Oil-containing dross dehydration process

A process and technology of scum, which is applied in the field of oily scum dehydration process, can solve the problems of high operating cost, difficult scum treatment, and secondary pollution of the environment, so as to reduce post-treatment costs, improve scum dehydration rate, and reduce dehydration. Effect of Post Moisture Content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

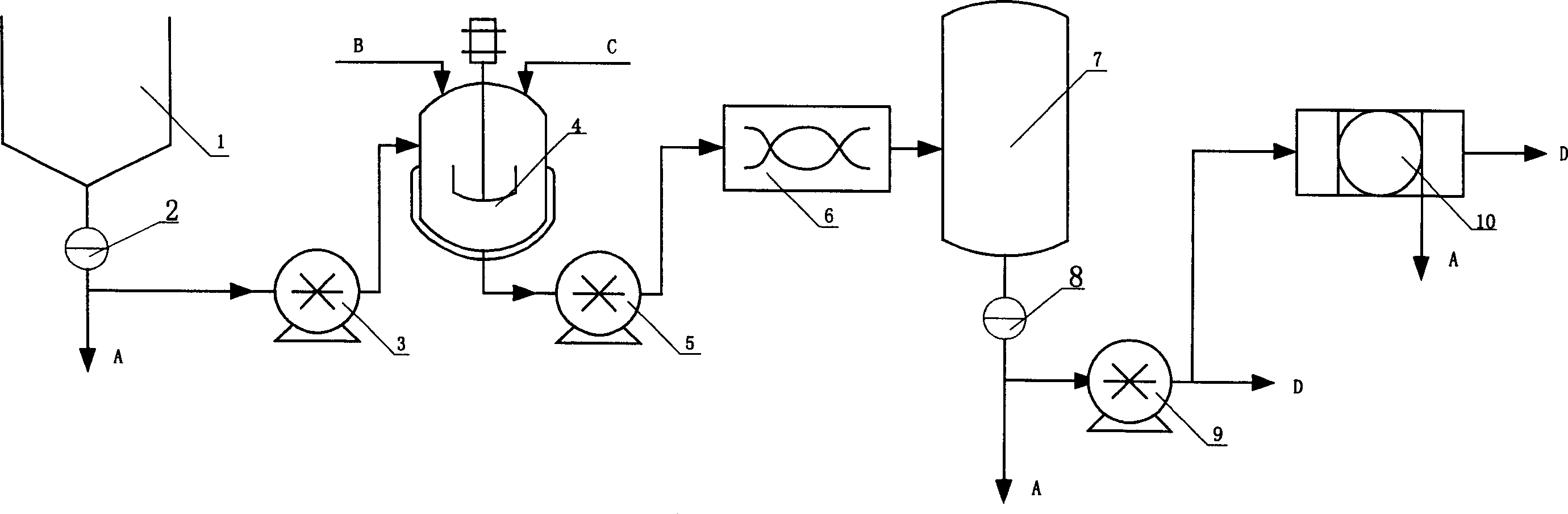

Image

Examples

Embodiment

[0022] (1) The moisture content of primary sedimentation scum in a refinery is 95.0%, and Na 2 CO 3 The pH value was adjusted to 7.1, and the amount of polyaluminum ferric chloride and polyacrylamide added was 75mg·L respectively -1 with 750mg·L -1 , 20kHz ultrasonic wave for 5 minutes, the sound intensity is 500W·m -2 , After suction filtration, the moisture content of the scum is 49.2%, and the dehydration rate reaches 94.9%.

[0023] (2) The moisture content of the primary sedimentation scum in a refinery is 83.8%, and the water content is 83.8% with Na 2 CO 3 The pH value was adjusted to 7.2, and the amount of polyaluminum ferric chloride and polyacrylamide added was 70mg·L respectively -1 with 500mg·L -1 , 28kHz ultrasonic wave for 10 minutes, the sound intensity is 480W·m -2 , after suction filtration, the moisture content of the scum is 54.7%, and the dehydration rate reaches 84.0%.

[0024] (3) The moisture content of primary sedimentation scum in a refinery is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com