Adult incontinence pants supersonic welding device and welding method

A technology of ultrasonic welding and adult incontinence pants, which is applied in clothing, underwear, baby underwear, etc., can solve the problems of inability to weld adult incontinence pants and cannot produce adult incontinence pants, achieve continuous and orderly welding, and solve welding strength Not enough, the effect of solving welding problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

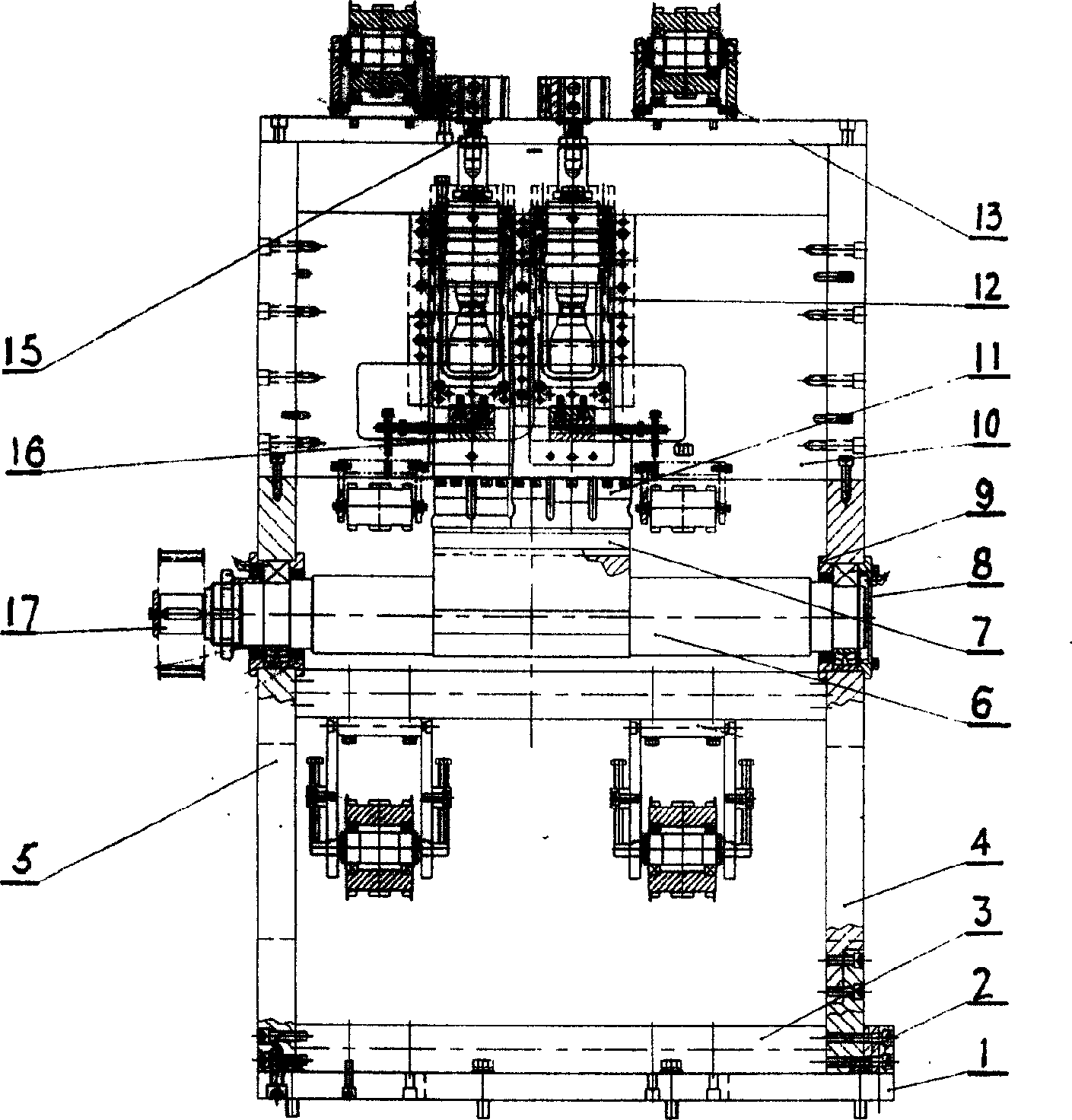

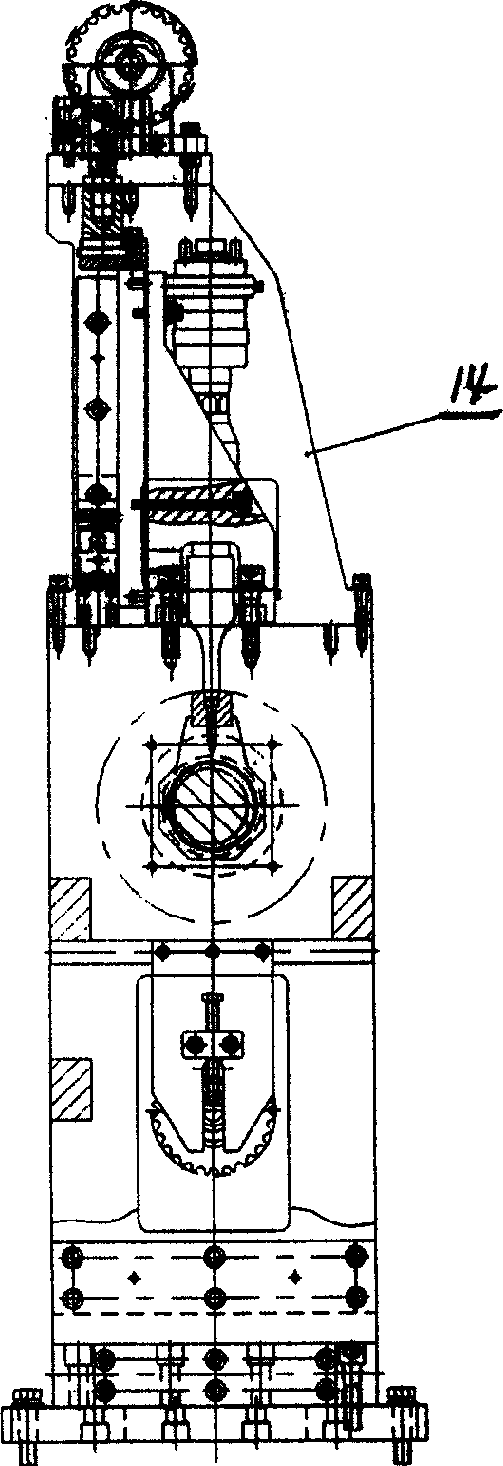

[0010] Embodiment 1: with reference to attached figure 1 and 2 . Ultrasonic welding device for adult incontinence pants, the embossed shaft 6 is processed and formed by the existing technology and the bearing seats, bearings or bearings are located in the shaft holes of the side box plates 4 and 5, the outer bearing caps 8 and 9, and the inner bearing cap 10 are respectively located on the two sides. On the inner and outer sides of the bearing, the transmission wheel 17 is set back on one end of the embossed shaft 6; the embossed block 7 is fixed on the embossed shaft 6, the upper fixed plate 10 is located on the side box plates 4 and 5, and the long distance rod 3 passes through Connecting plate 2, screw are connected on the inboard of side box plate 4 and 5 lower ends, and base plate 1 is fixed on the end face of side box plate 4 and 5 lower ends. Guide rail 12 is vertically fixed on the upper fixed plate 10, and the slide frame is positioned on the guide rail or in the sl...

Embodiment 2

[0011] Embodiment 2: On the basis of Embodiment 1, the adult incontinence pants ultrasonic welding welding method, the embossing shaft drives the embossing block to rotate under the drive of the transmission wheel, and when the embossing block and the ultrasonic die overlap, the cylinder passes through The sliding frame and the ultrasonic die head can pressurize and weld the upper and lower adult incontinence trousers or the upper and lower materials between the embossing block and the ultrasonic die head.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com