Anti-oil leakage device of top bend needle mechanism

A technology for preventing oil leakage and bending needles, which is used in safety devices, engine lubrication, engine sealing, etc., can solve the problems of poor lubricating oil scraping effect, reduced oil leakage prevention function, and pollution of sewing machine frame, etc. Reliable effect of scraping action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

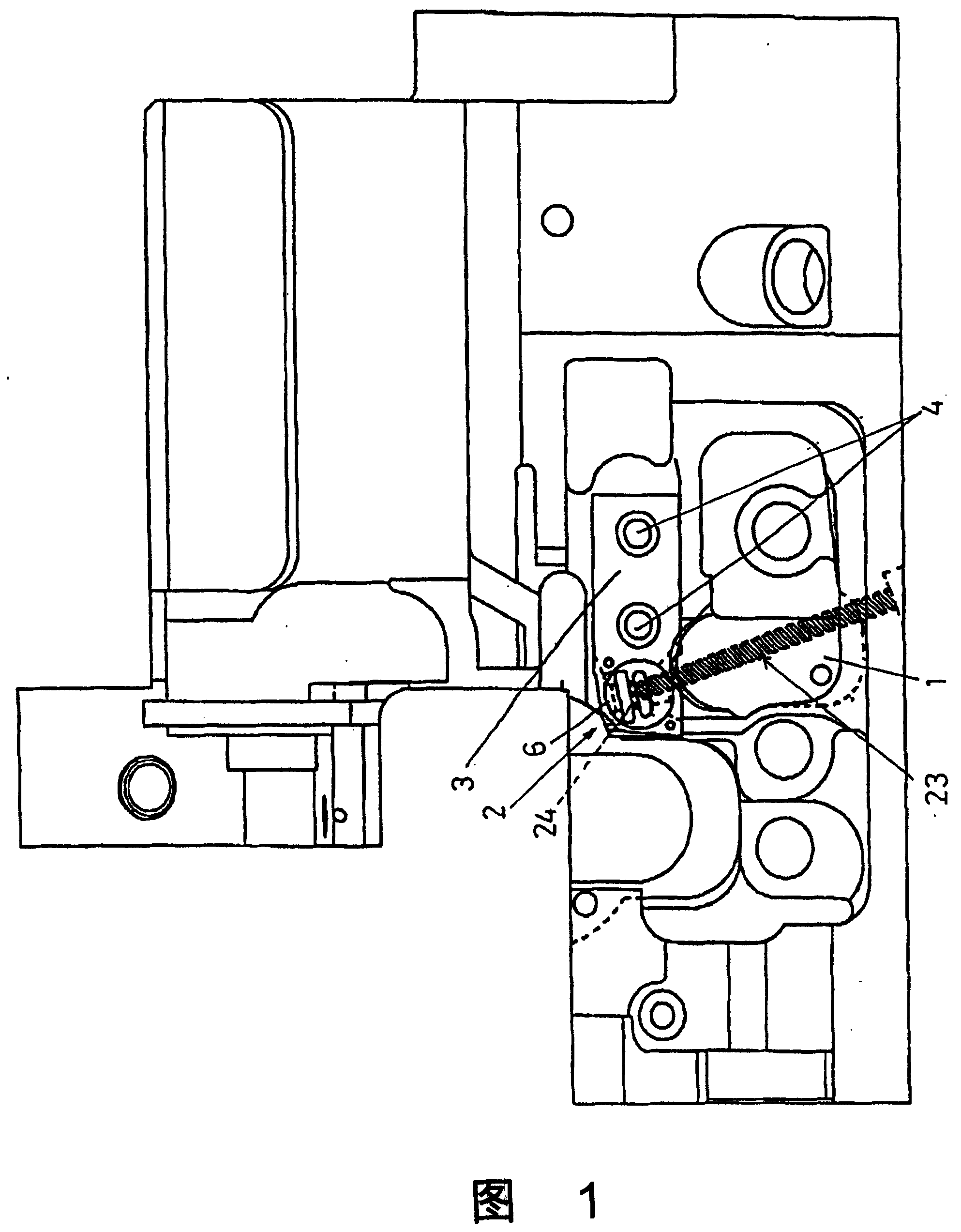

[0023] figure 1 It is a front view of the whole sewing machine frame 1 in the overlock sewing machine incorporating the oil leakage prevention device of the upper looper mechanism according to the present invention, with the machine cover installed in front of it removed, the upper looper Mechanism 2 is located in front of the sewing machine frame 1 .

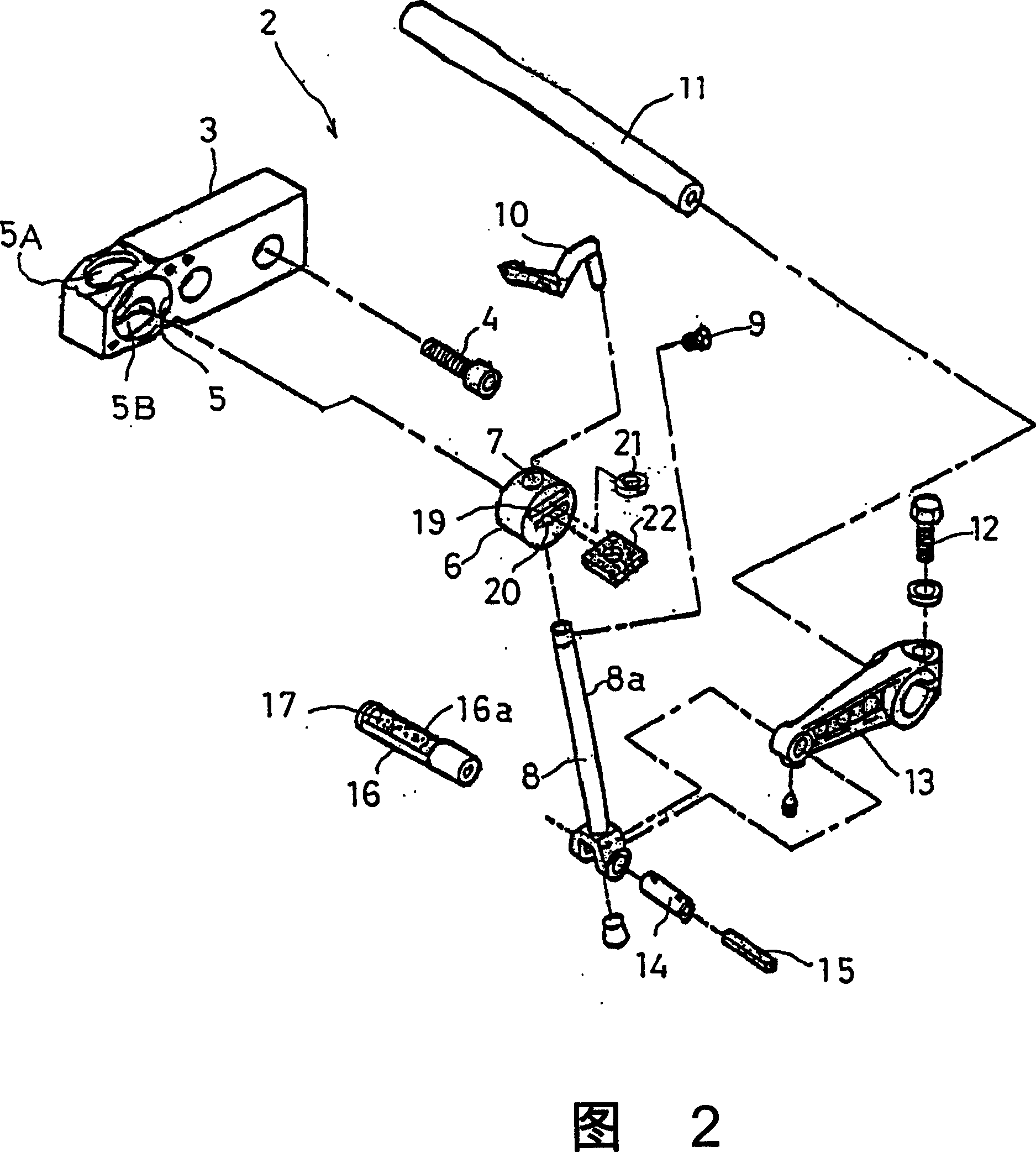

[0024] figure 2 It is an exploded perspective view of the upper looper mechanism 2, image 3 It is an assembly perspective view of the upper looper mechanism 2, Figure 4 It is a front view of the upper looper mechanism 2. In these figures, 3 is the upper looper guide part fixed on the front of the sewing machine frame 1 by fastening screws 4, and the circular hole 5 along the cloth conveying direction has holes facing the upper looper guide part 3 up and down. The state of the openings 5A, 5B on the upper surface and the lower surface is formed at the tip end portion of the upper looper guide member 3 . In the circular h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com