Intersia pattern shuttle box for flat-bed knitting machine

A technology of flat knitting machine and shuttle box, which is applied in weft knitting, knitting, textiles and papermaking, etc. It can solve the problems of the influence of yarn feeder positioning accuracy, increased idle travel of the machine head, and difficulty in reaching the guide surface, etc., to achieve locking and The loosening action is light and labor-saving, the knitting efficiency is improved, and the effect of locking and positioning is precise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

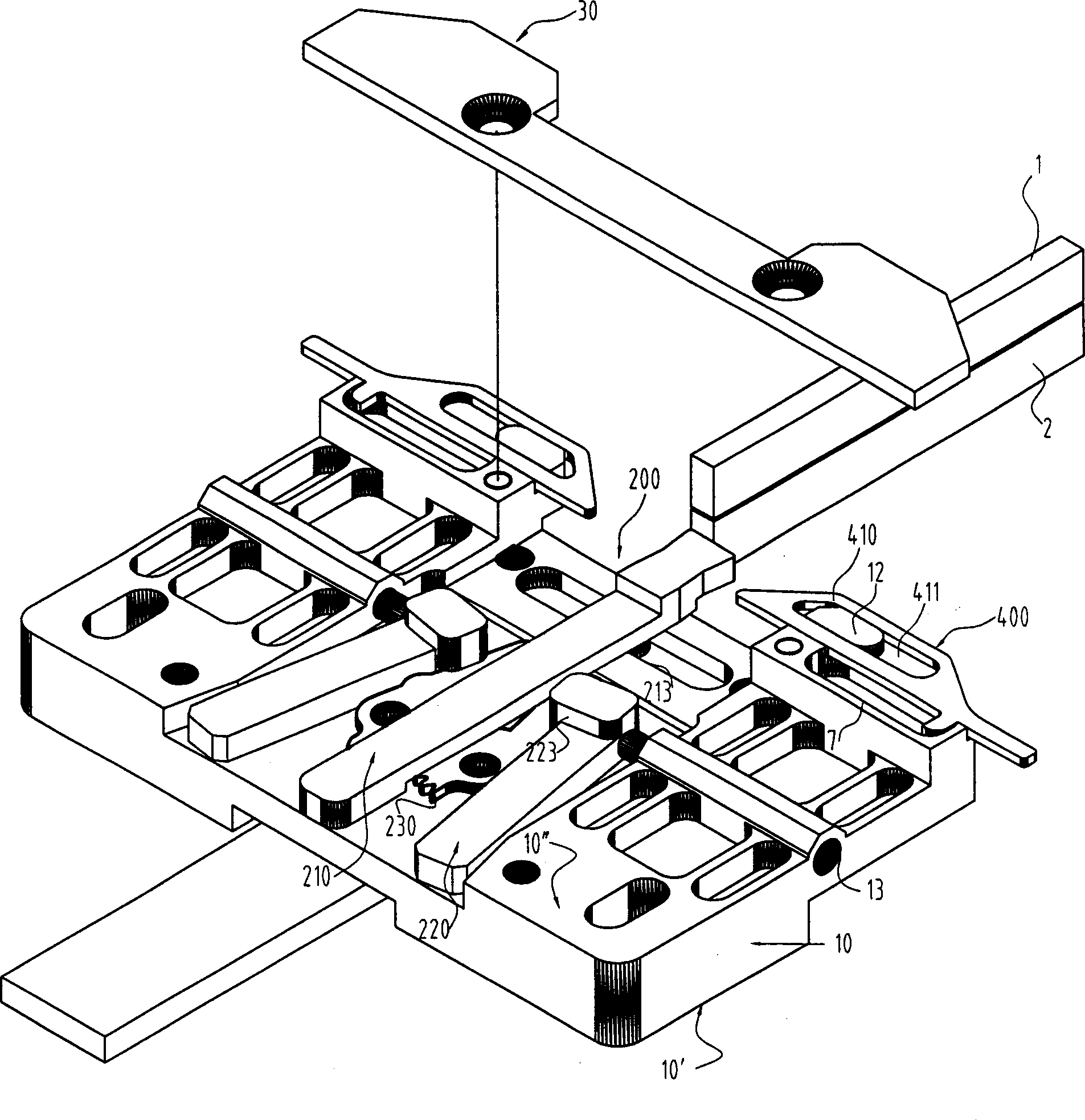

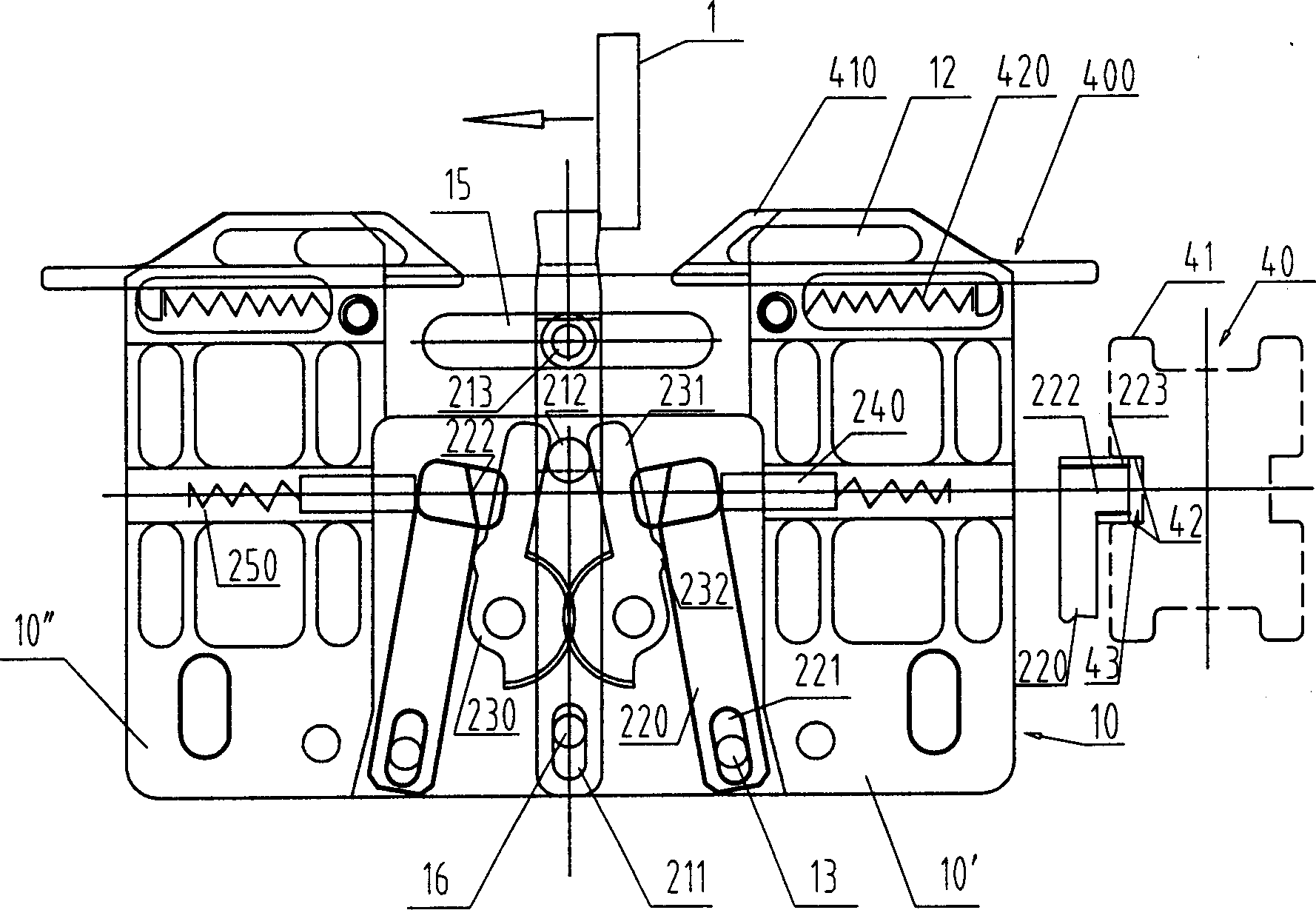

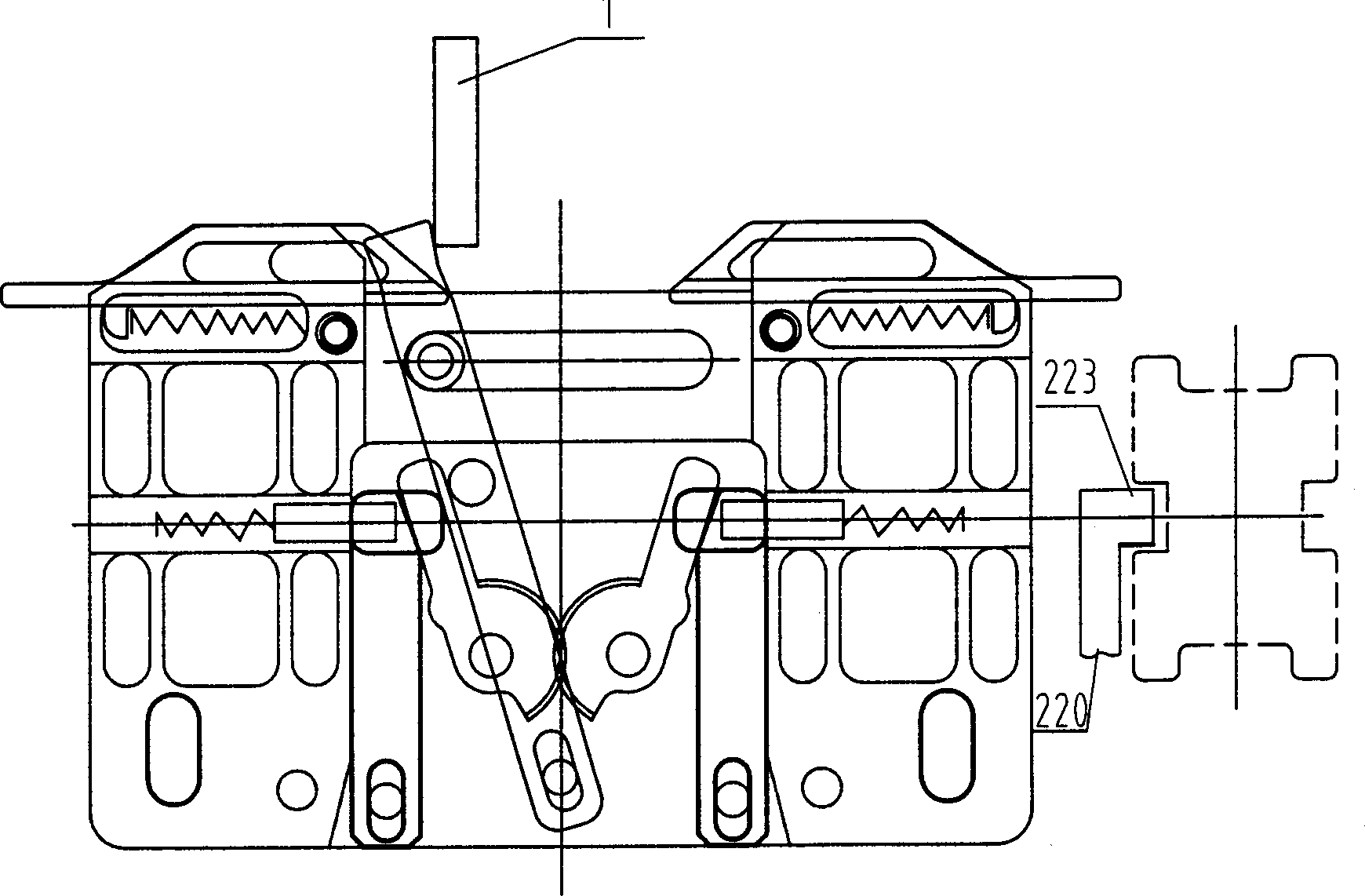

[0031] The intarsia shuttle box of the present invention consists of a box body 10 , an outer cover plate 20 , an inner cover plate 30 , an anti-collision device 400 , a locking mechanism 200 , a yarn feeder moving device 100 and a limit mechanism 260 . Wherein the anti-collision device 400 and the locking mechanism 200 are placed in the inner side of the box body, and they are respectively placed in the upper end and the middle part of the inner side 10' of the box body, please refer to figure 1 and figure 2 or image 3 .

[0032] The locking mechanism 200 is composed of two locking pins 240 , two locking pin return springs 250 , two locking levers 220 , a transmission lever 210 and a pair of incomplete gears 230 . Each locking pin 240 and the corresponding locking pin return spring 250 are placed in the corresponding hole 13 in the middle part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com