Sound sucking high elasticity concrete material for road

A technology of elastic concrete and pitch, applied in the field of concrete, can solve the problems of shrinkage joint width, high rigidity, strong vibration, etc., and achieve the effect of improving deformation ability, high elasticity, and reducing road noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following embodiments are provided in conjunction with the contents of the present invention:

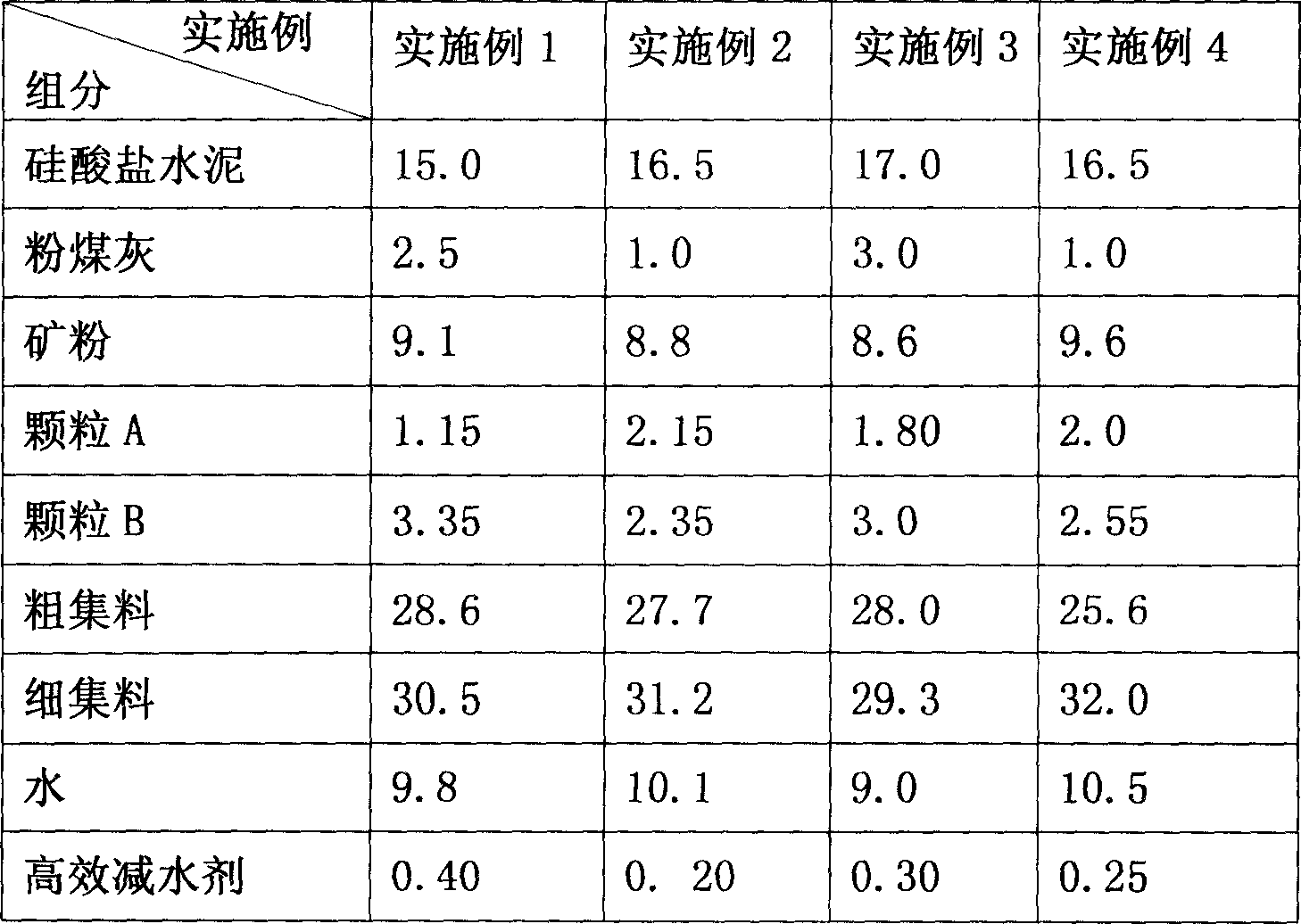

[0020] Road sound-absorbing high-elasticity concrete material is composed of Portland cement, fly ash, calcium carbonate mineral powder, broken rubber tire particles, coarse aggregate, fine aggregate, high-efficiency water reducer and water in a certain proportion, with the following process method Completion: first dry mix cement, fly ash and calcium carbonate mineral powder according to the design requirements of the mix ratio for 1 minute, add 40% water and stir for 2-3 minutes; then add broken rubber tire particles A and B, and stir for 3 minutes ; Then add coarse aggregate and fine aggregate, the stirring time is 15 seconds to 1 minute, and finally add the remaining water dissolved with high-efficiency water reducer, and stir to form a concrete mixture, and the stirring time is 2-3 minutes. Pave the pavement with the well-mixed concrete mixture, and vibrate properly,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com