Liquid crystal display device, manufacturing method and electronic apparatus

A liquid crystal display device and display area technology, applied in transistors, static indicators, optics, etc., can solve problems such as poor display and decreased contrast display characteristics, and achieve the effect of improving display characteristics and reducing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

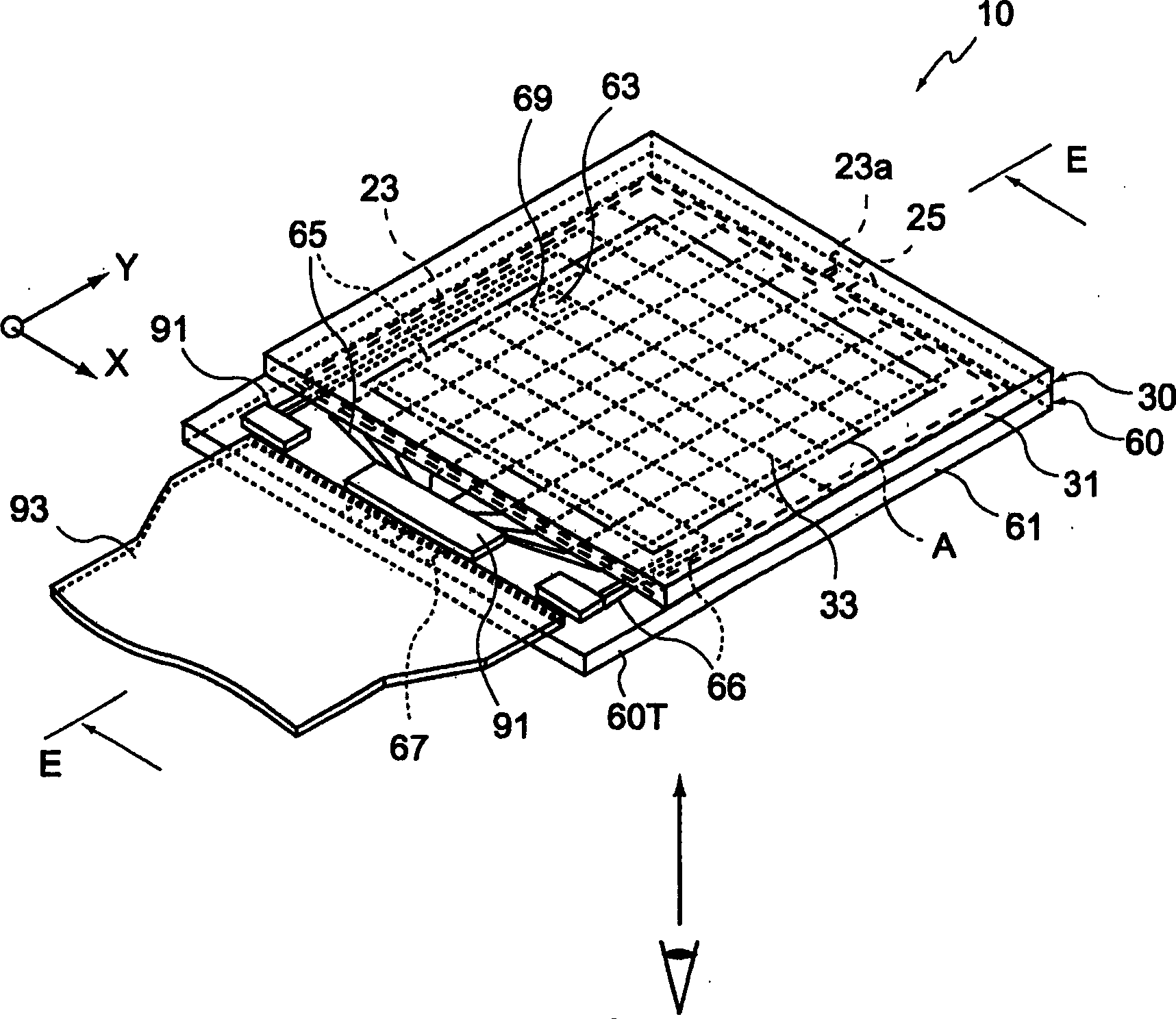

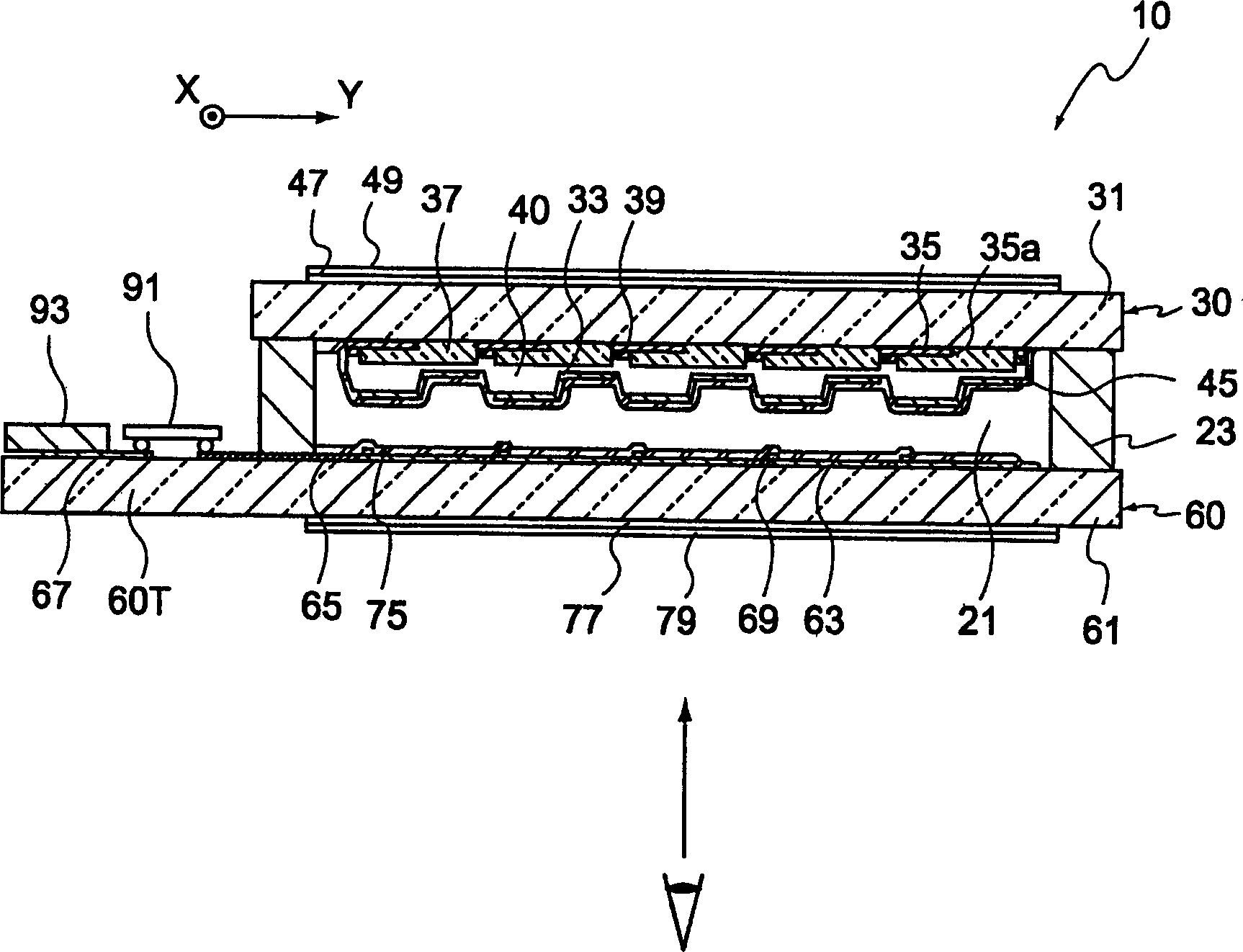

[0074] The first embodiment is a transflective liquid crystal display device comprising: a first substrate provided with a first electrode; a second substrate provided with a second electrode; and a liquid crystal material sandwiched between the first substrate and the second substrate. and a display area including a plurality of pixels, the plurality of pixels respectively have a reflective area and a transmissive area.

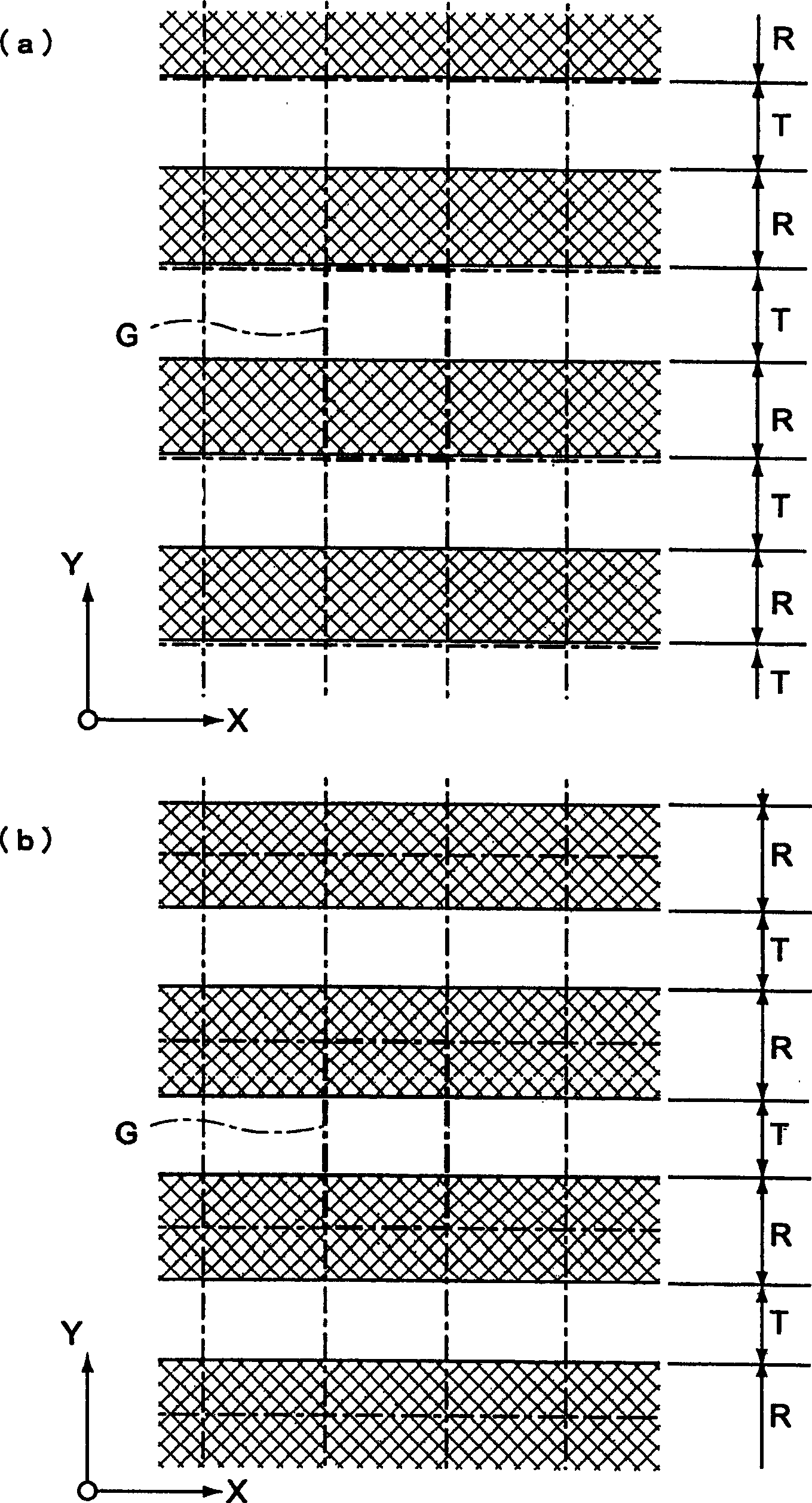

[0075] Furthermore, it is characterized in that the reflective region and the transmissive region are arranged in a strip shape across a pixel row formed by pixels arranged in one direction in the display region; An adjustment layer, the layer thickness adjustment layer has: a thick part arranged on the reflective region; and a thin part arranged on the transmissive region; The step part formed in the vertical direction, and has a relaxation part outside the display area, which is used to relax the step of the boundary between the thick layer part and the th...

no. 2 Embodiment approach

[0147] A second embodiment of the present invention is the method for manufacturing a liquid crystal display device according to the first embodiment, characterized by including:

[0148] A step of forming a photosensitive resin material layer on the first substrate;

[0149] In order to adjust the retardation in the reflective region and the transmissive region, a step of forming a layer thickness adjustment layer in which a thick part is arranged on the reflective region, a thin part is arranged on the transmissive region, and a thick layer is arranged in the display region The inclined surface of the boundary between the thick part and the thin part is formed along the vertical direction, and there is a relaxation part outside the display area, which is used to relax the step between the thick part and the thin part; and

[0150] The step of forming a first electrode on the upper layer of the layer thickness adjustment layer so that at least the first electrodes in the refl...

no. 3 Embodiment approach

[0194] A third embodiment is a transflective liquid crystal display device comprising: a first substrate provided with a first electrode; a second substrate provided with a second electrode; and a liquid crystal material sandwiched between the first substrate and the second electrode. between the substrates; and has a display area including a plurality of pixels, the plurality of pixels respectively have a reflective area and a transmissive area.

[0195] Furthermore, it is characterized in that the reflective region and the transmissive region are arranged in a strip shape across a pixel column formed by pixels arranged in one direction in the display region,

[0196] In order to adjust the retardation in the reflection area and the transmission area, the first substrate is provided with a layer thickness adjustment layer, and the layer thickness adjustment layer has: a thick layer portion arranged on the reflection area; and a thin layer portion arranged on the transmission a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com