Glass cutting table

A glass cutting, cutting table technology, applied in glass cutting devices, glass manufacturing equipment, lighting and heating equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

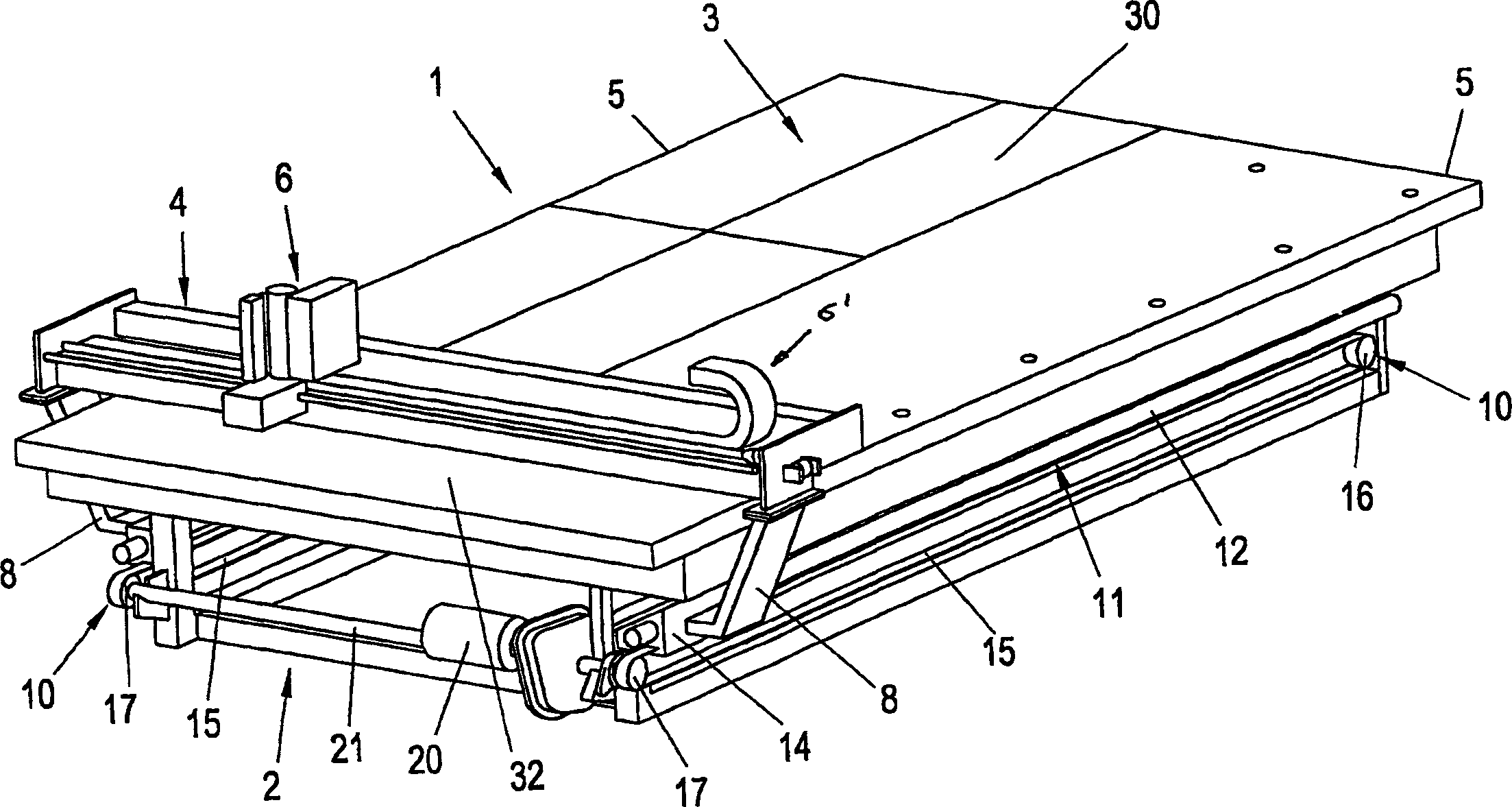

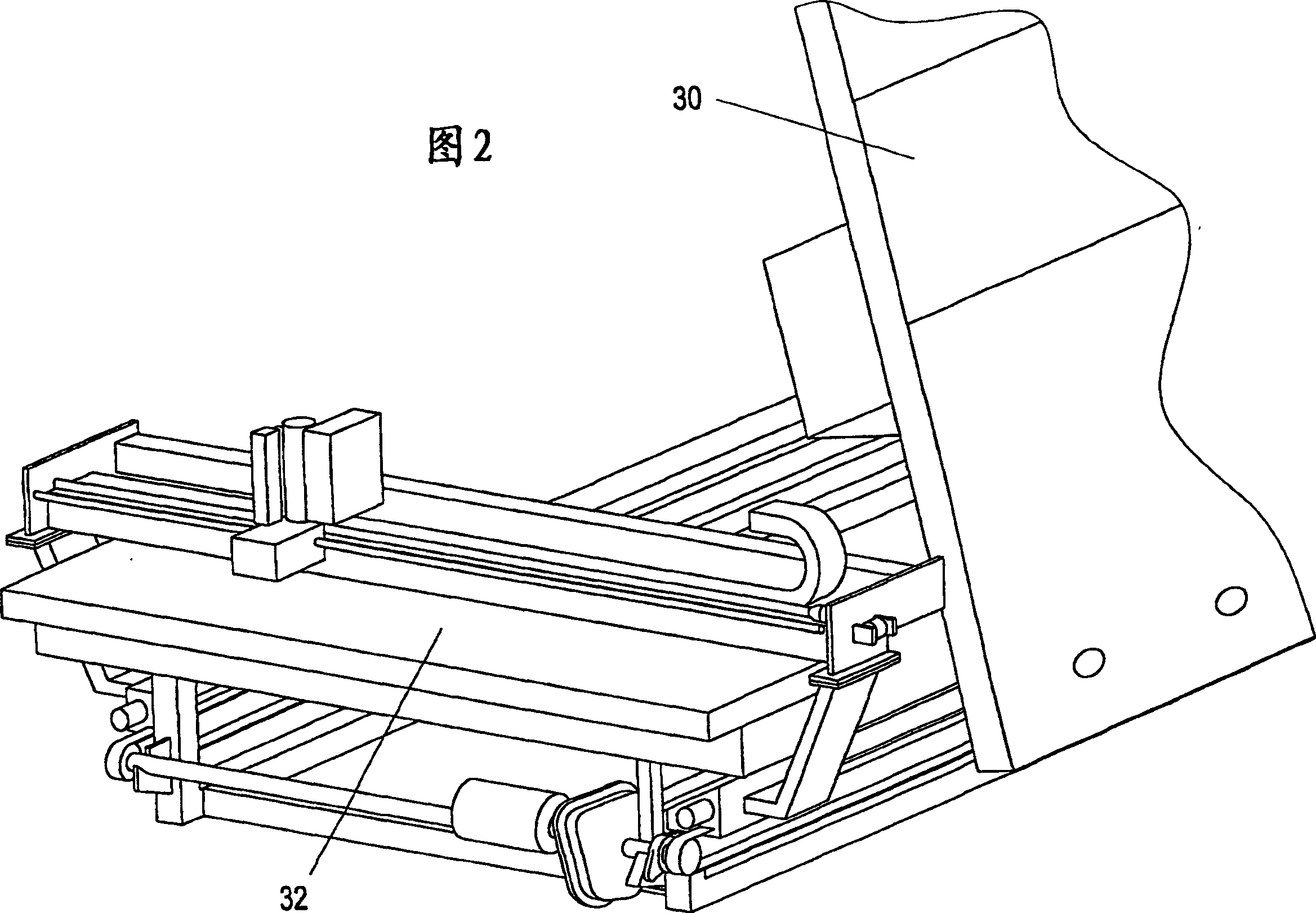

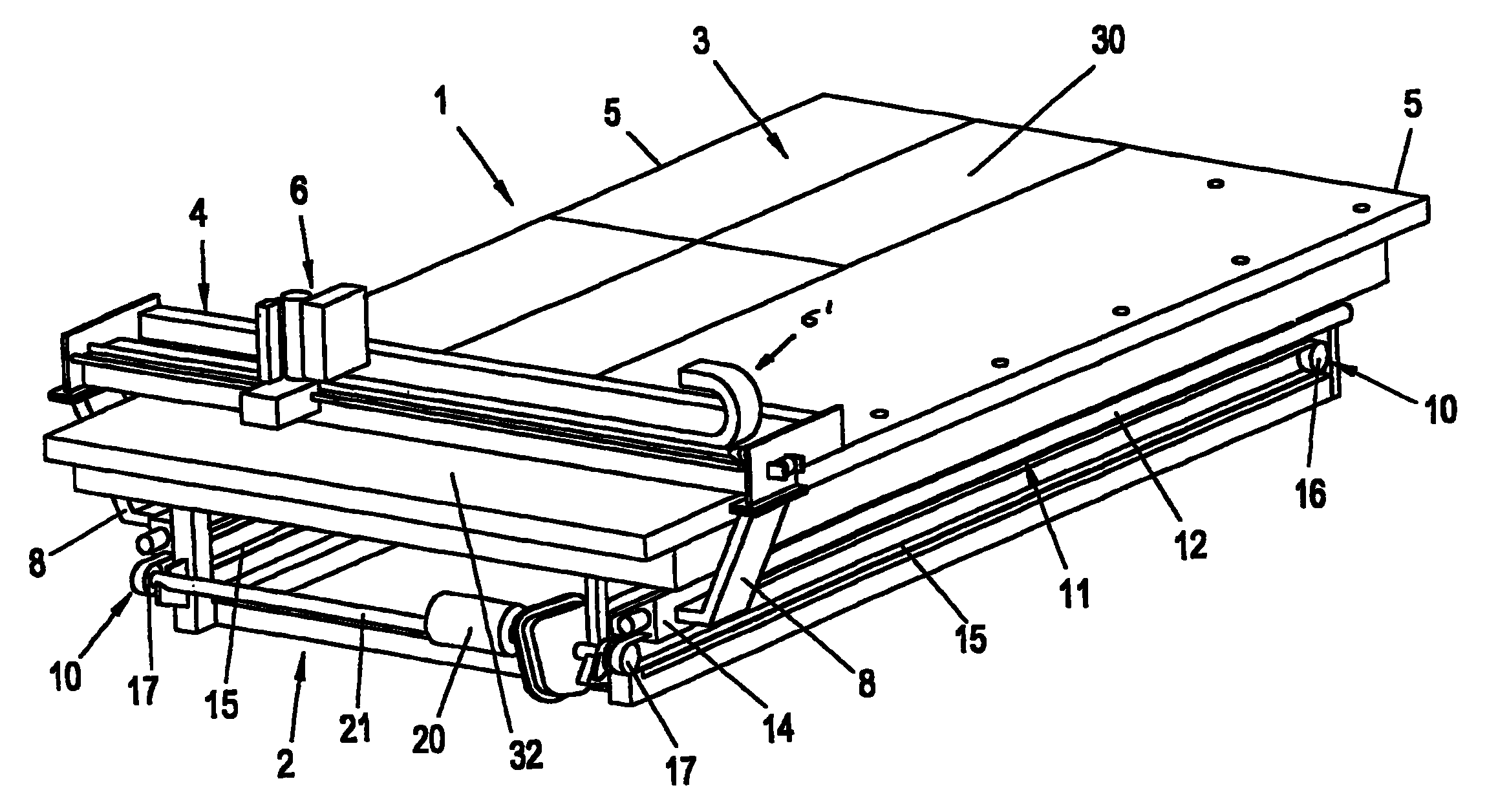

[0019] one in figure 1 The glass cutting table 1 shown in an oblique view in and 2 has a base 2 standing on the ground via feet not shown. The base 2 supports a flat plate 3 (platen), which serves as a support for the glass panes (ribbon-shaped dimensions) to be separated. The flat plate 3 can be equipped with a conveying mechanism not shown for moving and positioning the glass sheets to be separated before and after cutting. Furthermore, the plate 3 has a felt pad, and there is the possibility of constituting the plate 3 as an air-cushioned plate, in which case there are patterned air outlet holes in the plate 3 for delivery to these The compressed air in the opening thus forms an air cushion between the flat plate 3 forming the carrier and a glass plate, which reduces the friction between the glass plate and the carrier 3 .

[0020] The plate 3 is mostly rectangular. A cutting bridge 4 is provided parallel to the shorter side of the plate 3 as a support. The cutting brid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com