Ultrasonic connection head and device employing same

A bonding device and ultrasonic technology, applied in the direction of vibrating fluid, non-electric welding equipment, electrical components, etc., can solve the problems of screw looseness and damage, and achieve the effect of easy maintenance and low-cost structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Hereinafter, an embodiment of an ultrasonic bonding apparatus having an ultrasonic bonding head according to the present invention will be described with reference to the drawings.

[0044] In addition, in this embodiment, the case where the electronic component with a bump which is a chip component is mounted on a board|substrate is demonstrated as an example. In addition, other chip components include IC chips, semiconductor chips, optical elements, surface mount components, etc., and represent all forms on the side bonded to the substrate regardless of the type and size of the wafer or the like.

[0045] In addition, as a board|substrate, a resin board|substrate, a glass board|substrate, a film board|substrate etc. are mentioned, for example, and it shows all forms of the side bonded to a chip component.

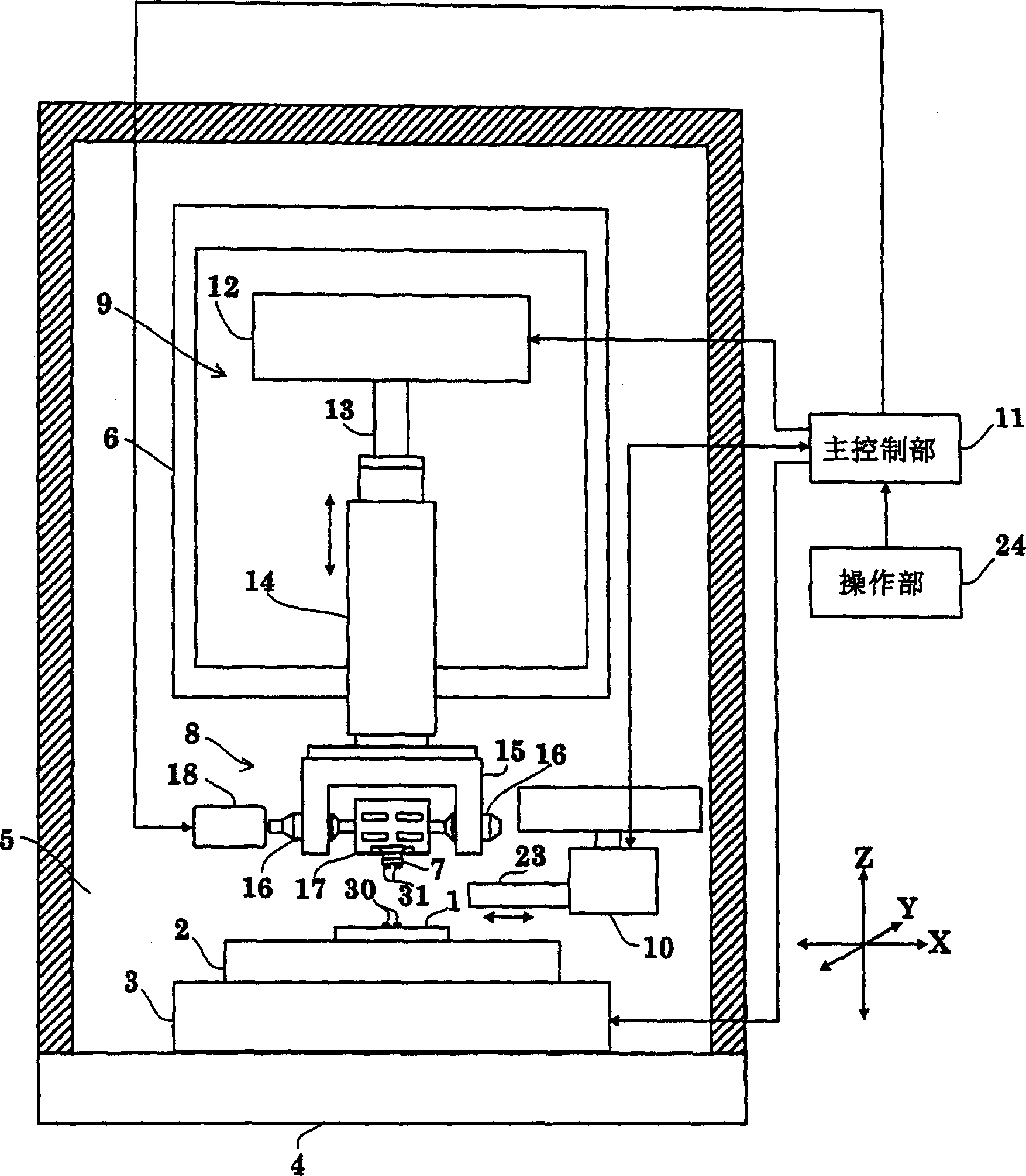

[0046] figure 1 It is a front view of the key acoustic wave bonding apparatus related to this embodiment.

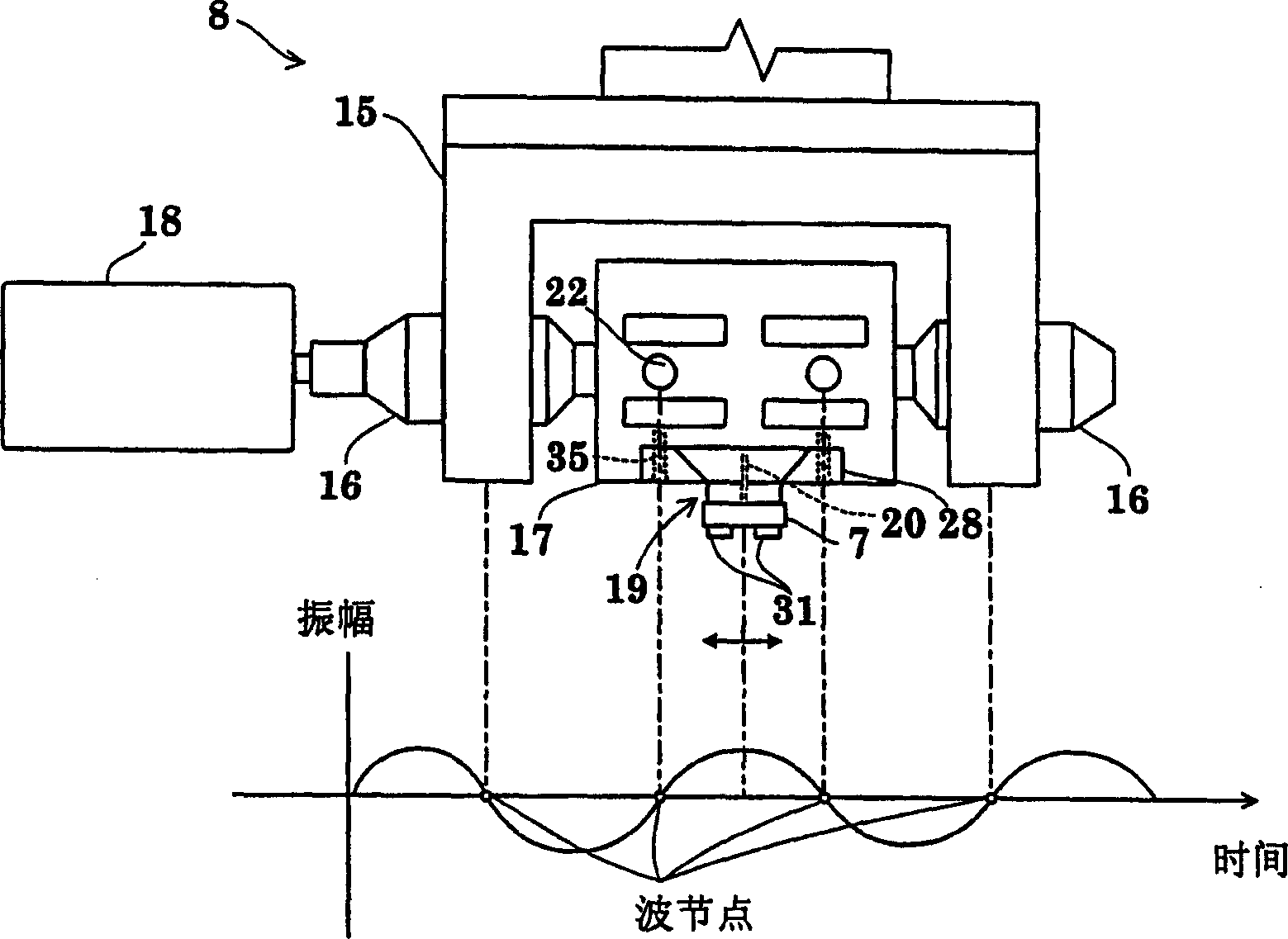

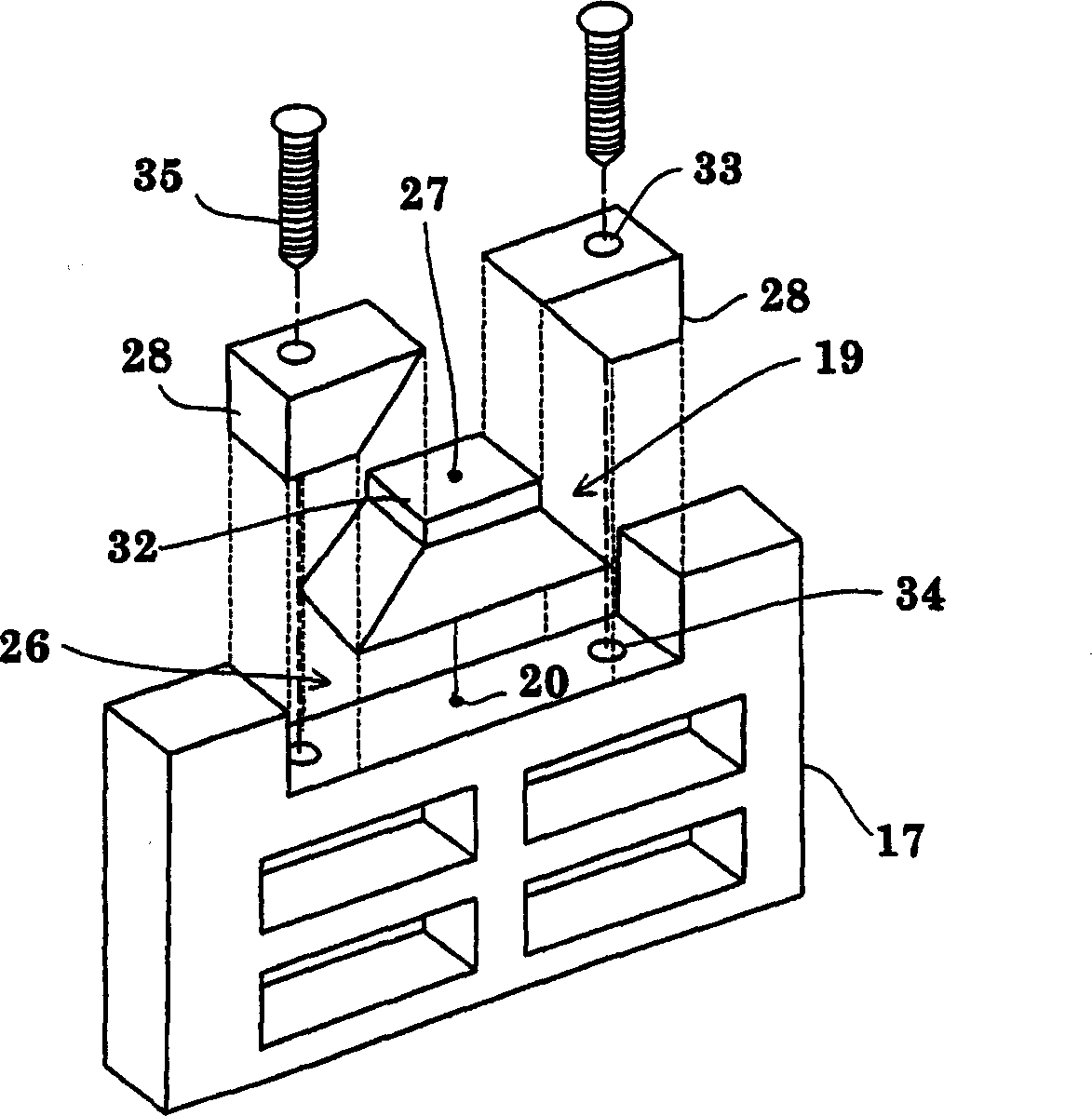

[0047] The ultrasonic bonding device of this embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com