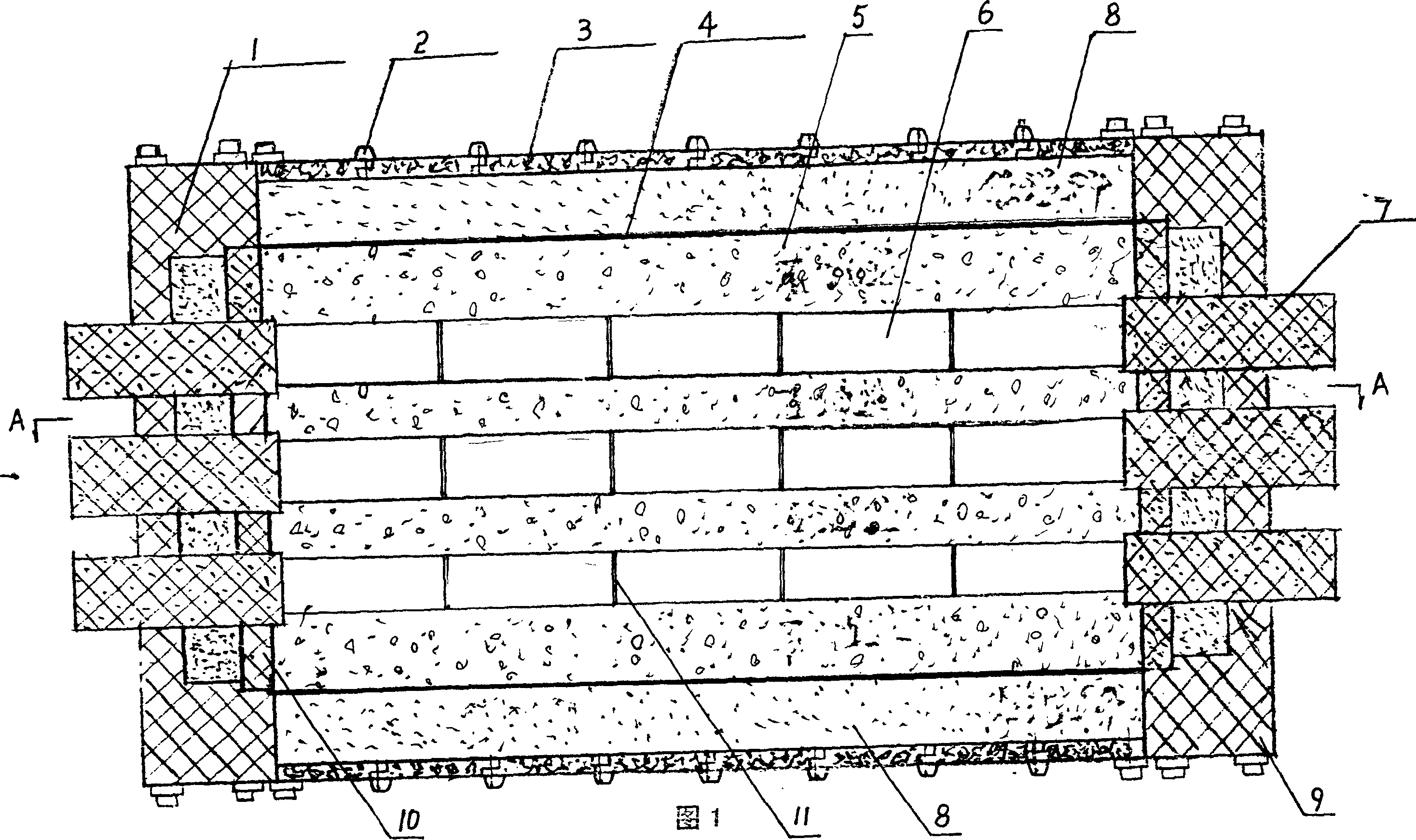

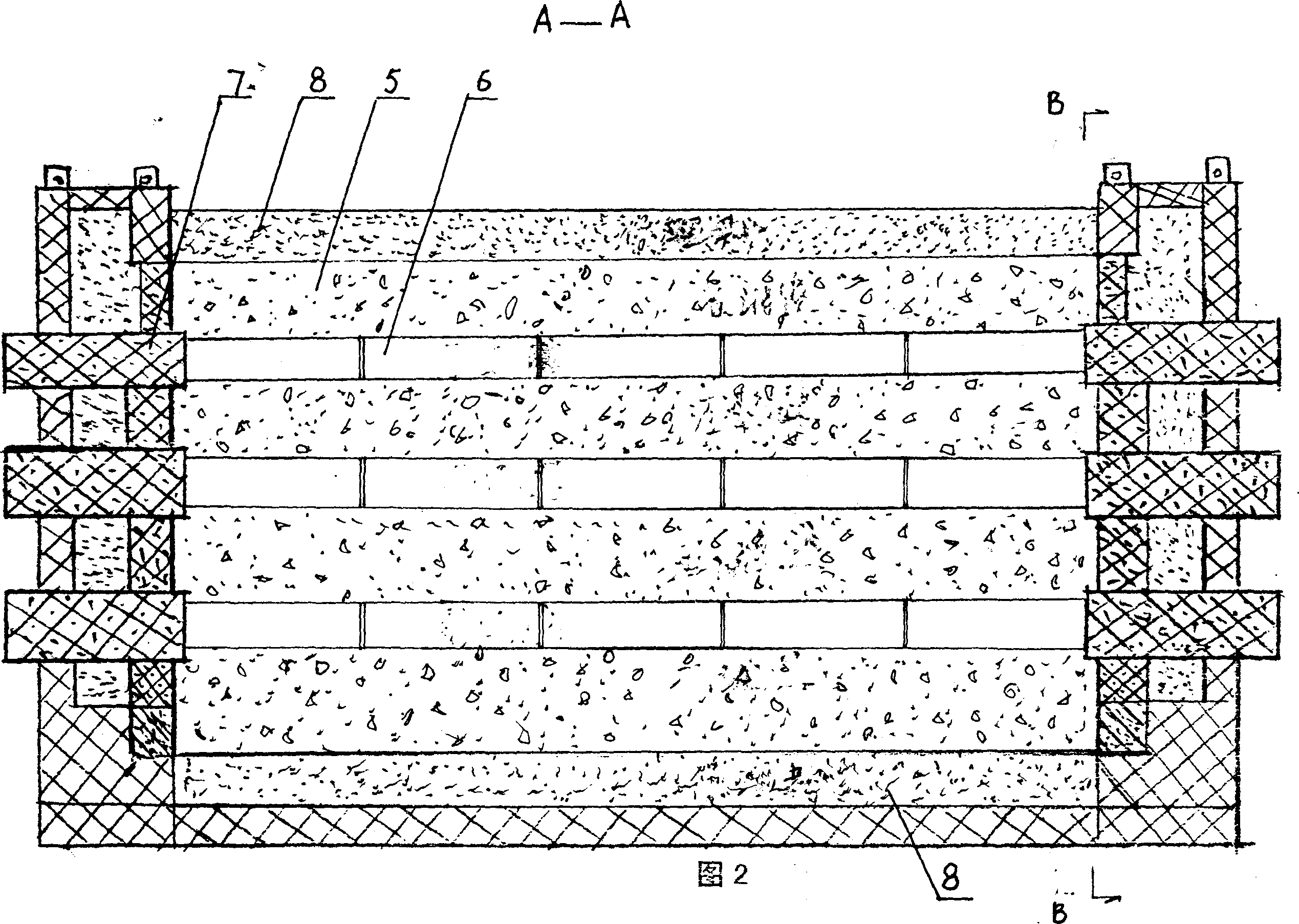

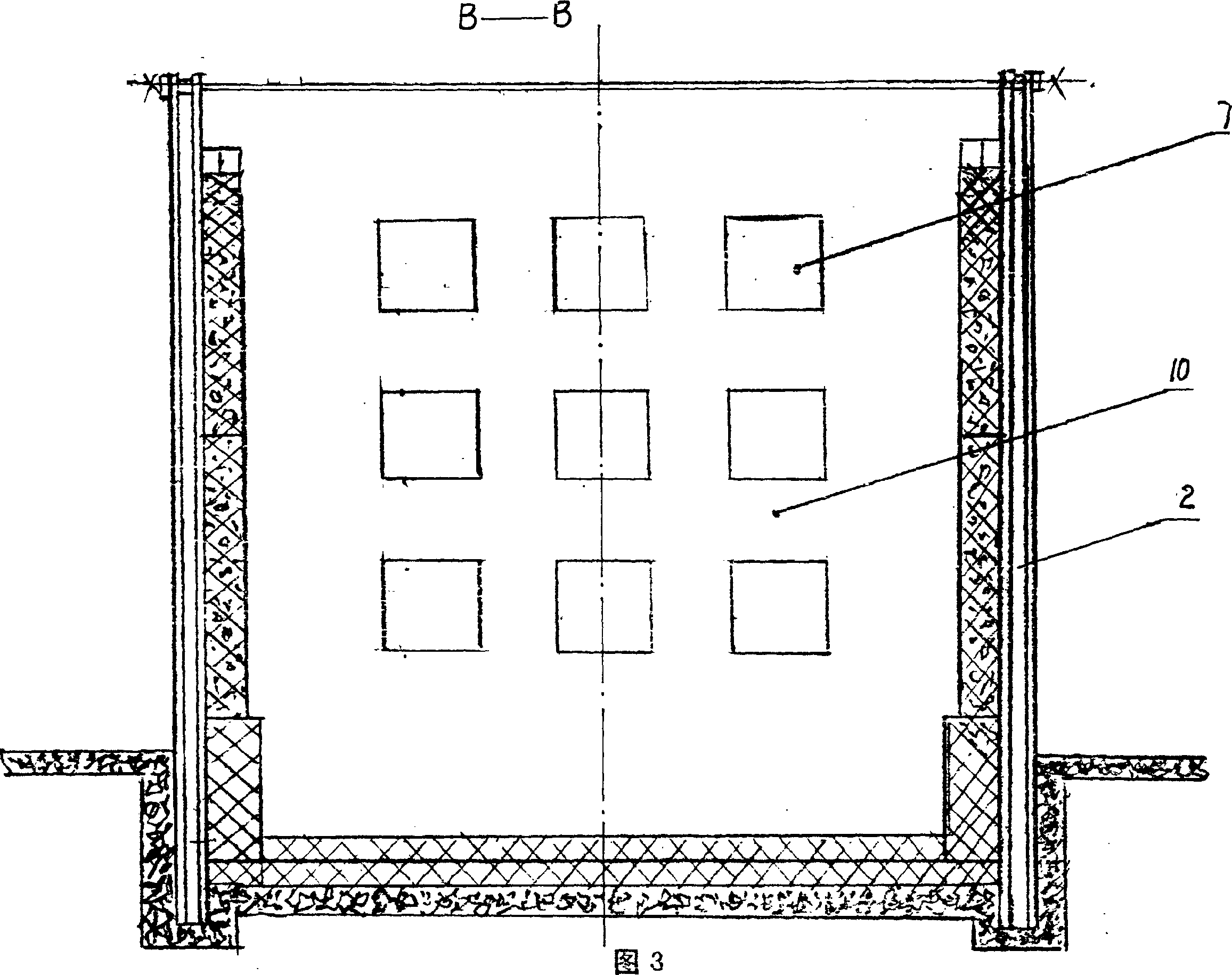

[0012] The embodiment of the present invention is shown in accompanying drawing, utilizes the Acheson furnace equipment to carry out production, and the bottom of the furnace is paved with thermal insulation material 8 at a distance of 400 mm from the bottom of the lower conductive electrode 7, and the furnace type plate 4 is used to encircle a rectangular furnace type, and the second layer is paved in the furnace. A layer of petroleum coke 5, the first layer is paved to the bottom of the lower conductive electrode 7 of the furnace head and tail in the furnace, and then compacted, and then the second layer is laid corresponding to the conductive electrodes 7 of the furnace head 1 and the furnace tail 9 of the Acheson furnace. A layer of baked carbon material is used as the conductive heating core 6, and there are three conductive heating cores in the lower layer, each of which is connected by 7 pieces of 1.8-meter-long carbon material baked products. When the length is not suita...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com