Side chain conveying device

A chain conveying and circular conveying technology, applied in the field of logistics, can solve the problems of low replenishment efficiency and high labor intensity, and achieve the effects of high replenishment efficiency, lower manufacturing precision requirements, and stable installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

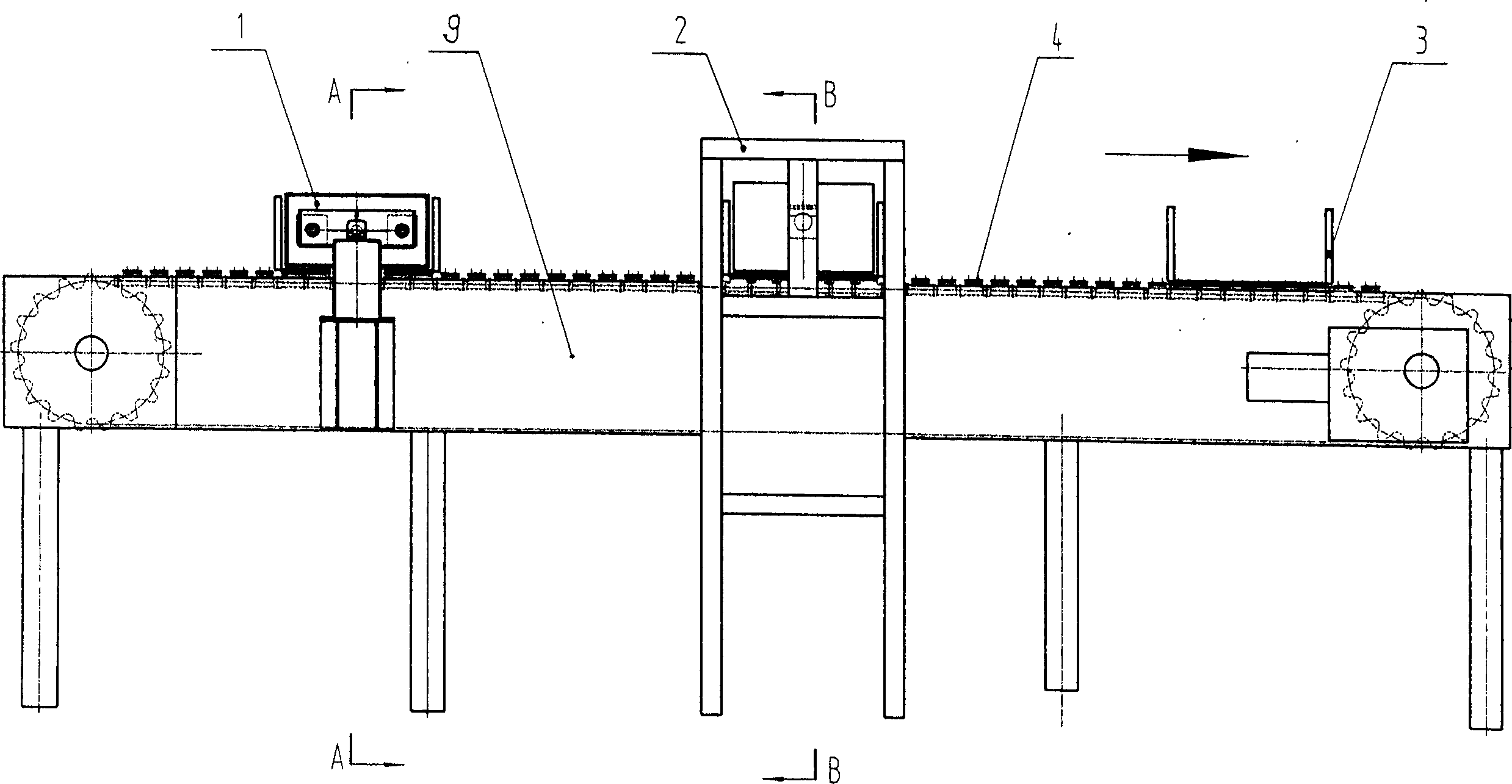

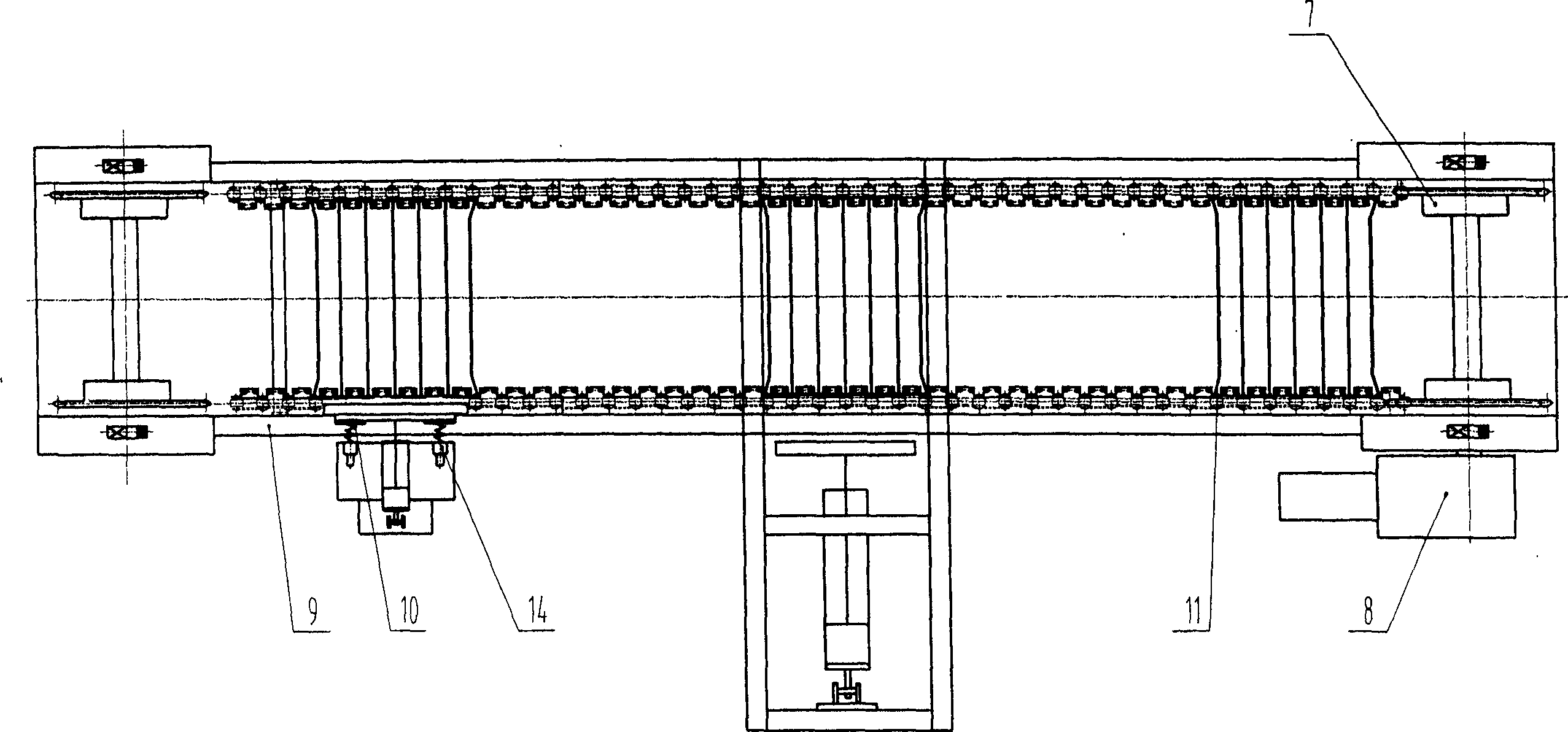

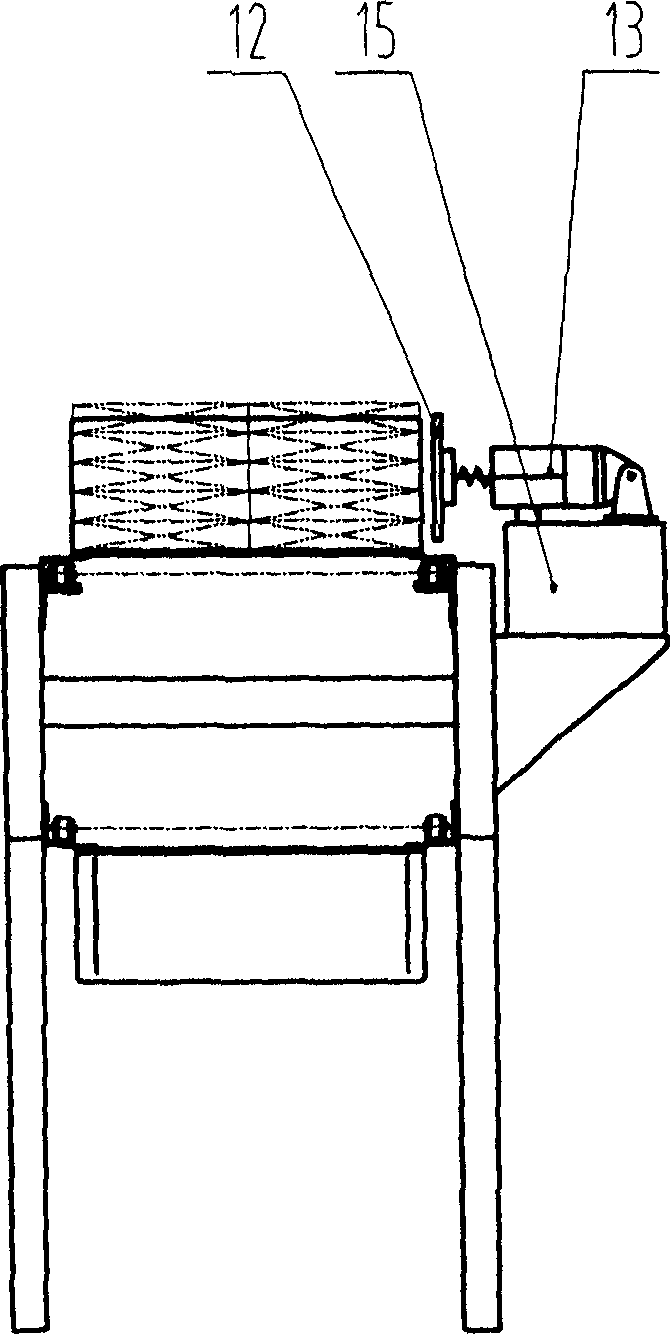

[0015] As shown in the figure, the present invention mainly includes the endless conveyor chain 4 installed on the frame 9, the U-shaped trough 3 with the guide port 11 installed on the endless conveyor chain at intervals, and the shaping mechanism installed in sequence next to the endless conveyor chain 1 and pushing mechanism 2. A support rail 5 and a pressing rail 6 are installed on the frame, respectively supporting and pressing down the endless conveyor chain 4 installed therebetween. The trough 3 is connected with the endless conveyor chain 4 through a transverse waist-shaped hole along the chain length direction. Shaping mechanism 1 includes support 15 and electric or pneumatic drive mechanism 13 installed on the support, the drive mechanism of the present embodiment is a cylinder, the push rod stretched out of the cylinder is connected in the middle of push plate 12, between push plate and support A pair of slide pairs 14 are installed symmetrically on both sides of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com