Method for testing airtightness of bipolar plate material and special clamp therefor

A test method and technology of bipolar plates, which are used in liquid/vacuum measurement for liquid tightness, and by measuring the acceleration and deceleration rates of fluids. Problems such as poor sex, to achieve the effect of convenient testing, objective and accurate comparison, and convenient testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: a kind of testing method of the airtightness of bipolar plate material, this method comprises the following steps:

[0022] (1) Use the bipolar plate material to be tested to make the same batch of flat plates with a circular shape and a thickness of 5mm;

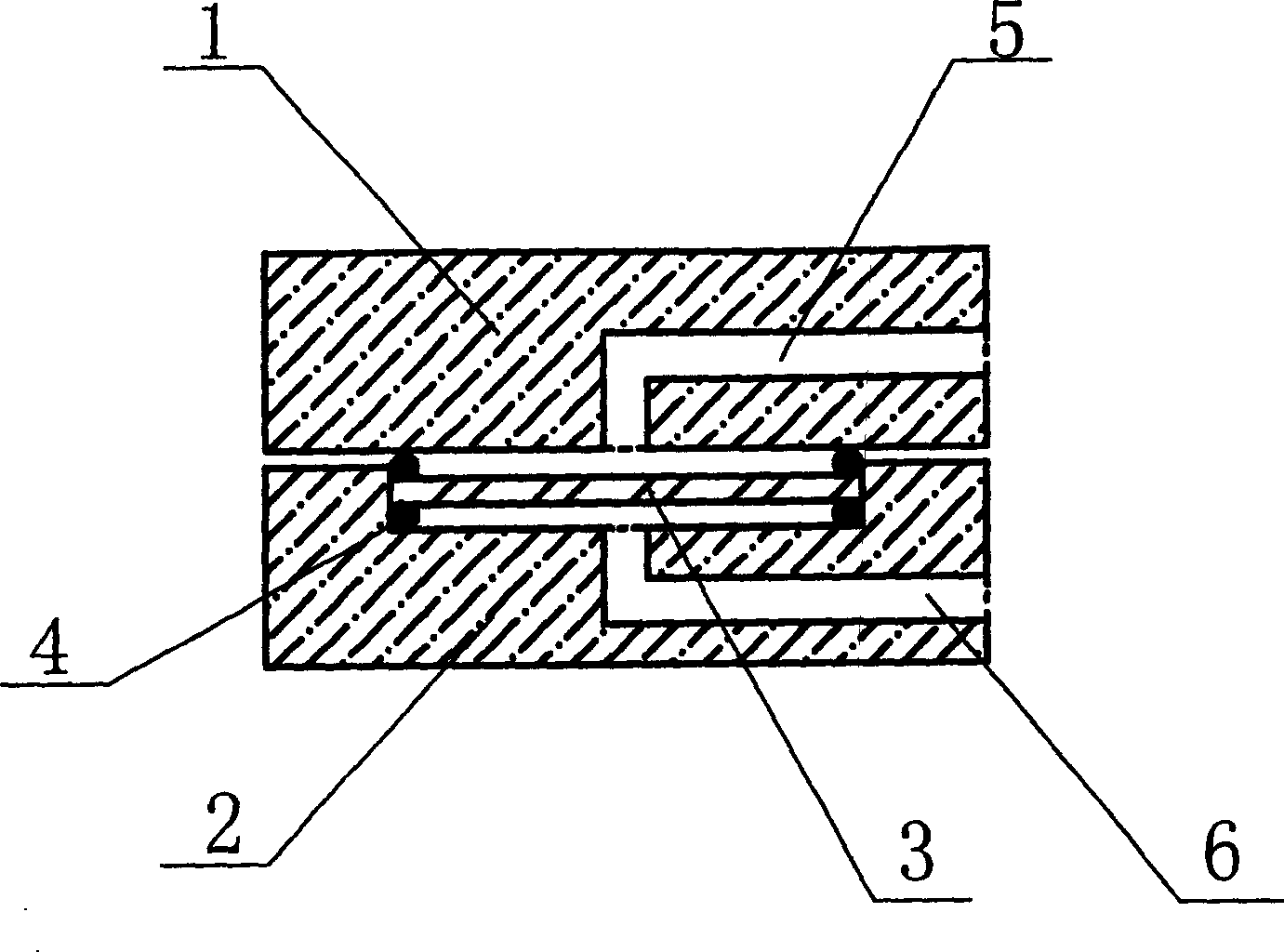

[0023] (2) Prepare a pair of fixtures according to the structural shape of the plate, and the side of the fixture corresponding to the plate is provided with an air flow channel, and the other side is provided with a test channel;

[0024] (3) Use a clamp to clamp the flat plate;

[0025] (4) Inject air with a pressure of 0.2MPa into the airflow channel of the fixture;

[0026] (5) Use a gas flow meter to measure the flow rate of the escaping gas in the test channel of the fixture, and determine the airtight performance of the bipolar plate material according to the difference in flow rate.

Embodiment 2

[0027] Embodiment 2: a kind of testing method of bipolar plate material airtightness, this method comprises the following steps:

[0028] (1) Use the bipolar plate material to be tested to make the same batch of flat plates with a quadrilateral shape and a thickness of 8 mm;

[0029] (2) Prepare a pair of fixtures according to the structural shape of the plate, and the side of the fixture corresponding to the plate is provided with an air flow channel, and the other side is provided with a test channel;

[0030] (3) Use a clamp to clamp the flat plate;

[0031] (4) Inject nitrogen with a pressure of 0.4 MPa into the air flow channel of the fixture;

[0032] (5) Use a gas flow meter to measure the flow rate of the escaping gas in the test channel of the fixture, and determine the airtight performance of the bipolar plate material according to the difference in flow rate.

[0033] In order to realize above-mentioned testing method, the present invention also provides a kind of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com