Apparatus and method for melting and supplying thermoplastic material to a dispenser

A technology of thermoplastic materials and plastic materials, which is applied to the device and coating of the surface coating liquid, which can solve the problems of no thermal conductivity of the tank wall and reduced material flow rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

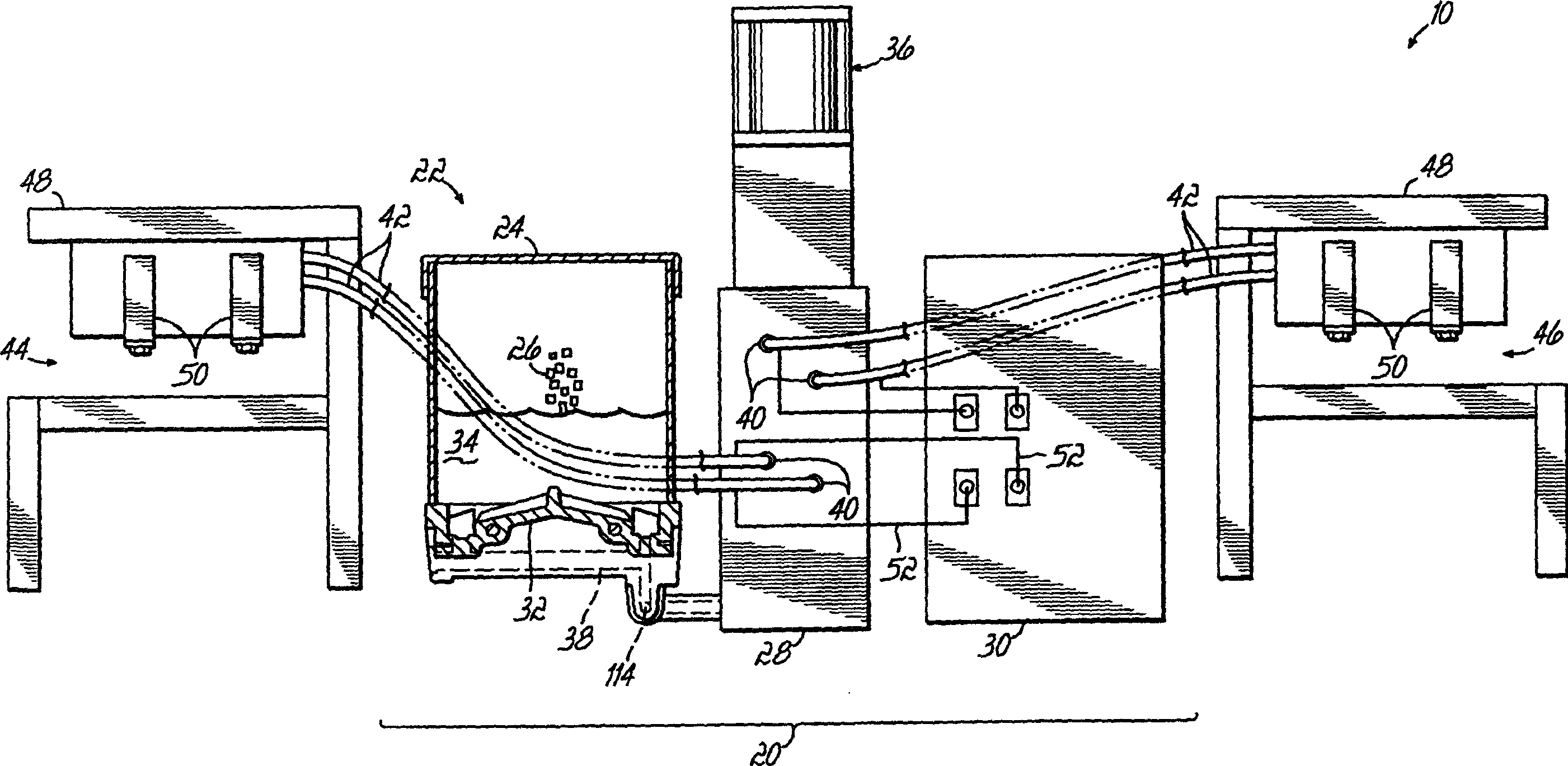

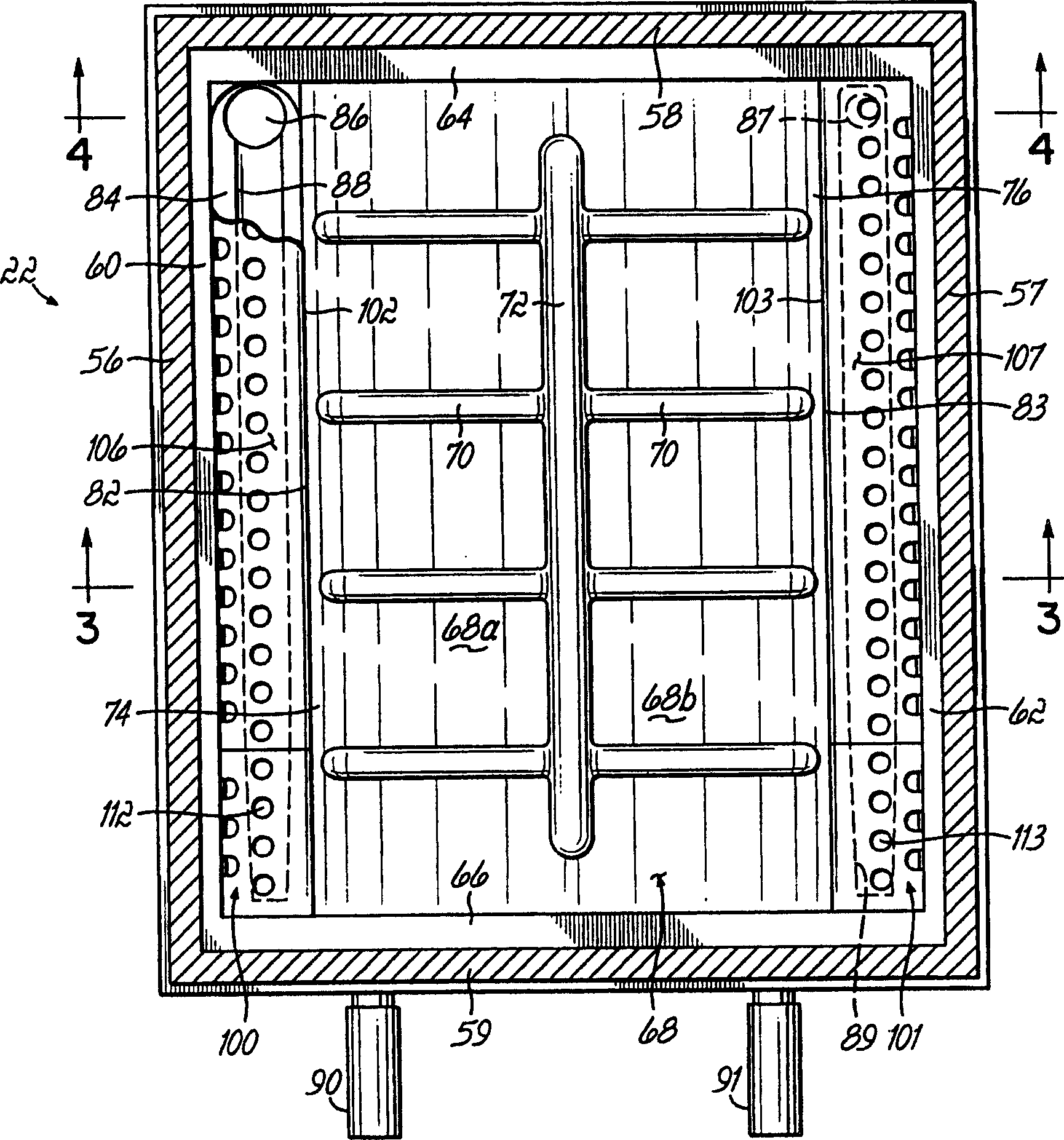

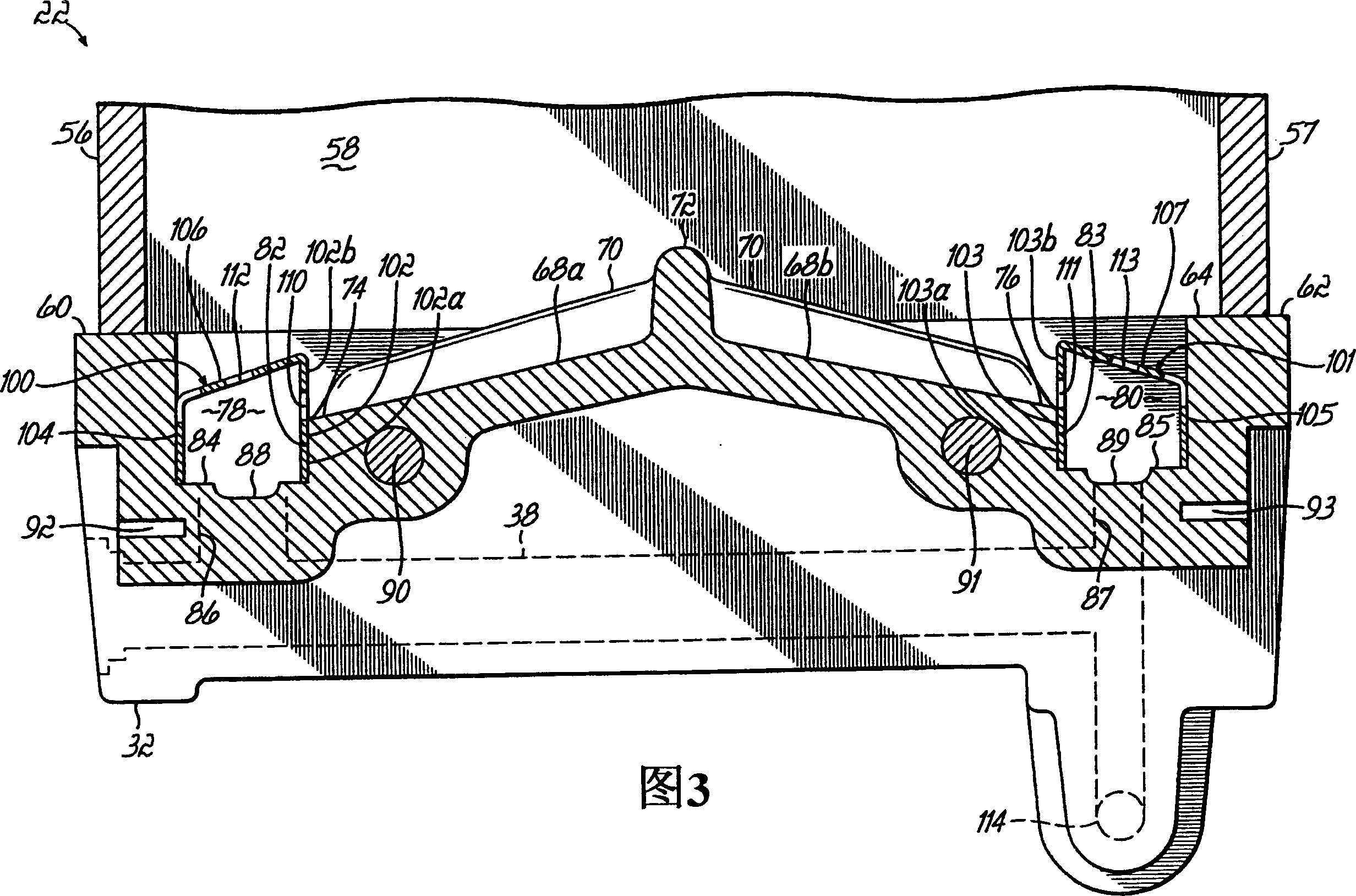

[0022] refer to figure 1 , the exemplary hot melt adhesive system 10 includes a heating apparatus, more specifically a melting apparatus 20 constructed in accordance with the principles of the present invention. The apparatus 20 includes: a tank 22 having a removable cover or lid 24 for receiving and containing thermoplastic material 26 in solid, semi-solid and liquid forms; a manifold assembly 28 connected to the tank 22; and a control unit 30 . As will be discussed in greater detail below, the tank 22 includes a base member 32 that melts the thermoplastic material 26 to form a molten liquid adhesive 34 . Pump 36 connected to manifold assembly 28 pumps liquid adhesive 34 from tank 22, through fluid passage 38, and into manifold assembly 28, where liquid adhesive 34 may be divided into separate flows . The manifold assembly 28 has outlets 40 that may be equipped with heated hoses 42 for supplying the liquid adhesive 34 to one or more dispensers 44 , 46 . The dispensers 44,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com