Micro-emulsion with emamectin benzoate and cypermethrin and preparation method thereof

A technology of methylamino abamectin and benzoate, which is applied in the field of the compound insecticide of methylamino abamectin benzoate and cypermethrin, and can solve problems such as unsatisfactory insecticidal effect and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

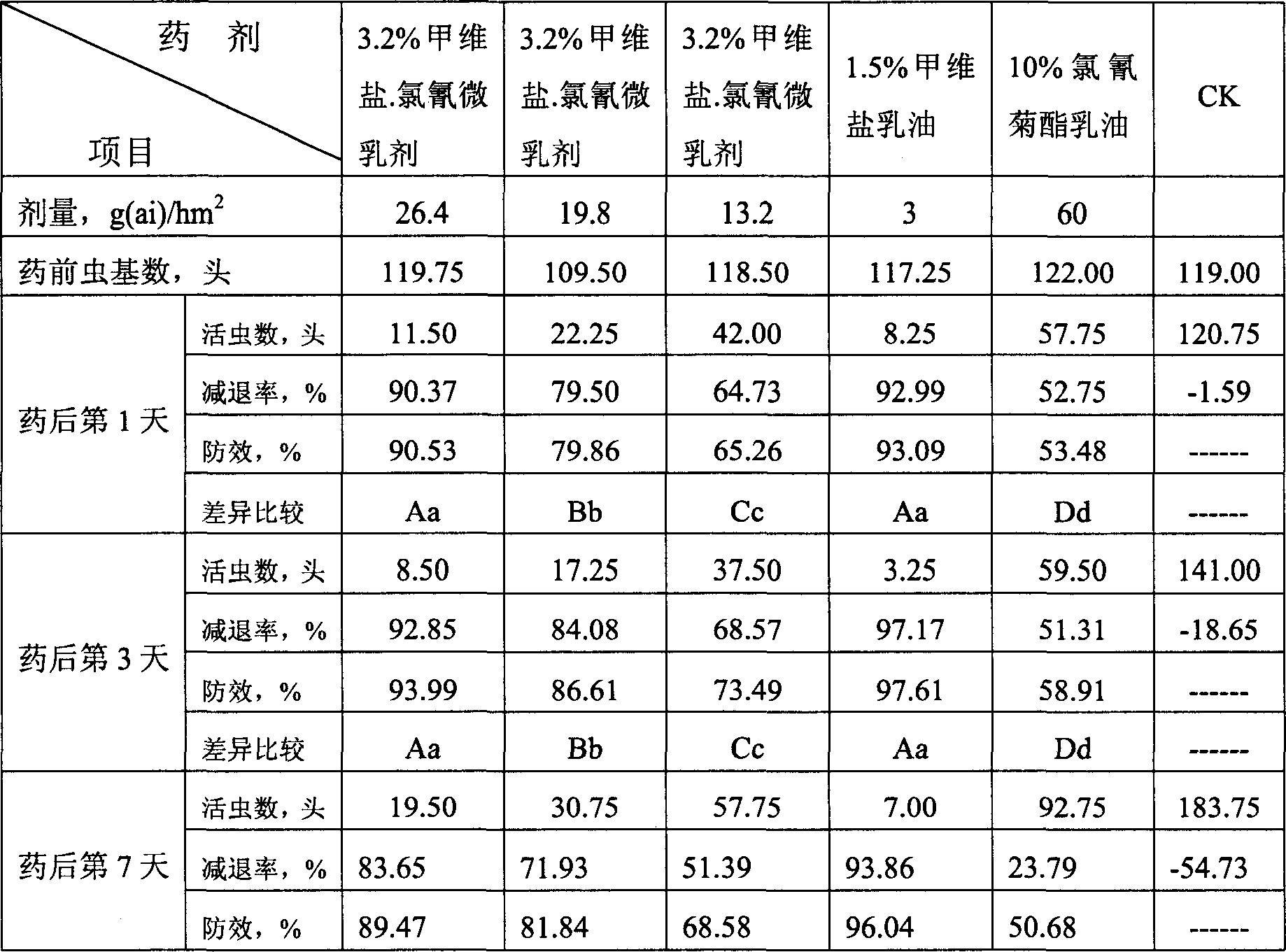

Examples

Embodiment 1

[0025] (1) Raw material ratio: emamectin benzoate 0.01Kg, cypermethrin 0.1Kg, cyclohexanone 10Kg, calcium dodecylbenzenesulfonate 0.1Kg, styrene phenol polyoxyethylene ether 0.1Kg, Alkylphenol formaldehyde resin polyoxyethylene ether 0.1Kg, tap water 89.59Kg.

[0026] (2) Preparation process: Preheat alkylphenol formaldehyde resin polyoxyethylene ether, styrene phenol polyoxyethylene ether, and calcium dodecylbenzenesulfonate to 50°C;

[0027] Drop into cyclohexanone 10kg in reactor, add 0.01kg emamectin benzoate, 0.1kg cypermethrin under stirring state, add calcium dodecylbenzenesulfonate 0.1kg successively after dissolving, styrene phenol polyoxyethylene ether 0.1kg, Alkylphenol formaldehyde resin polyoxyethylene ether 0.1kg, continue to stir evenly. Weigh 85.59kg of water, add it to the above mixture, the temperature is 35°C when mixing, stir for two hours, the materials are mutually soluble;

[0028] When the pH of the mixed solution is determined to be 4, transfer the m...

Embodiment 2

[0030] (1) Raw material ratio: emamectin benzoate 0.1Kg, cypermethrin 0.5Kg, cyclohexanone 12Kg, calcium dodecylbenzenesulfonate 1Kg, styrene phenol polyoxyethylene ether 20Kg, alkyl Phenolic resin polyoxyethylene ether 0.1Kg, tap water 66.3Kg.

[0031] (2) Preparation process: Preheat alkylphenol formaldehyde resin polyoxyethylene ether, styrene phenol polyoxyethylene ether, and calcium dodecylbenzenesulfonate to 50°C;

[0032] Put 12 kg of cyclohexanone into the reaction kettle, add 0.1 kg of emamectin benzoate and 0.5 kg of cypermethrin under stirring state, add 1 kg of calcium dodecylbenzenesulfonate, 20 kg of styrene phenol polyoxyethylene ether, alkyl Phenol formaldehyde resin polyoxyethylene ether 0.1kg, continue to stir evenly. Weigh 66.3kg of water, add it to the above mixture, the temperature is 36°C when mixing, stir for two hours, the materials are mutually soluble;

[0033] When the pH of the mixed solution is determined to be 5, transfer the material to the set...

Embodiment 3

[0035] (1) Raw material ratio: emamectin benzoate 1.5Kg, cypermethrin 5Kg, cyclohexanone 15Kg, calcium dodecylbenzenesulfonate 20Kg, styrene phenol polyoxyethylene ether 5Kg, alkylphenol Formaldehyde resin polyoxyethylene ether 2Kg, tap water 51.5Kg.

[0036] (2) Preparation process: Preheat alkylphenol formaldehyde resin polyoxyethylene ether, styrene phenol polyoxyethylene ether, and calcium dodecylbenzenesulfonate to 55°C;

[0037] Put 15kg of cyclohexanone into the reaction kettle, add 1.5kg emamectin benzoate, 5kg cypermethrin under stirring state, add 20kg of calcium dodecylbenzenesulfonate successively after dissolving, 5kg of styrene phenol polyoxyethylene ether, alkylphenol Formaldehyde resin polyoxyethylene ether 2kg, continue to stir evenly. Weigh 51.5kg of water, add it to the above mixture, the temperature is 38°C when mixing, stir for two hours, the materials are mutually soluble;

[0038] When the pH of the mixed solution is measured to be 6, transfer the mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com