Eccentric type control device

A control device, eccentric technology, applied in hoisting device, spring mechanism, etc., can solve the problems of high price, low action sensitivity, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

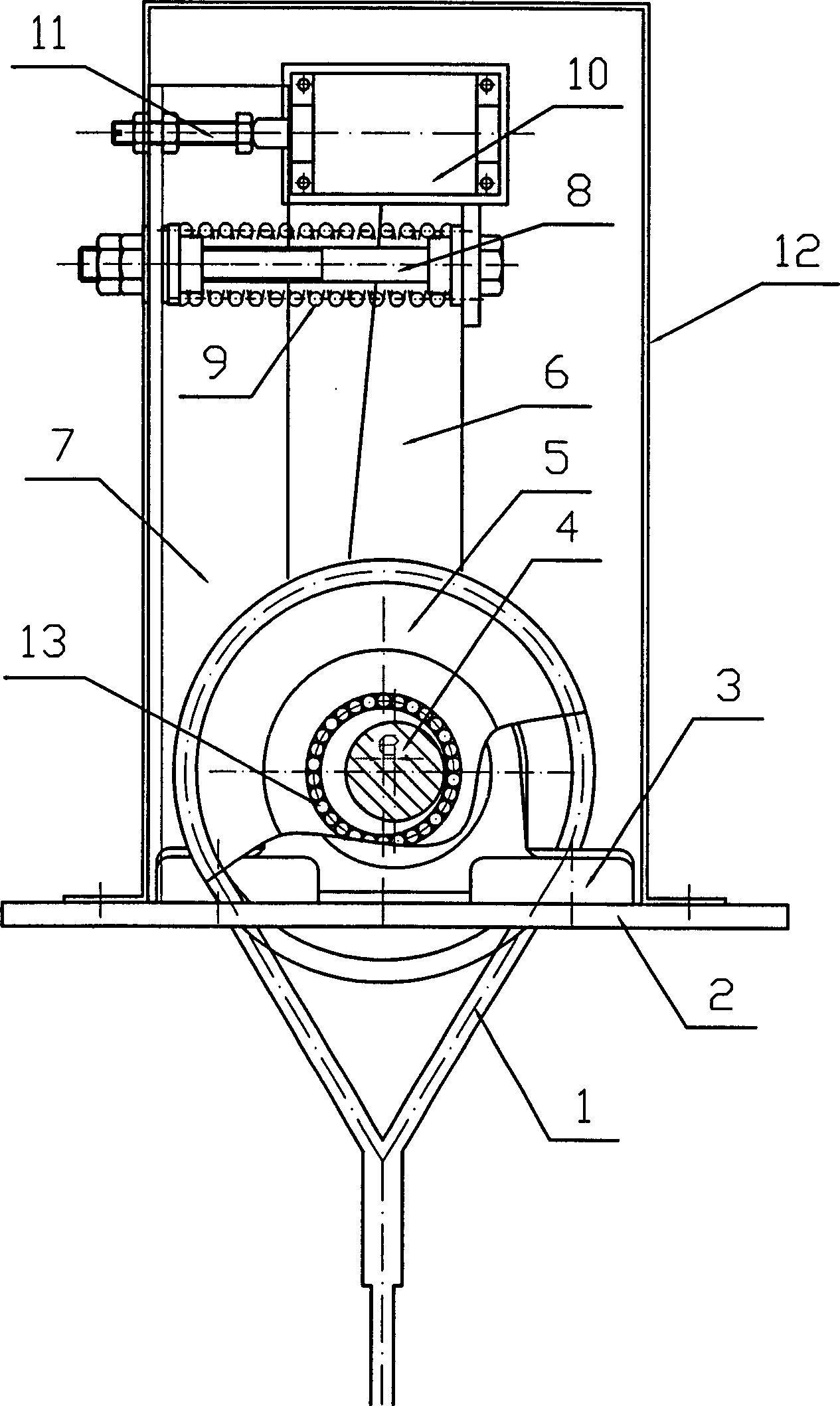

[0014] see figure 1 , Embodiment 1 provides an eccentric wire rope overload protection device, which is provided with a wire rope 1, a plate base 2, an eccentric shaft bearing seat 3, an eccentric shaft 4, a pulley 5, a bearing 13, a swing arm 6, an angle iron Bearing 7, spring seat 8, spring 9, travel switch 10, adjusting bolt 11 and outer cover 12. The steel wire rope 1 is set on the pulley 5, the eccentric shaft bearing seat 3 is installed on the base 2, the two ends of the eccentric shaft 4 are connected to the eccentric shaft bearing seat 3, the pulley 5 is installed on the eccentric shaft 4 through the needle bearing 13, and the swing arm 6 One end is connected to the eccentric shaft 4, the displacement signal detector adopts a travel switch 10, the travel switch 10 and the spring seat 8 are arranged at the other end of the swing arm 6, the other end of the spring seat 8 passes through the upper part of the support 7, and the spring 9 is sleeved on the The middle part o...

Embodiment 2

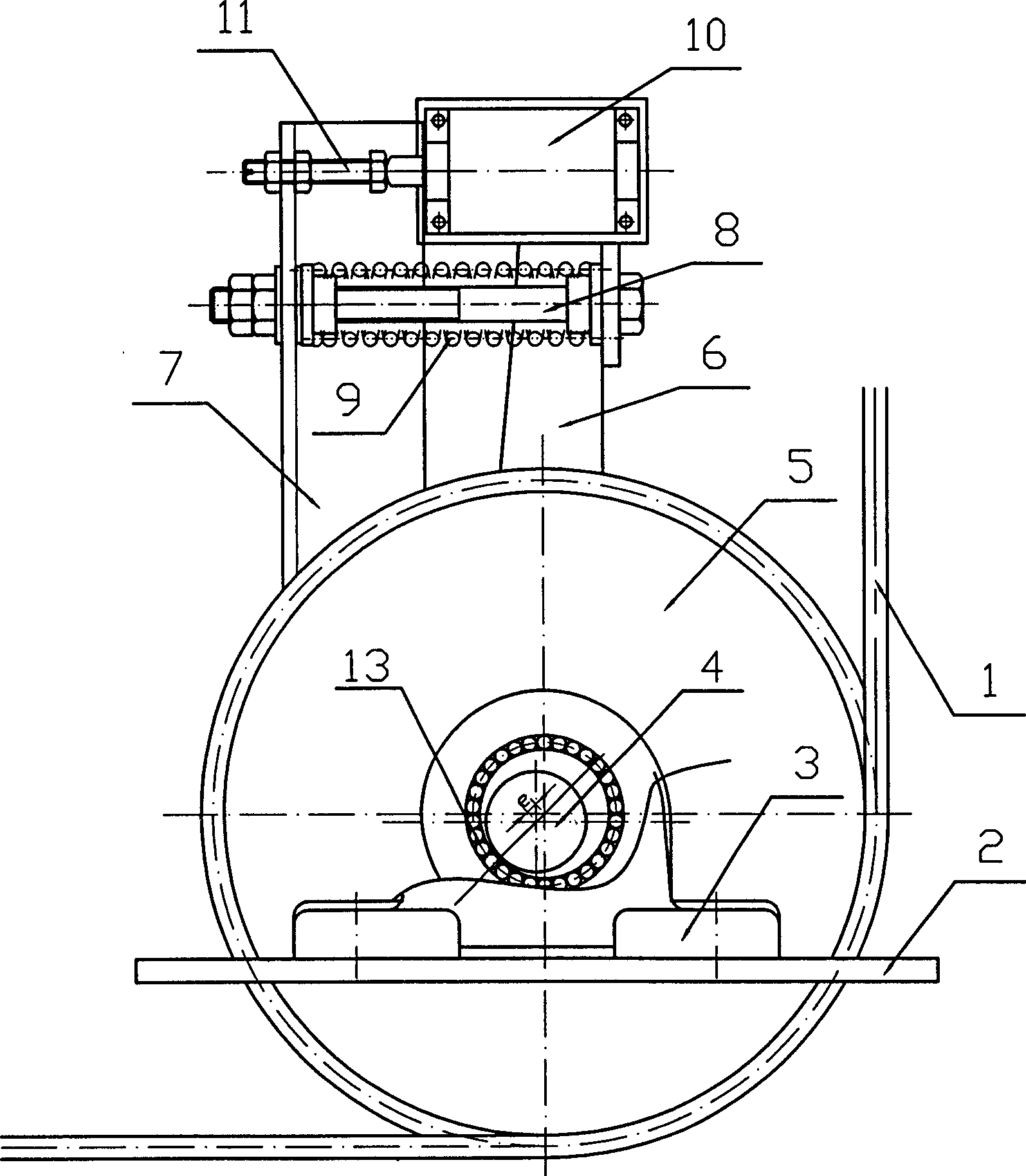

[0018] see figure 2 , Similar to Example 1, the difference is that Example 1 is a vertical structure, while Example 2 adopts a horizontal structure. exist figure 2 The parts or accessories represented by the marks in the figure 1 same.

Embodiment 3

[0020] see figure 1 , similar to Embodiment 1, the difference is that the travel switch 10 adopts an electromechanical sensor breaker, the electromechanical sensor breaker and the bolt 8 are arranged at the other end of the swing arm 6, and the electromechanical sensor breaker is connected to one end of the adjusting bolt 11, The other end of the adjusting bolt 11 is installed on the upper part of the support 7 , and the contact distance between the electromechanical sensor breaker and the support 7 can be changed by adjusting the adjusting bolt 11 . As a control signal, the detection signal output by the electromechanical sensor breaker can be externally connected to other control devices or equipment. The electromechanical sensor breaker can be a commercially available product, or it can be manufactured as required.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com