Light emitting device and a method of manufacturing thereof

A technology of a light-emitting device and a manufacturing method, which are applied in the directions of light-emitting materials, lighting devices, electroluminescent light sources, etc., to achieve the effect of improving characteristics and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

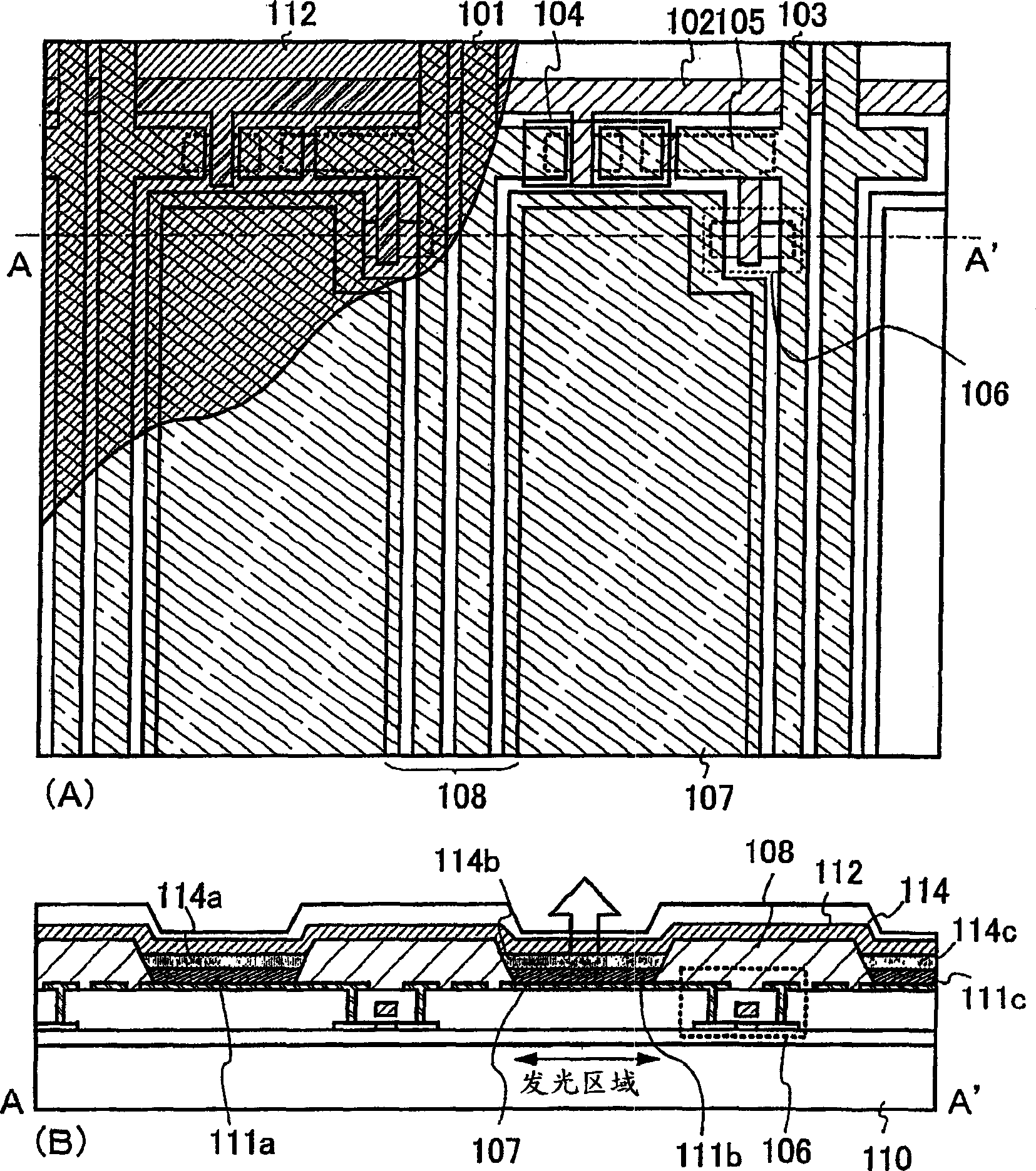

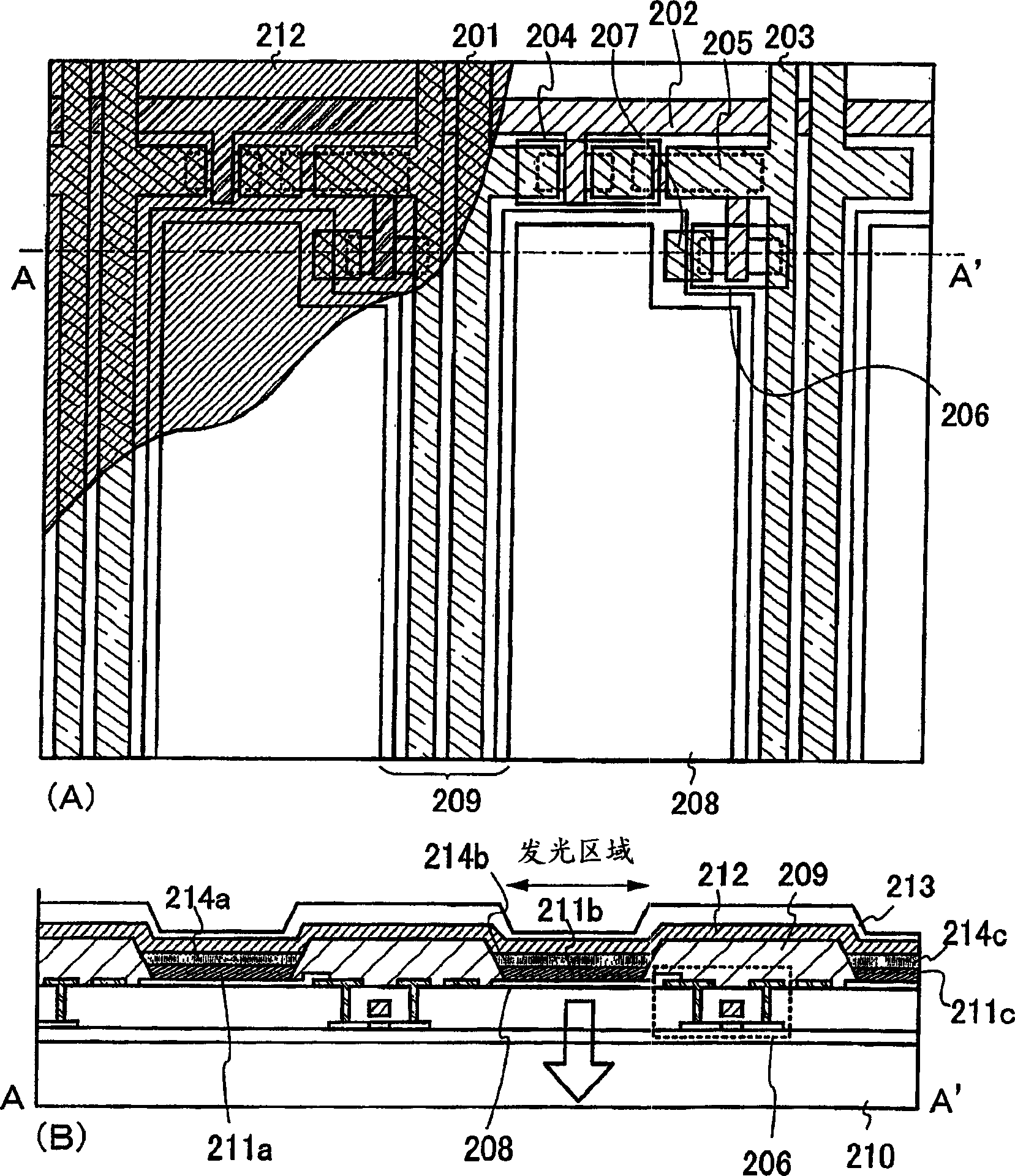

Image

Examples

Embodiment approach 1

[0055] This embodiment mode shows the structure of the above-mentioned conjugated polymer used as a hole injection material. The compound represented by formula (1) is a polythiophene derivative. In order to increase the solubility to organic solvents, the substituent R 1 , R 2 It may be an alkyl group having 4 or more carbon atoms having a linear or branched structure, preferably an aliphatic hydrocarbon group having a linear or branched structure having 4 to 6 carbons, or an alicyclic hydrocarbon group having 4 to 6 carbons. Alternatively, a benzene ring having an aliphatic hydrocarbon group or an alicyclic hydrocarbon group, or a condensed aromatic ring may be introduced. In addition, an electron-deficient heteroaromatic ring such as a pyridine ring or a quinoxaline ring may also be introduced, and an aliphatic hydrocarbon group having 4 or more carbons or an alicyclic hydrocarbon group having 4 to 10 carbons may be introduced into the heteroaromatic ring. The polymers o...

Embodiment approach 2

[0065] Next, an electron-accepting organic compound that oxidizes a conjugated polymer used as a hole injection material described in Embodiment 1, that is, an electron-accepting organic compound that is a dopant doped in the above-mentioned conjugated polymer will be described. . In addition, the doping method thereof will be described.

[0066] Formulas (2) to (9) are examples of electron-accepting organic compounds used to oxidize the above-mentioned conjugated polymers. In order to rapidly oxidize the main chain of the conjugated polymer, it is preferable to use an electron-accepting unsaturated compound or an aromatic compound. In addition, since the solubility in highly polar organic solvents is often improved by doping with a conjugated polymer, it is less necessary to introduce an alkyl side chain or the like into an electron-accepting organic compound. In addition, as the electron-accepting organic compound, a polymer having a side chain introduced by an organic com...

Embodiment approach 3

[0071] In this embodiment mode, a method of laminating each functional layer on a substrate after forming a film of a hole injection material manufactured using the materials and methods described in Embodiment Modes 1 and 2 will be described.

[0072] As the substrate coated with ITO, not only quartz or glass, but also paper, plastic resin, and the like can be used. In addition, a substrate on which TFTs are mounted in advance may also be used. Using the conjugated polymers and electron-accepting organic compounds described in Embodiments 1 and 2, the hole injection material is produced by the method described in Embodiment 1, and at least one hole injection layer is laminated on the substrate.

[0073] The functional layers are then laminated. The functional layer includes, for example, a hole-transporting layer, a light-emitting layer, an electron-transporting layer, an electron-injecting layer, a hole-blocking layer, and an electron-blocking layer. In order to be in conta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com