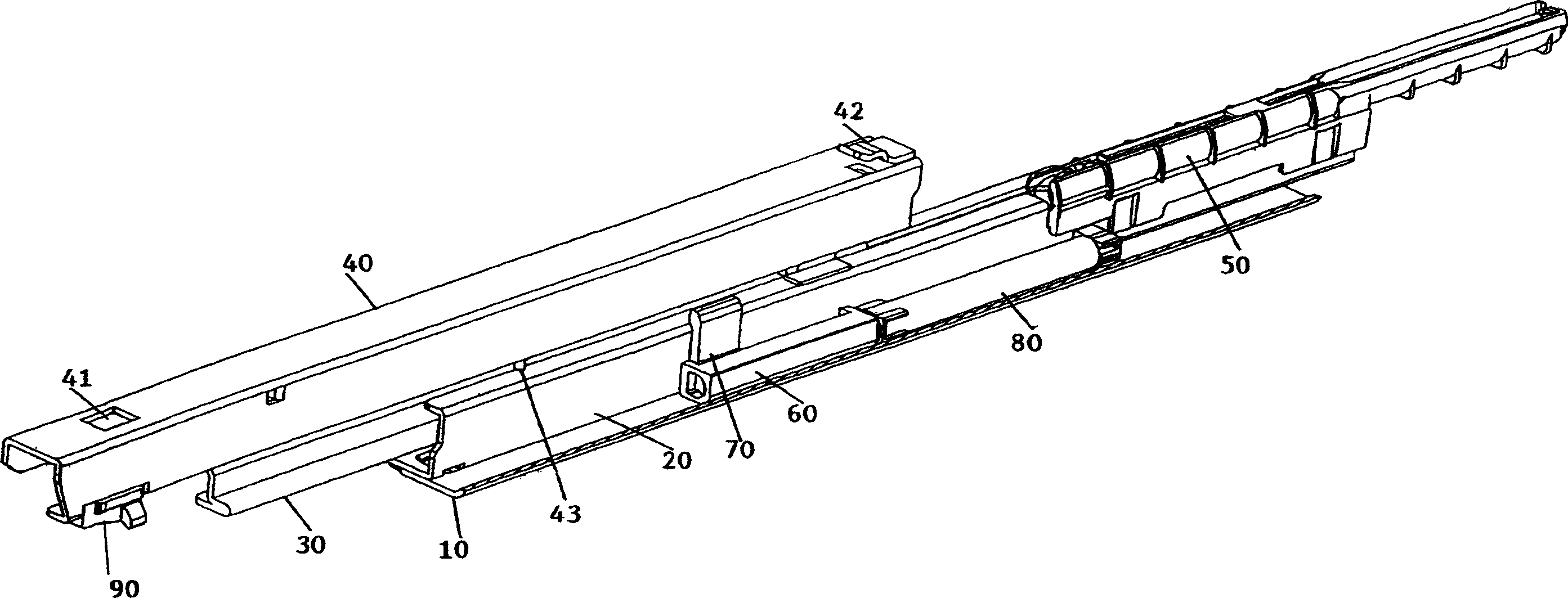

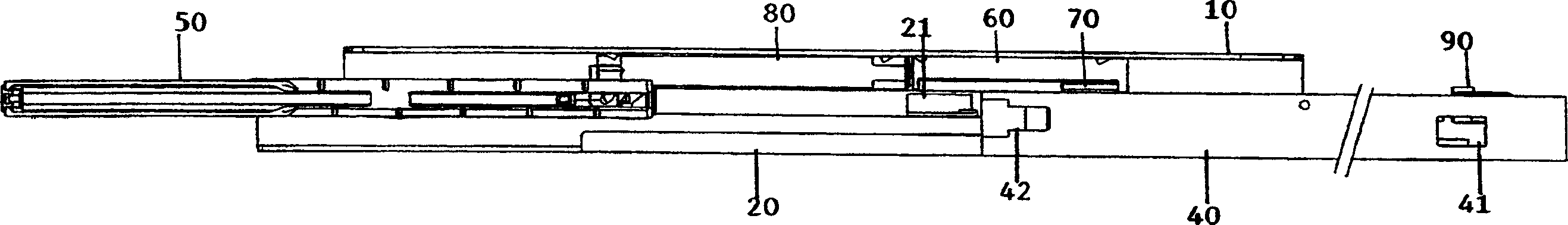

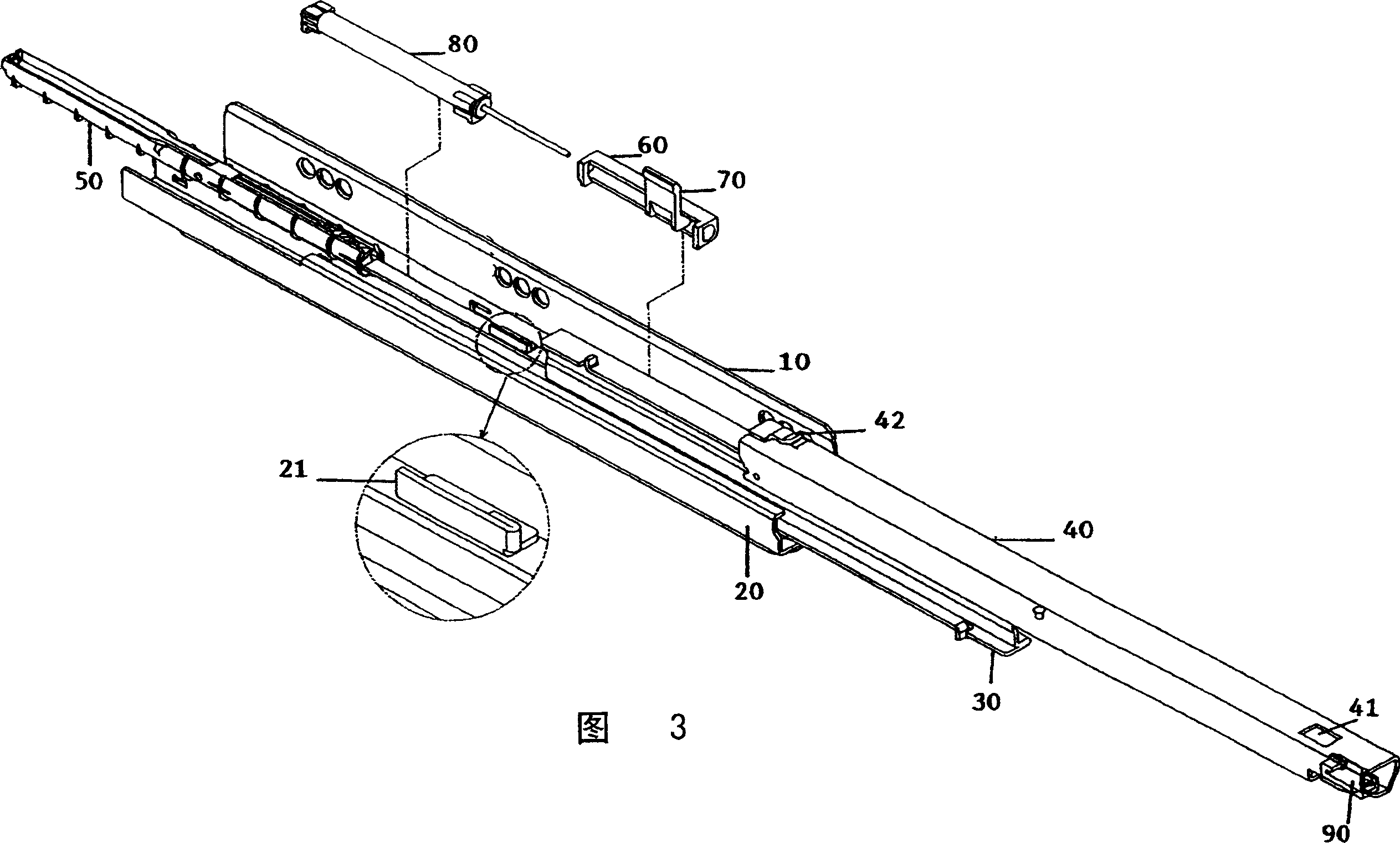

Drawer guide rail assembly

A technology of guiding rails and guides, which is applied in the direction of drawers, furniture parts, household appliances, etc., can solve the problems of decelerating drawer closing force, insufficient compression of linear buffers, inconsistency, etc., to reduce the possibility of damage and prevent impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0065] Again, both the cushioning device 800 and the channel guide 600 with the sliding member 700 are positioned longitudinally end-to-longitudinal end-to-longitudinal with the cushioning device 80 in the rear position and the channel guide 600 in the front position, front and rear The position is relative to the orientation of the drawer within the furniture piece. A pair of openings with holders 114 are provided on the horizontal flange of the L-shaped section to securely hold the channel guide 600 thereon. A similar opening with retainer 117 is also provided with retaining holes 115 and tabs 116 in order to retain the cushioning device 800 on the horizontal flange. In addition, the stopper 121 is also disposed on the horizontal flange of the L-shaped section, and is close to and located between the channel guide 600 and the T-shaped fixed rail 200 . The stop 121 is positioned such that it is in front of the rear travel limit of the slide member 700 within the channel guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com