Small scale singeing machine for textile

A technology of singeing machine and frequency conversion motor, which is applied in singeing, textile and papermaking, fabric surface trimming and other directions, can solve few problems and achieve the effect of good effect, simple and convenient operation and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

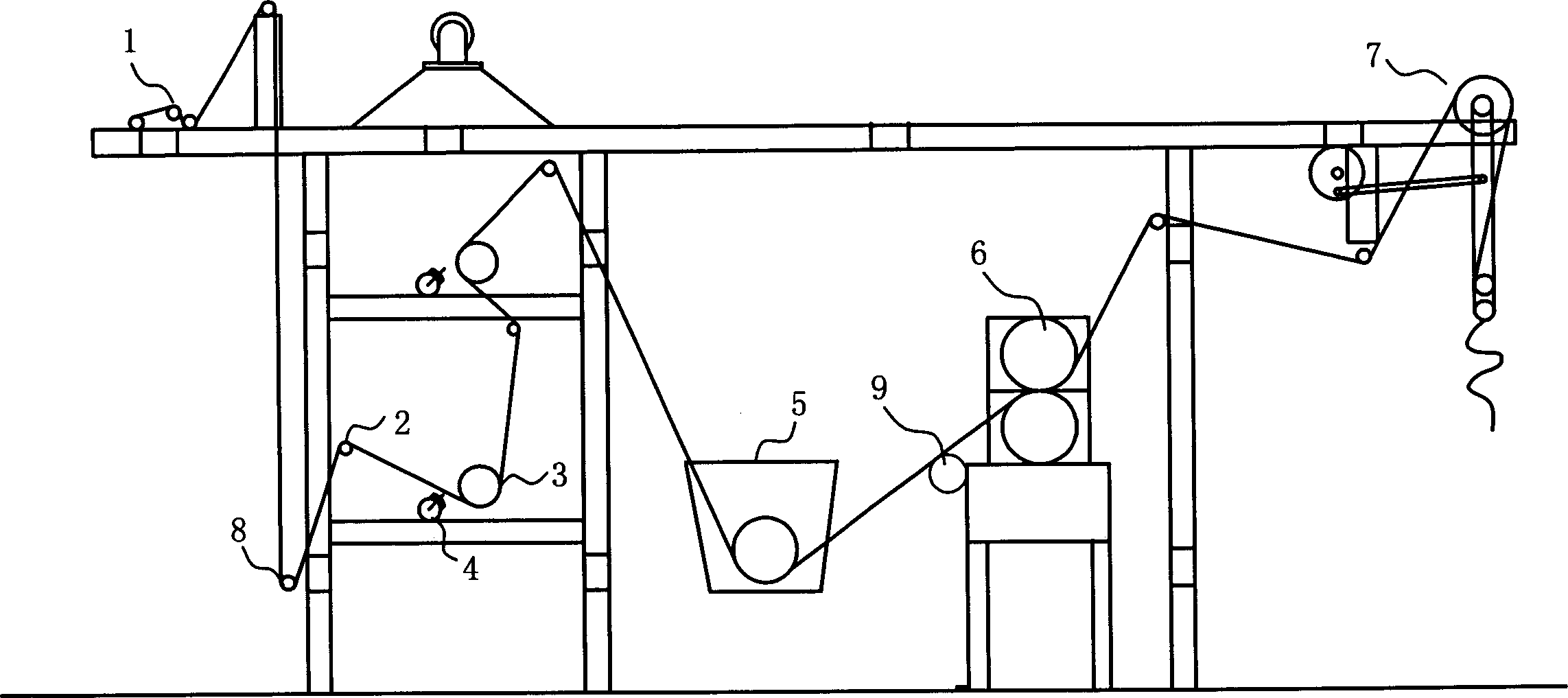

[0007] See attached figure 1 As shown, this embodiment consists of a distribution box, two frequency conversion motors, a cloth feeding tension roller 1, a front tenter roller 2, a rear tenter roller 9, two cooling rollers 3, two fire outlets 4, a fire extinguishing tank 5, Air pressure cloth roller 6, smoke exhaust machine, left and right cloth drop device 7, combustion agent atomization device such as liquefied gas or gasoline, and steam pressure generating device are composed of main parts, in which the distribution box is connected with two frequency conversion motors, and the main motor drives The air pressure pressure roller 6, the auxiliary motor drives the cloth drop left and right rollers 7, the cooling roller 3 is connected with the cooling water supply device, the liquefied gas or gasoline combustion agent atomization gas supply device is connected with the fire outlet 4, the fire extinguishing tank 5 is connected with the water inlet pipe, There is a cloth guide ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com