High-energy electron-diffraction diagram processing system and method

A high-energy electron diffraction and image processing technology, applied in electrical digital data processing, chemical instruments and methods, and input/output process of data processing, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

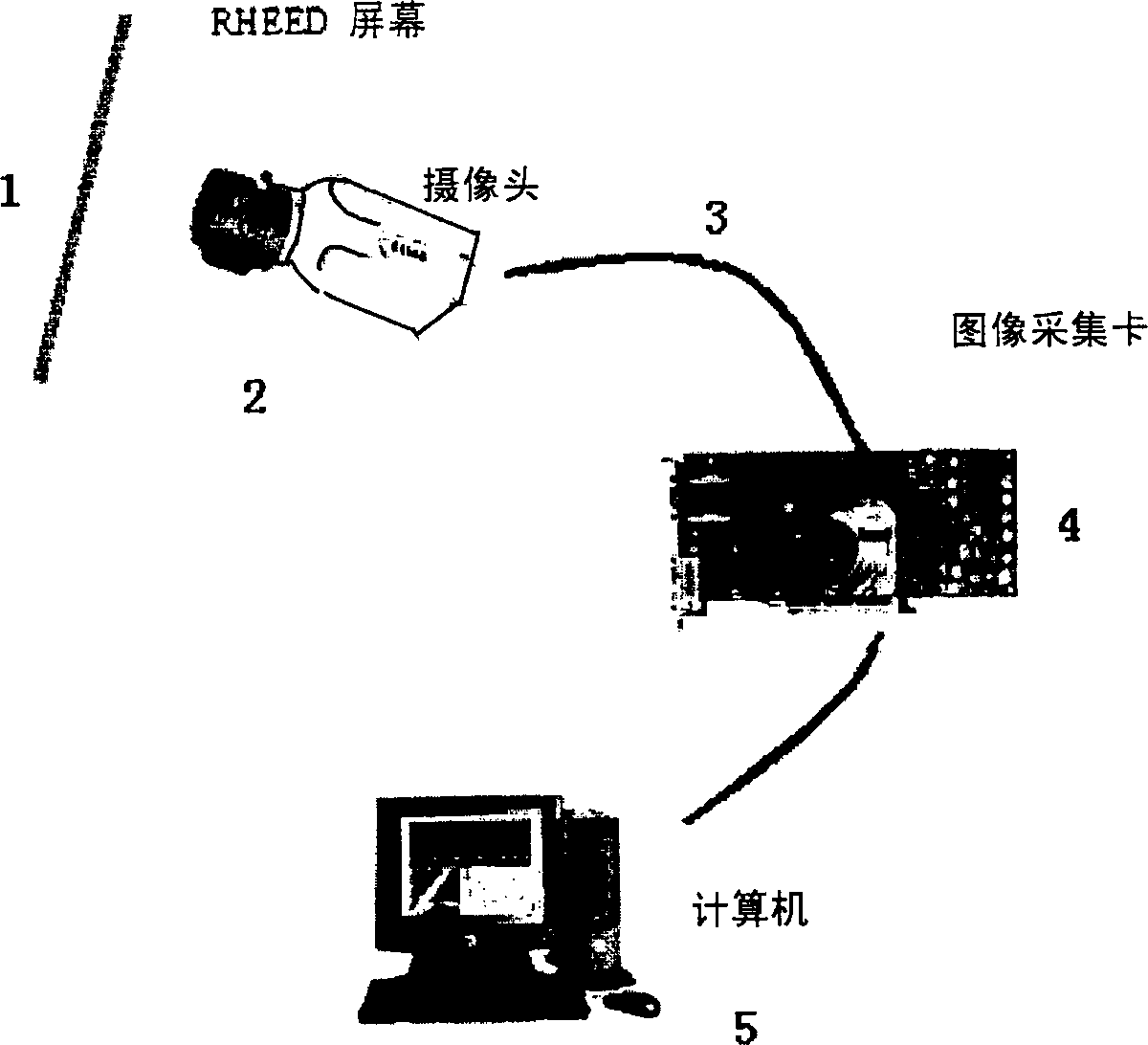

[0035] see figure 2 , figure 2 It is a connection diagram of each component of the system. A high-energy electron diffraction image processing system of the present invention is characterized in that it includes:

[0036] A high-energy electron diffraction fluorescent screen 1;

[0037] A CCD camera 2, the CCD camera 2 is placed behind the high-energy electron diffraction fluorescent screen 1, and the CCD camera is fixed with a stainless steel cylinder;

[0038] An image acquisition card 4, the image acquisition card 4 is connected with the CCD camera 2 with the video line 3, and the image acquisition card 4 converts the analog signal obtained by the CCD camera 2 into a digital signal, and stores it in the memory;

[0039] A computer 5, the computer 5 is connected with the image acquisition card 4 with the video line 3, the computer 5 processes the data in the internal memory, and images the data on the screen of the computer 5.

[0040] 2. A high-energy electron diffract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com